Corn cob picking device with quick-return characteristic and manual work simulation function

A corn ear and corn technology, which is applied in the field of corn ear breaking device and corn ear breaking principle, can solve the problems of poor practicability, high energy consumption, complex structure, etc., and achieve low energy consumption, good bionic effect and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

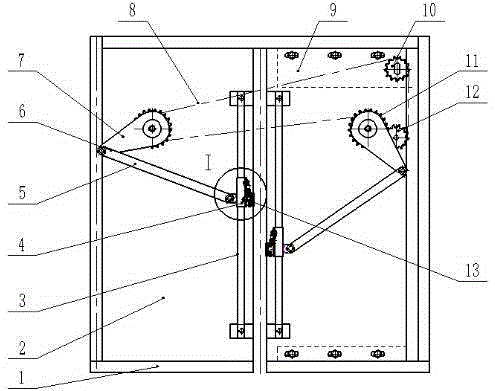

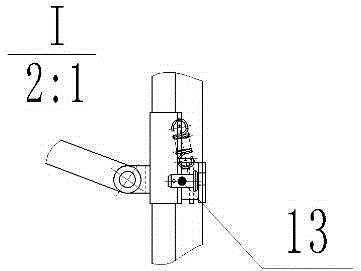

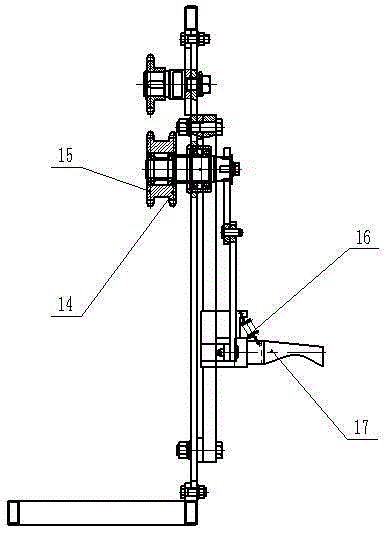

[0014] The fringe breaking mechanism is installed in front of the harvester, and the harvester drives the mechanism to work. The movable plate (9) and the fixed plate (2) are installed on the frame (1), and the input sprocket (14) and the driving sprocket (15) are coaxially installed above the fixed plate (2); the driven sprocket (11 ), tensioning sprocket 1 (10) and tensioning sprocket 2 (12) are installed on the movable plate (9); and on the fixed plate (2), the fringe breaking slideway (3) needs to ensure the plumb weight, and the two sets of cranks (7) are connected coaxially with the driven sprocket (10) and the driving sprocket (15) respectively through splines. , the other end of the crank (7) is connected to the connecting rod (7), the other end of the connecting rod (7) is connected to the slider (4), and the tassel breaking hand (17) is installed on the slider (4).

[0015] When working, the engine drives the driving sprocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com