Automatic manifold production line

A production line and manifold technology, which is applied in the field of vehicle manifold processing devices, can solve problems affecting product qualification rate, low production efficiency, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

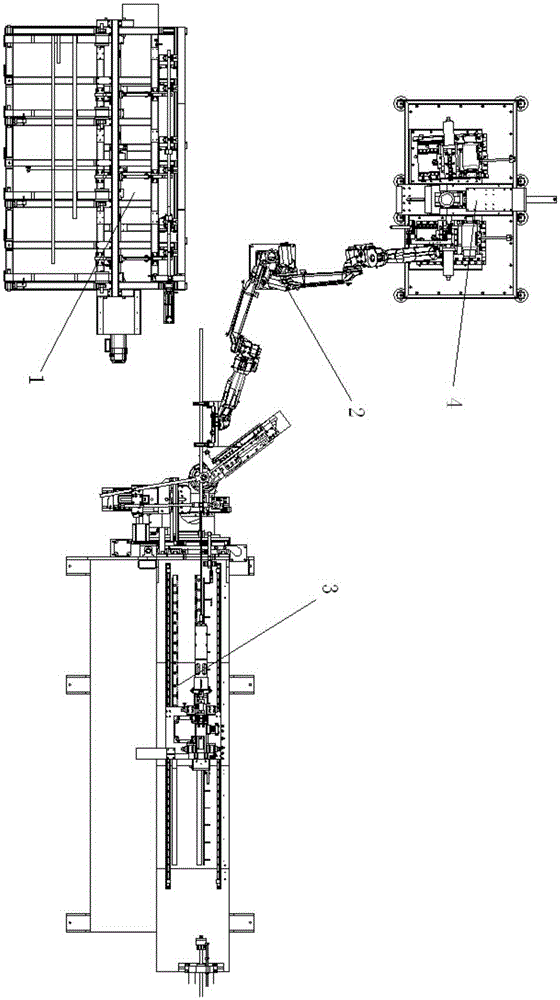

[0067] Such as figure 1 The shown automatic manifold production line includes automatic feeding equipment 1, mechanical arm 2, pipe bending equipment 3 and pipe end forming equipment 4. The mechanical arm 2 is used as a pipe conveying device, and the mechanical arm 2 automatically loads The pipe material in the material equipment 1 is transported into the pipe bending equipment 3 and the pipe end forming equipment 4 in sequence. When working, operate the crane to place the whole bundle of pipe material into the automatic feeding device 1, remove the bundled material facility, make the pipe material into a natural state, start the automatic feeding device 1 for feeding, and then pass the automatic feeding device 2 through the mechanical arm 2. The pipe material loaded by the feeding device 1 is transported into the pipe bending device 3, and the pipe material is first bent in the pipe bending device 3, and then the bent pipe material is cut off to remove the excess pipe materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com