Liquid injection system capable of automatically sealing coal body around extraction drill hole and method of application

A technology for automatic sealing and drainage of boreholes, applied in sealing/seal, mining equipment, mining equipment, etc., can solve the problem of gas leakage in boreholes, affect the efficiency of gas drainage, and cannot effectively improve the efficiency of gas drainage in boreholes and other problems to achieve the effect of improving extraction efficiency and saving extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

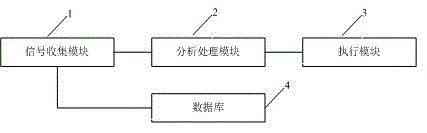

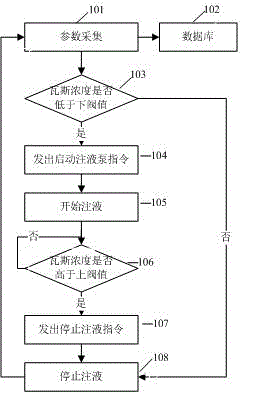

[0020] figure 1 It is a structural schematic diagram of a liquid injection system for automatically sealing and extracting coal around the borehole of the present invention. Such as figure 1 As shown, the liquid injection system for automatically sealing the coal body around the gas drainage borehole of the present invention may specifically include: a signal collection module 1 , an analysis and processing module 2 , an execution module 3 and a database 4 .

[0021] Among them, the signal collection module 1 is used to collect gas drainage parameters in the underground gas drainage process, which may include: orifice temperature, gas concentration, gas flow rate and orifice negative pressure parameters; analysis and processing module 2 is used to obtain received signals Collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com