Two-way U-shaped bending die

A bending die and U-shaped technology, applied in the field of stamping dies, can solve problems such as low production efficiency and slow processing speed, achieve the effects of improving quality and pass rate, improving processing precision, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

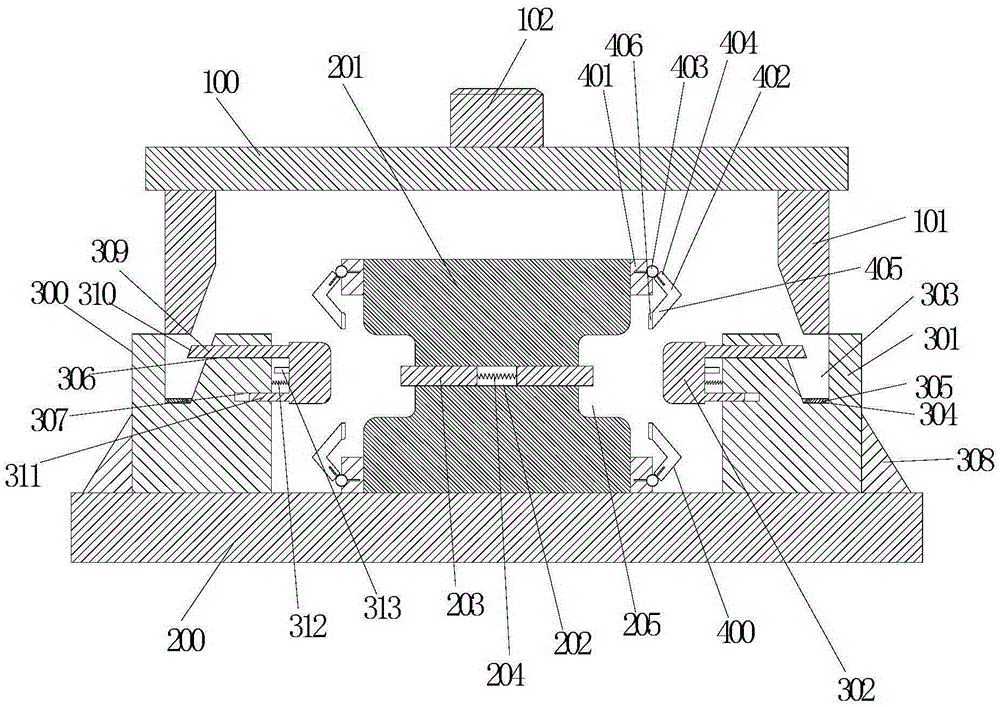

[0032] see figure 1 , the two-way U-shaped bending die provided in this embodiment includes a lower mold base 200 and an upper mold base 100, the lower mold base 200 is provided with a die 201, and the left and right sides of the die 201 are symmetrically provided with two forming grooves 205, the lower mold base 200 is symmetrically provided with a punch mechanism 300 on both sides of the die 201, the punch mechanism 300 includes a punch base 301 and a forming punch 302, the punch base 301 is fixedly connected with the lower mold base 200, and the molding The punch 302 is slidably connected with the punch base 301 , and the upper mold base 100 is provided with a wedge 101 for pushing the forming punch 302 to slide. Certainly, a mold handle 102 is also arranged on the upper mold base 100, and when the workpiece needs to be bent, the mold handle 102 is connected with a press.

[0033] When processing a workpiece, the press moves downward, and the wedge 101 pushes the forming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com