Lapped thermal shrinkage round pipe

A heat-shrinkable, round tube technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of large thickness of the lap joint and inconvenient sewing operation of the lap joint, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

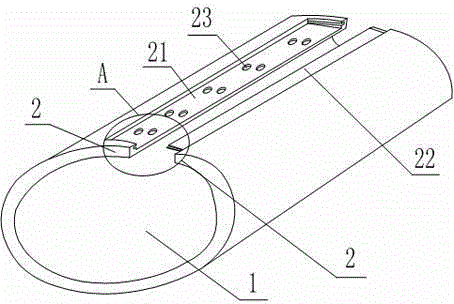

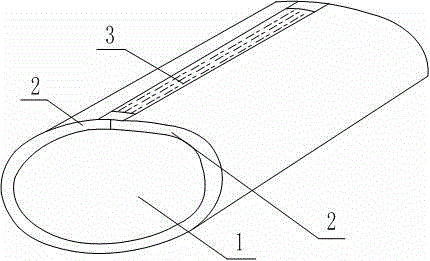

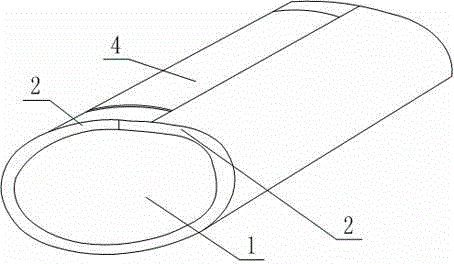

[0025] Such as Figure 1 to Figure 4 As shown, the overlapping heat-shrinkable circular tube is rolled into a tubular shape from a sheet-shaped heat-shrinkable material 1, and the tubular shape includes two overlapping sections 2, and a U-shaped groove 21 is provided on the outside of one of the overlapping sections 2, and the U-shaped The two sidewalls of the groove 21 are symmetrically provided with two draw-in grooves 24, and the outside of the other lap section 2 is provided with a boss 22 cooperating with the U-shaped groove 21, and the two ends of the boss 22 are provided with a draw-in groove 24. Convex 25, the outer side of described lap section 2 is provided with suture 3 that sutures U-shaped groove 21 and boss 22 together, and the outside of suture 3 is provided with heat-sealing layer 4; Said suture 3 selects nylon for use, can also Is nylon, polyester or aramid.

[0026] The working process of the present invention: before the lap section 2 is sutured, the boss 2...

Embodiment 2

[0028] Such as Figure 1 to Figure 4 As shown, this embodiment is based on Embodiment 1, the bottom of the U-shaped groove 21 is provided with a groove 23, and the inner side of the boss 22 is provided with a protrusion that cooperates with the groove 23; The height of the side wall is 1 / 2 of the sheet-like heat-shrinkable material 1, and there are three sutures 3; the diameter of the suture 3 is 0.4mm; the groove 23 is a hemispherical structure, which can also be Ellipsoid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com