Clutch/brake integrated assembly and automatic gear switching method thereof

A technology of brakes and clutches, applied in the combination of couplings and brakes, mechanical equipment, etc., can solve the problems of inability to realize power shifting, etc., and achieve the effect of small size, simple and compact structure, and a small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

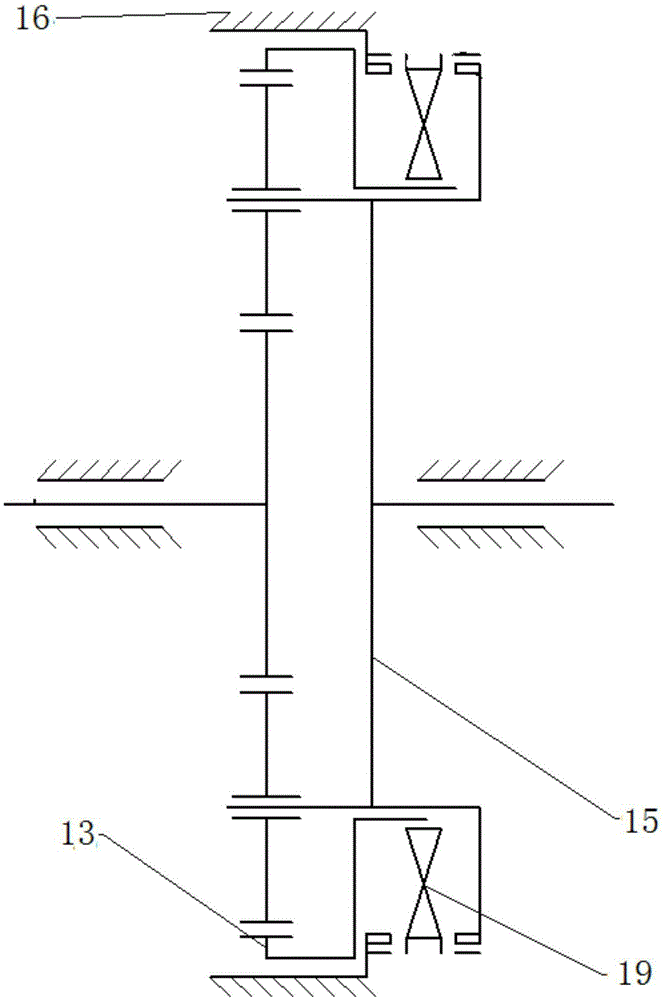

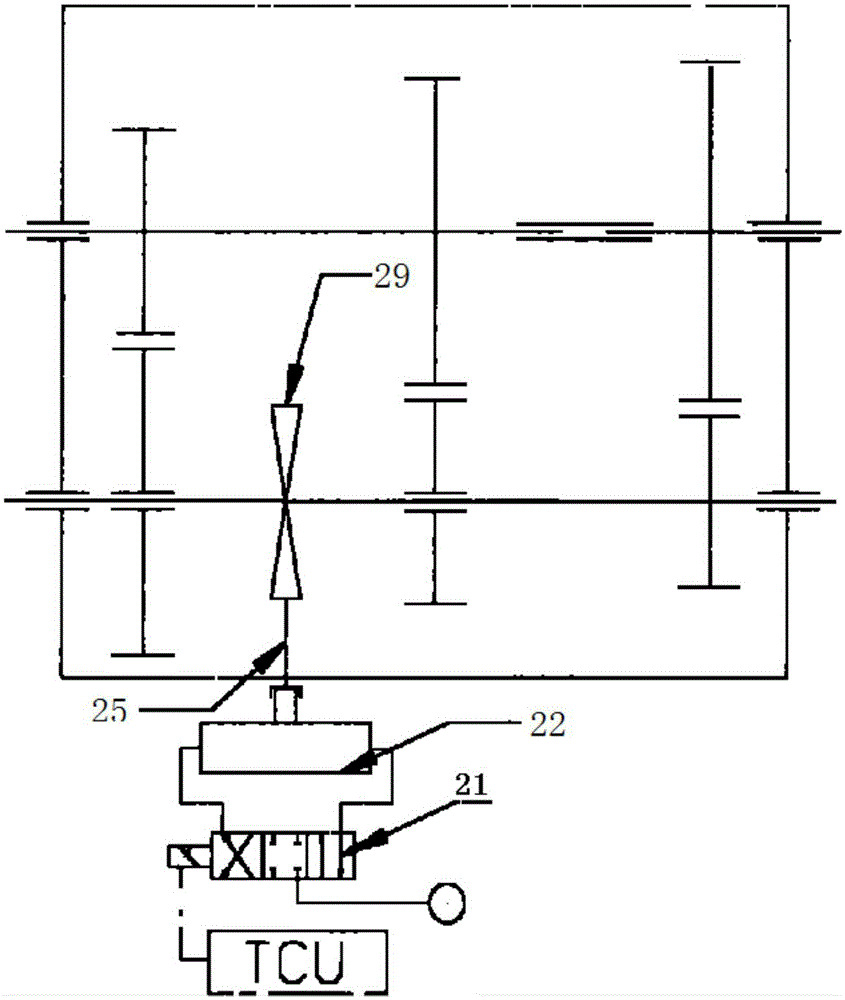

[0033] figure 1 , figure 2 for existing technology. For details, refer to the background technology section.

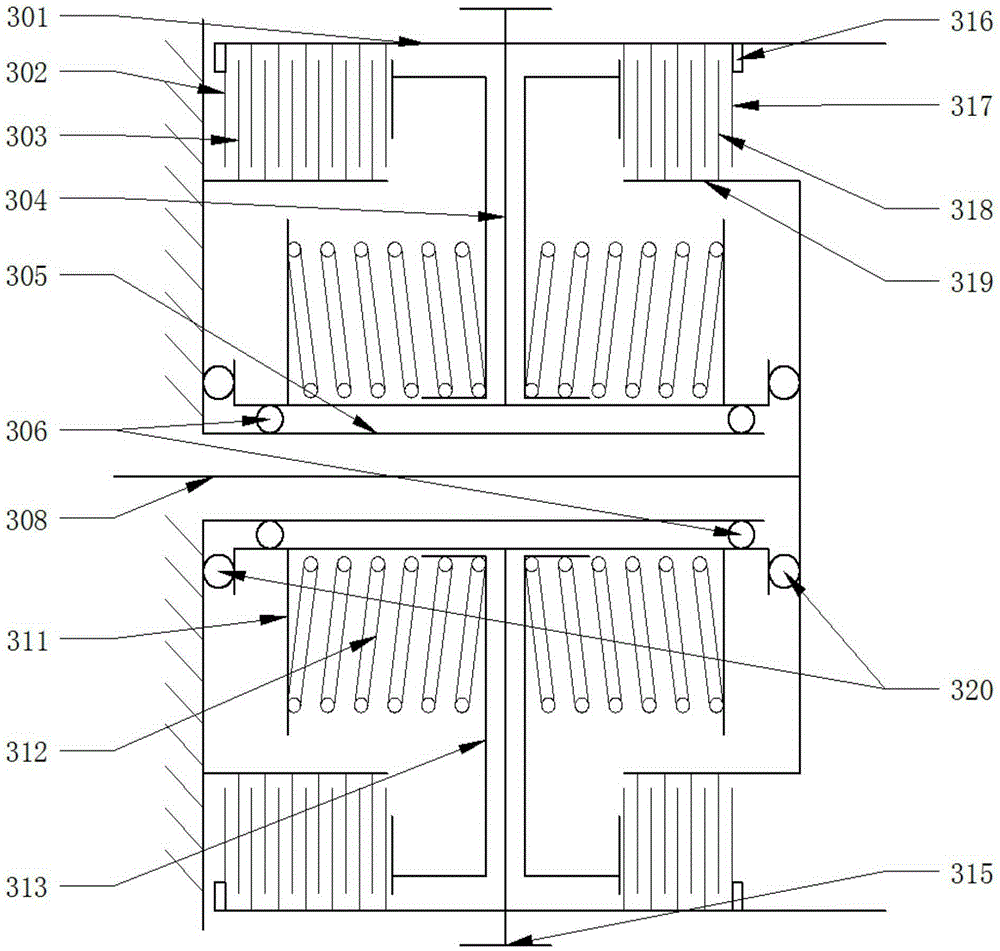

[0034] Combine below image 3 , Figure 4 Describe the main structure of the clutch / brake integrated assembly of the present invention, which adopts two hydraulic wet multi-disc friction clutches (two sets of hydraulically driven wet multi-disc friction assemblies are integrated axially), including an integrated clutch drum 301, clutch Hub 319, brake friction assembly, clutch friction assembly, oil inlet bushing 305, hydraulic cylinder 304, piston 313, return spring 312, spring seat 311, R-type expansion ring seal ring 310 and O-type seal ring 314;

[0035] The integrated clutch drum 301 is rigidly connected with the (tandem) hydraulic cylinder 304, and the piston 313, return spring 312 and spring seat 311 are sequentially installed in the hydraulic cylinder 304;

[0036] The hydraulic cylinder 304, the piston 313 and the O-ring 314 form two axially arranged hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com