Laser de-weight dynamic balance device and method applied to rotation workpiece

A technology of rotating workpieces and balancing devices, which is applied in the direction of static/dynamic balance testing, measuring devices, and testing of machine/structural components. The effect of balancing time, reducing labor intensity, and high accuracy of deduplication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

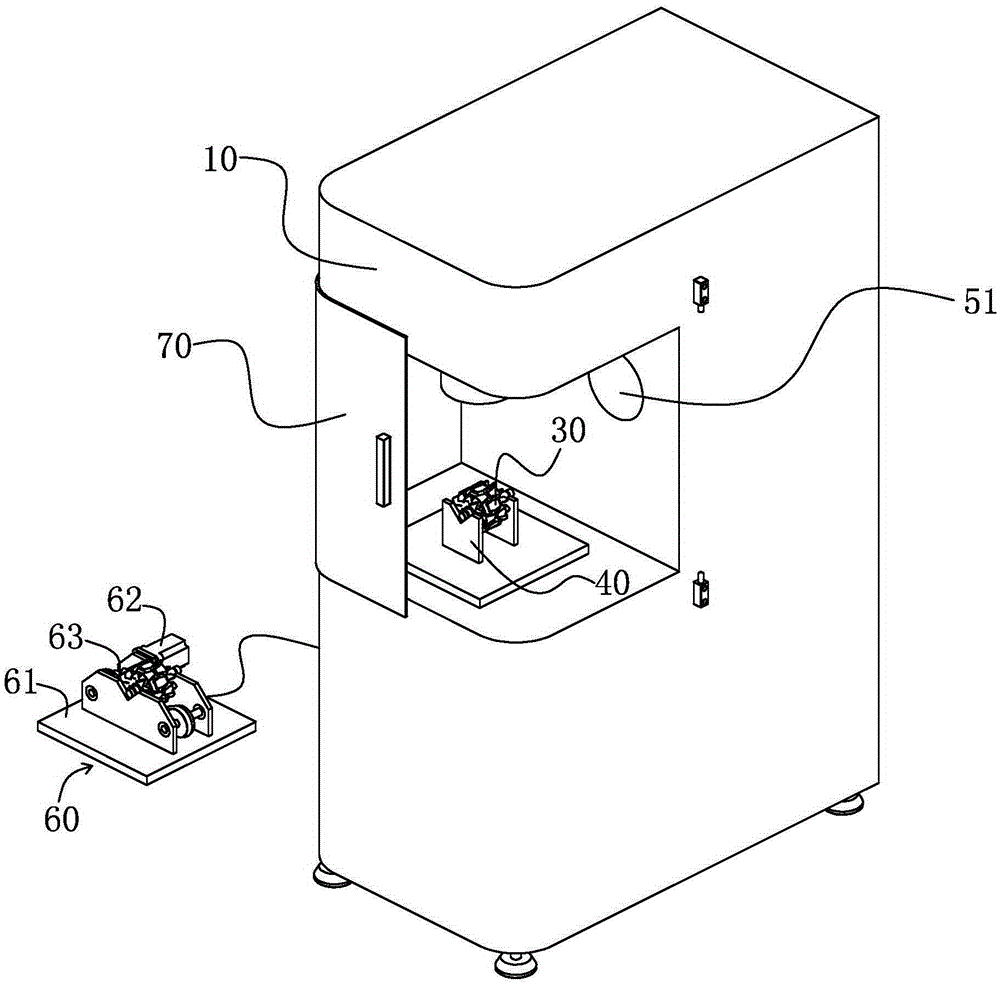

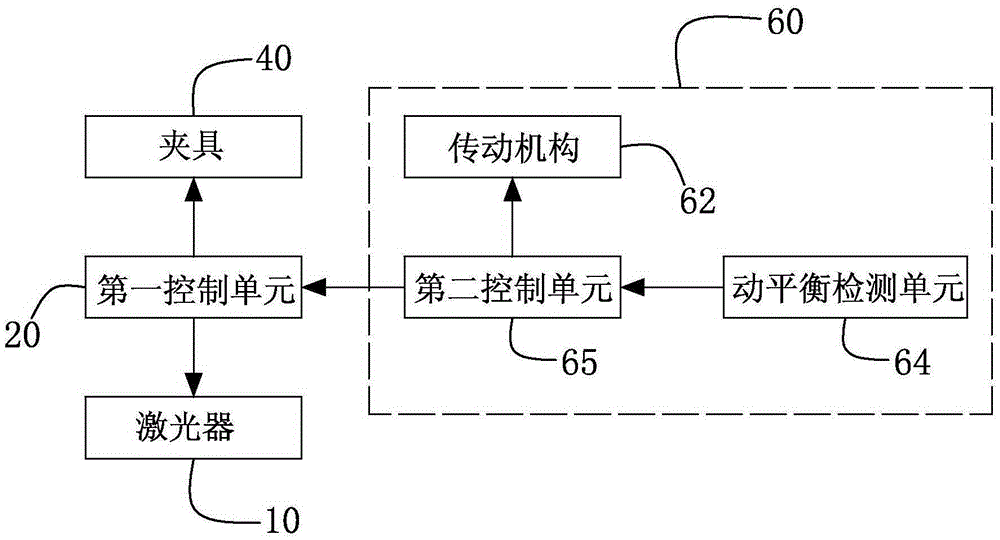

[0037] see figure 1 and image 3 , The laser deweighting and dynamic balancing device for rotating workpieces in this embodiment includes a frame, a laser 10 , a first control unit 20 , a rotating workpiece 30 , a fixture 40 , an exhaust device and a dynamic balance detection device 60 . In this embodiment, the rotating workpiece 30 is one of a magnetic or non-magnetic motor rotor, generator rotor or machine tool spindle, and of course it can also be other workpieces requiring dynamic balance.

[0038] like figure 1 As shown, the frame of this embodiment is a box-type frame, and a movable door 70 for picking and placing the rotating workpiece 30 is provided on one side of the frame. The dodge door 70 is a manual or automatic door, which can be a sliding door or a swing door, and a handle is provided on the door to facilitate the opening / closing of the dodge door. When the rotating workpiece 30 needs to be taken and placed, the dodge door 70 is opened, and when working, the do...

Embodiment 2

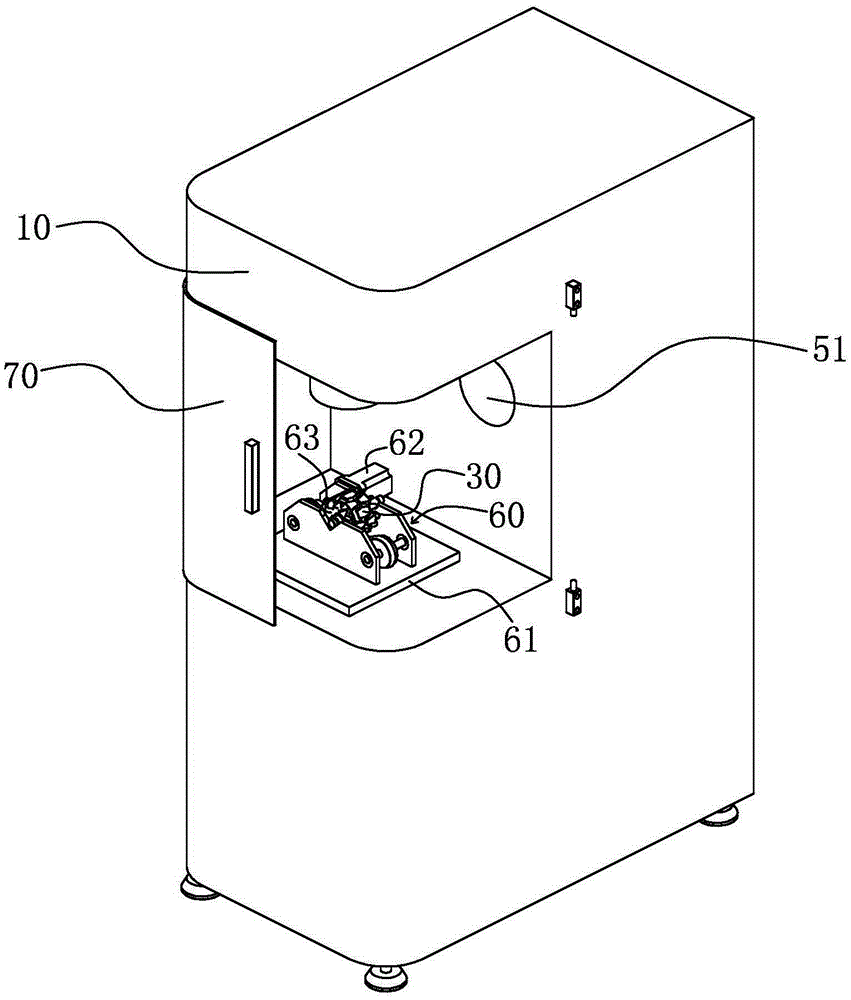

[0059] see figure 2 and Figure 4 , the laser deweighting and dynamic balancing device for rotating workpieces in this embodiment includes a frame, a laser 10 , a first control unit 20 , a rotating workpiece 30 , an air exhaust device and a dynamic balance detection device 60 . In this embodiment, the rotating workpiece 30 is one of a magnetic or non-magnetic motor rotor, generator rotor or machine tool spindle, and of course it can also be other workpieces requiring dynamic balance.

[0060] like figure 2 As shown, the frame of this embodiment is a box-type frame, and a movable door 70 for picking and placing the rotating workpiece 30 is provided on one side of the frame. The dodge door 70 is a manual or automatic door, which can be a sliding door or a swing door, and a handle can also be arranged on the door to facilitate the opening / closing of the dodge door. When the rotating workpiece 30 needs to be taken and placed, the dodge door 70 is opened, and when working, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com