Indoor electric heating drying component

An electric heating and resistance heating technology, which is applied in the field of indoor electric heating drying components and household products, can solve the problems of drying objects with a damp feeling, insufficient drying of drying objects, and difficult drying of drying objects, and achieves convenient drying and simple structure. , the effect of large drying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

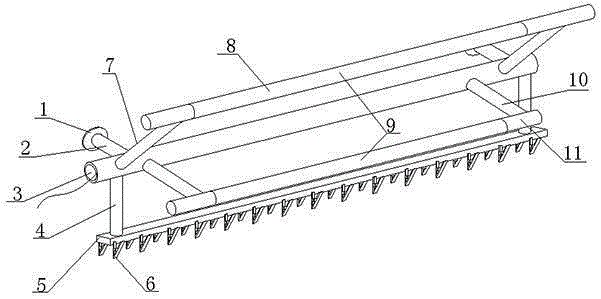

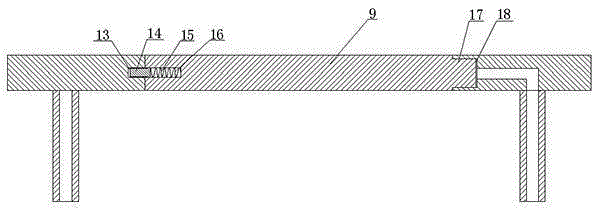

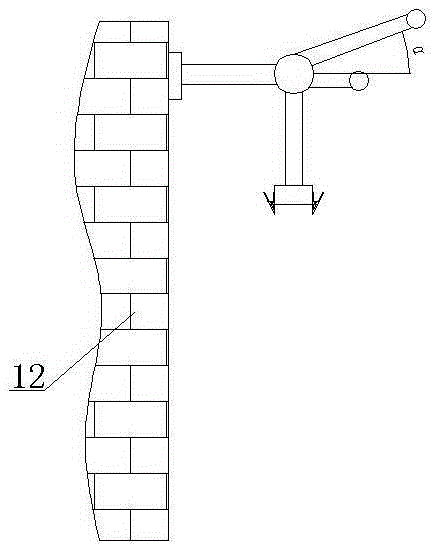

[0017] Such as Figure 1-Figure 3 The described indoor electric heating drying assembly includes a hollow fixed rod 3, the hollow fixed rod 3 is connected to the fixed plate 1 through the horizontal connecting rod 2, and the lower end of the hollow fixed rod 3 is connected to the lower end through the vertical rod 4. Both sides of the splint 5 and the lower splint 5 are provided with a plurality of clips 6 along the axial direction, and the hollow fixing rod 3 is also provided with a horizontal hollow support rod 10 relative to the horizontal connecting rod 2, and the horizontal hollow support rod 10 is connected with a lower parallel The object drying rod 11, the hollow fixed rod 3 is located at the upper end of the horizontal hollow support rod 10 and is also provided with a hollow inclined support rod 7, the hollow oblique support rod 7 is connected with an upper parallel object drying rod 8, and the upper parallel object drying rod 8 is located at the lower parallel The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com