A tire pattern and high-performance radial car tire based on bionic non-smooth structure

A kind of tire pattern, non-smooth technology, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc. The phenomenon of ditch bottom crack failure, the effect of improving water skiing speed and good ground grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

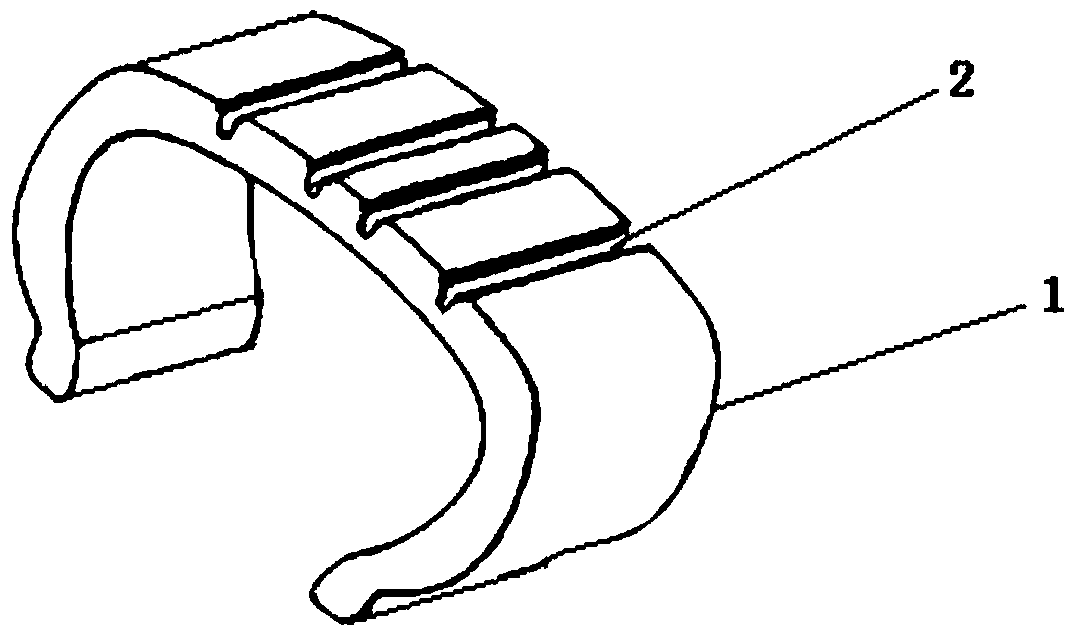

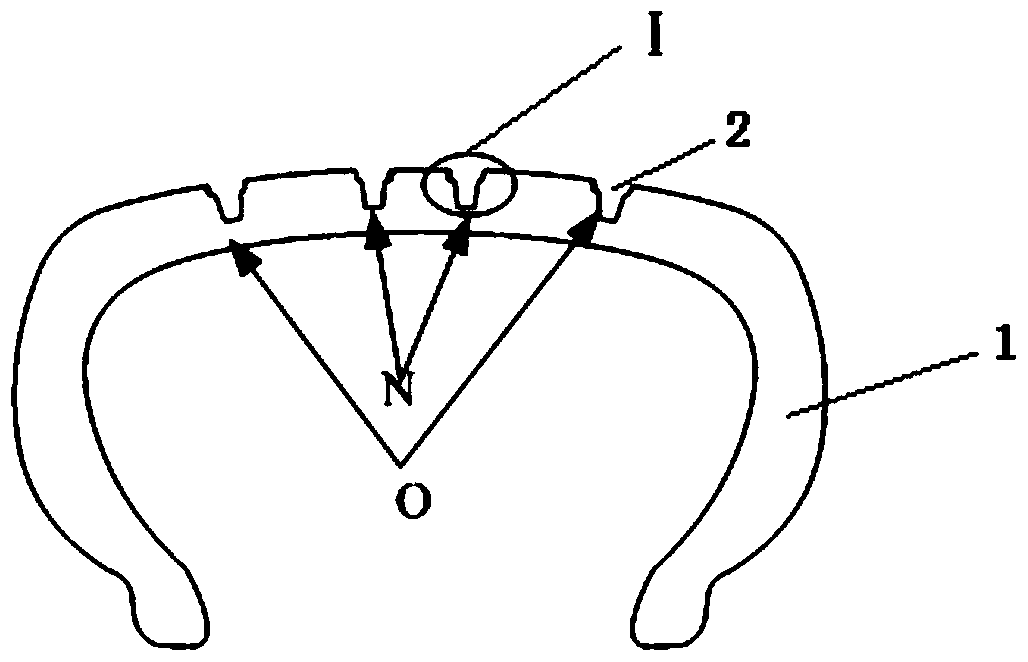

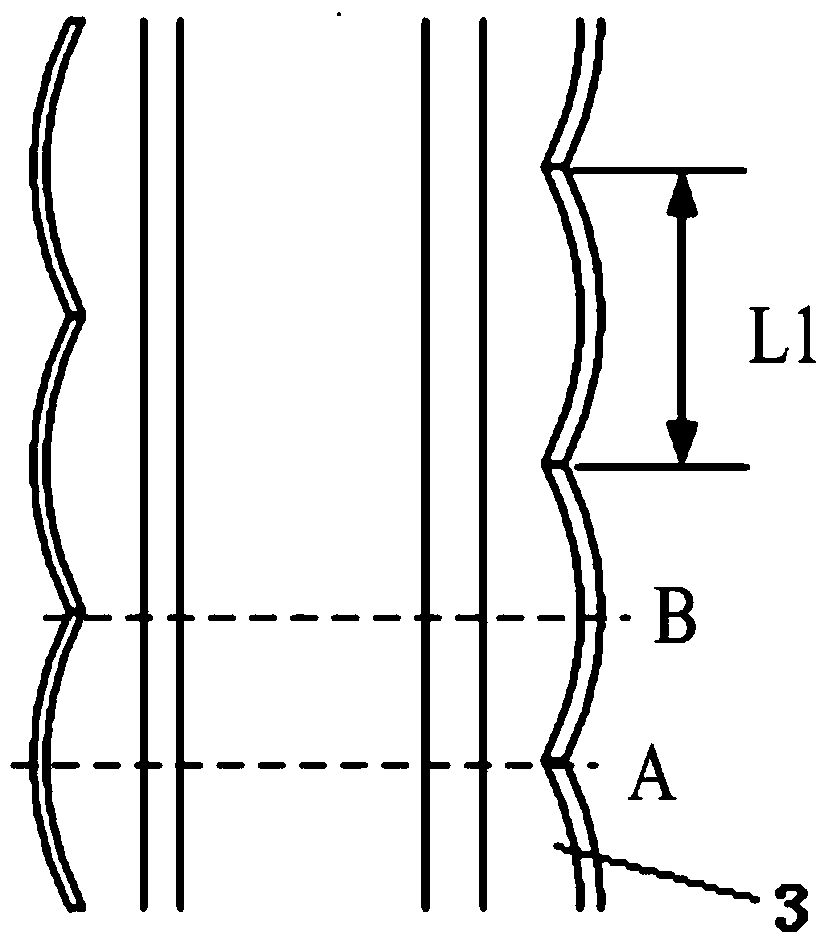

[0026] The tread pattern groove based on the bionic non-smooth structure of the present invention is suitable for high-performance radial car tire 1, such as figure 1 As shown, the tire pattern based on the bionic non-smooth structure is modified on the basis of the original four high-performance longitudinal grooves 2, the depth of the longitudinal grooves 2 is 8-10 mm, and the width is 6-8 mm. The side walls of the longitudinal grooves 2 all form an included angle of 5°-10° with the radial plane of the tire. The sidewall has streamlined pattern grooves 3 whose section is continuously arranged along the tire circumferential direction. The arc length L of the wall surface of the streamlined pattern groove 3 in the axial direction of the tire 1 6° / 360°×L, where L is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com