Method for calculating maximum circumferential stress of annular valve plate with different thicknesses of hydro-pneumatic spring

A technology of circumferential stress and oil-gas springs, applied in the field of oil-gas springs, can solve problems such as unsatisfactory and lack of analytical calculation formulas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

[0027] The present invention will be further described in detail through an embodiment below.

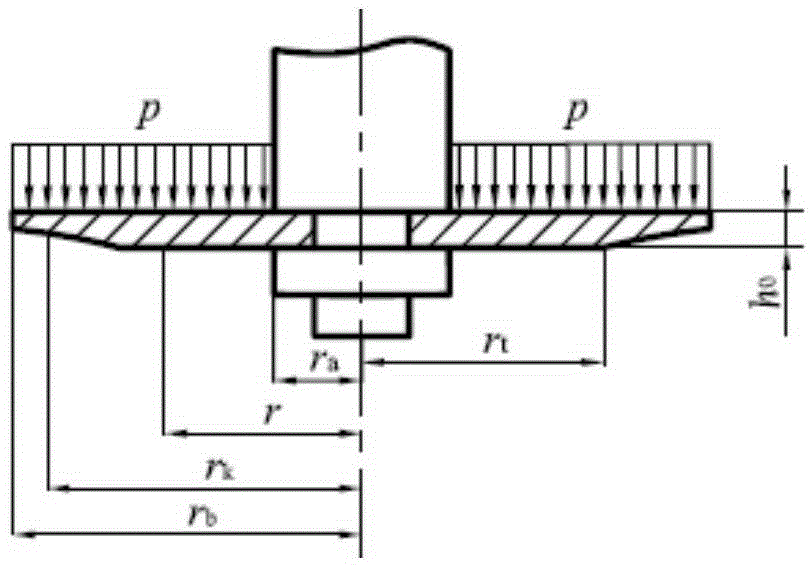

[0028] The oil and gas spring of a special vehicle adopts annular valve discs of unequal thickness, the elastic modulus E = 200GPa, Poisson's ratio μ = 1 / 3, and the thickness of the equal thickness part is h 0 =0.3mm, variable thickness radius r t =7.3mm, effective inner circle radius r a =5.0mm, outer circle radius r b =8.5mm, the uniform pressure received is p=3.0MPa.

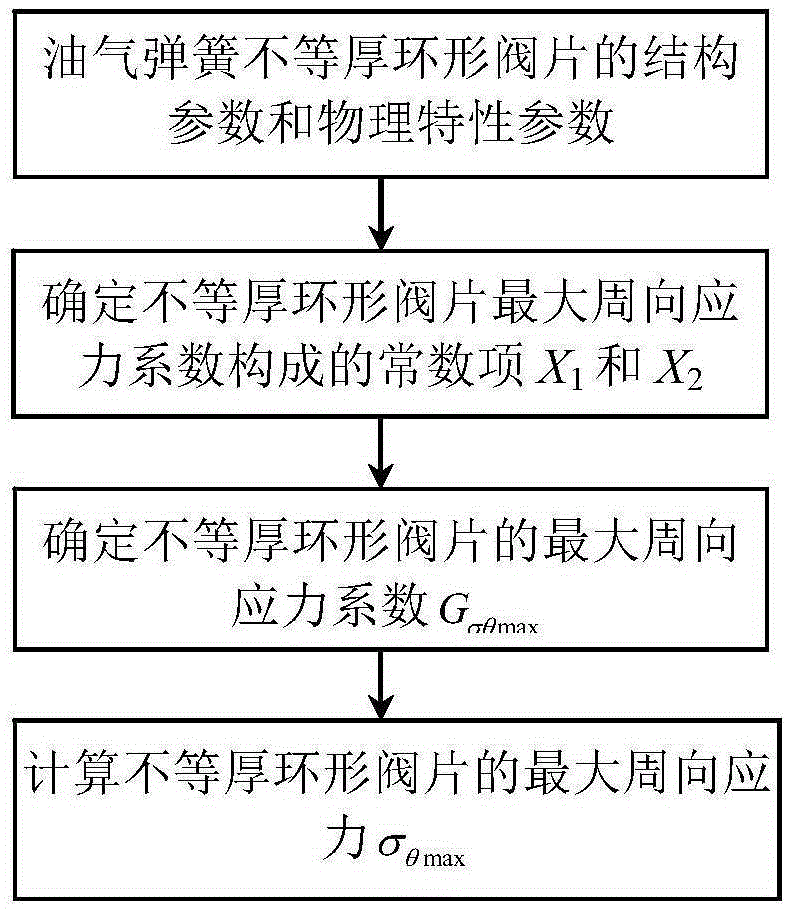

[0029] The calculation method of the maximum circumferential stress of the oil-gas spring unequal thickness annular valve plate provided by the example of the present invention, its calculation flow chart is as follows figure 1 As shown, the mechanical model of the oil-gas spring unequal-thickness annular valve plate is as follows figure 2 As shown, the specific steps are as follows:

[0030] (1) Determine the constant term X formed by the maximum circumferential stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com