Automatic sealing strip pasting device of cleaning bag

A technology of cleaning bags and sealing strips, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of unfavorable automatic production of cleaning bags, large manual labor, high labor costs, etc., achieve compact production and improve placement Quality, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

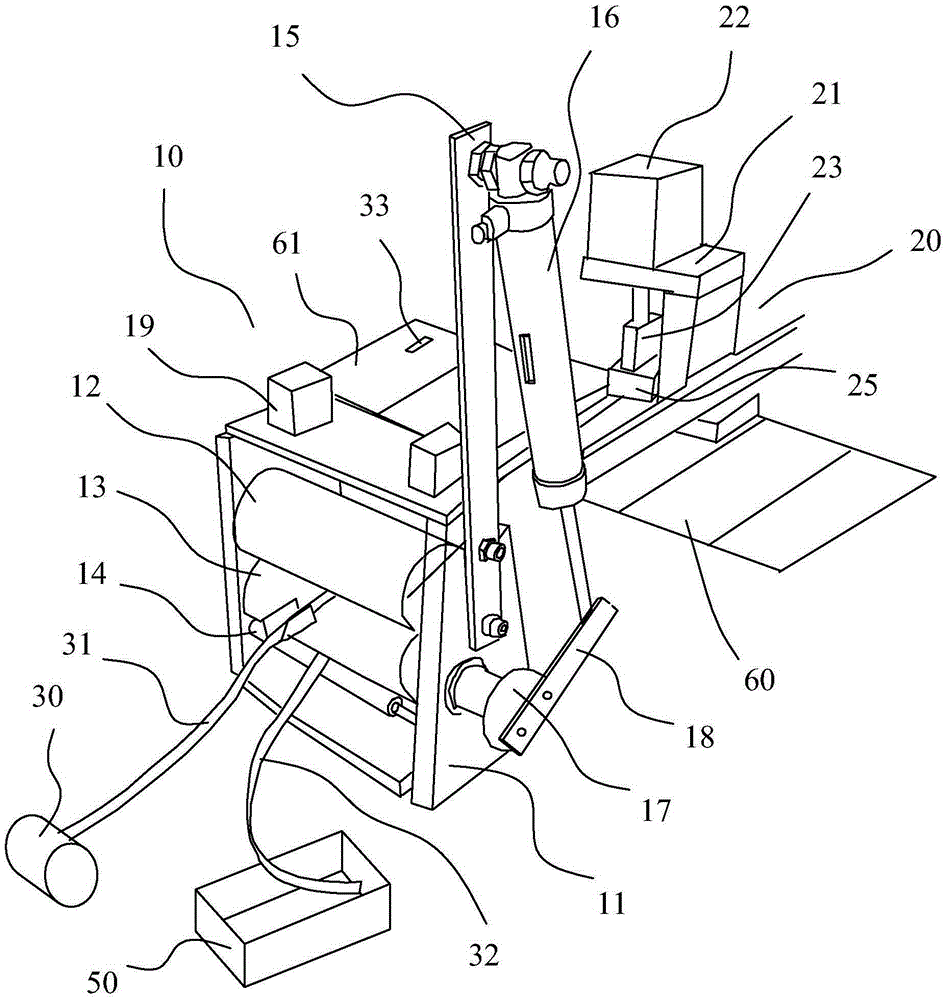

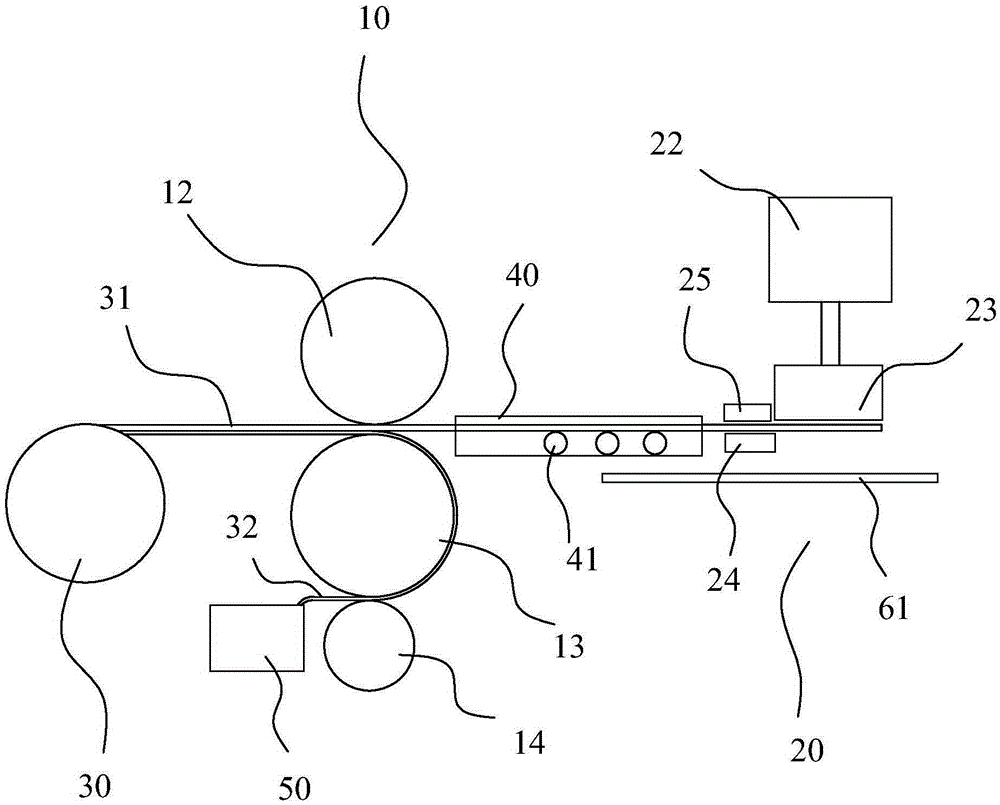

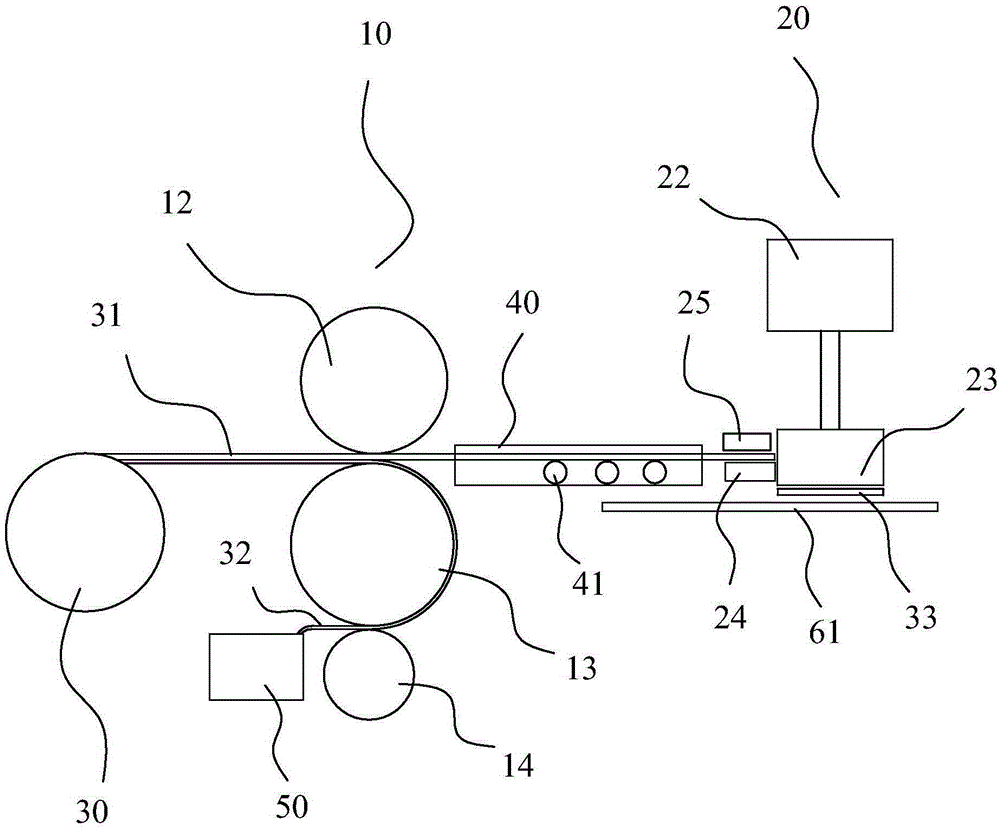

[0032] As shown in Figures 1-3, a cleaning bag automatic sealing strip device includes a sealing strip mechanism 20 and a feeding mechanism 10 for delivering the sealing strip to the sealing strip mechanism 20, and the feeding mechanism 10 includes a feeding support 11. The main feeding roller 12, the auxiliary feeding roller 13, the feeding power source 16 and the peeling roller 14 for peeling off the release paper 32 on the sealing strip 31, the main feeding roller 12, the auxiliary feeding roller 13 and the peeling roller 14 It is arranged side by side on the feeding support 11, and the feeding auxiliary roller 13 and the stripping roller 14 are respectively located on both sides of the feeding main roller 12, and the gap between the feeding main roller 12 and the feeding auxiliary roller 13 forms a sealing strip 31, the gap between the main feed roller 12 and the peeling roller 14 forms a discharge channel for the release paper 32. The main feeding roller 12 is driven to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com