New acting system of direct-injection diesel engine

A diesel engine and power technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as hindering piston operation, large emissions, fire, etc., to optimize combustion work time and space, optimize combustion space, and improve power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

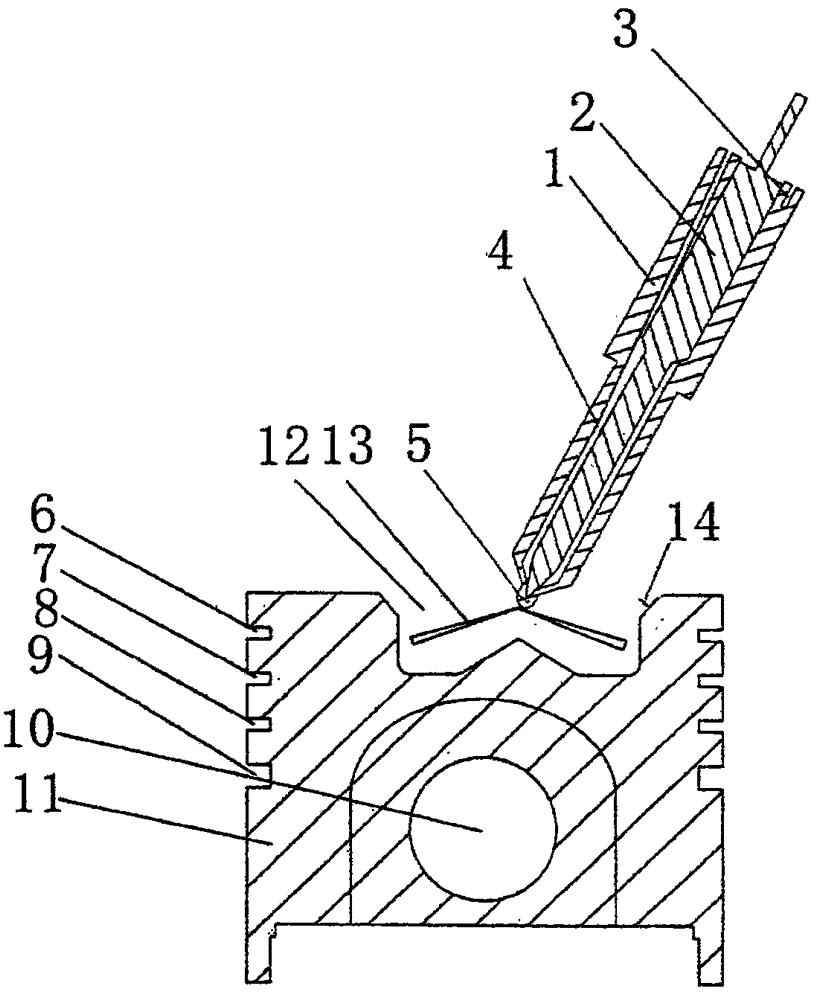

[0020] Realize the combustion work time of optimal optimization diesel engine, be to rely on the new type piston combustion chamber (12) of the work new system of direct injection diesel engine and the new type fuel injector to finish. First, after the quantitative change of the volume of the combustion chamber, the diesel engine is burned at 2 degrees before the top dead center to 2 degrees after the top dead center, that is, the volume of the new piston combustion chamber (12) of the new work system of the direct injection diesel engine makes the diesel engine burn at the same time after the quantitative change of the volume of the combustion chamber. The pressure at 3 degrees before top dead center is not enough, resulting in the high temperature caused by high pressure cannot make the atomized oil burn, and it will burn at 2 degrees; at the same time, the new fuel injector completes the work at 2 degrees before top dead center to evenly distribute the fuel required for work....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com