Machining method for casing casting part

A technology of mechanical processing and casting, applied in the field of mechanical processing of parts, can solve the problems of backward casing casting processing technology, low production efficiency, poor processing quality, etc., to improve processing quality, save fitter marking links, processing The effect of high technical precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

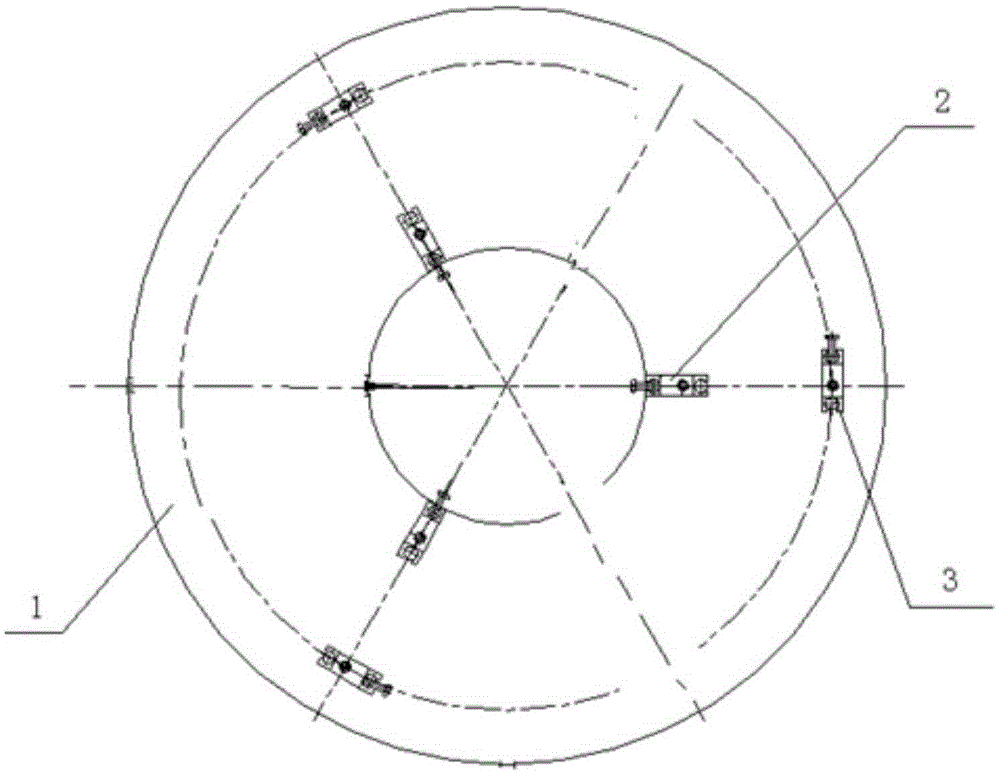

[0016] Such as Figure 1~4 Shown, a kind of machining method of casing casting, comprises the steps:

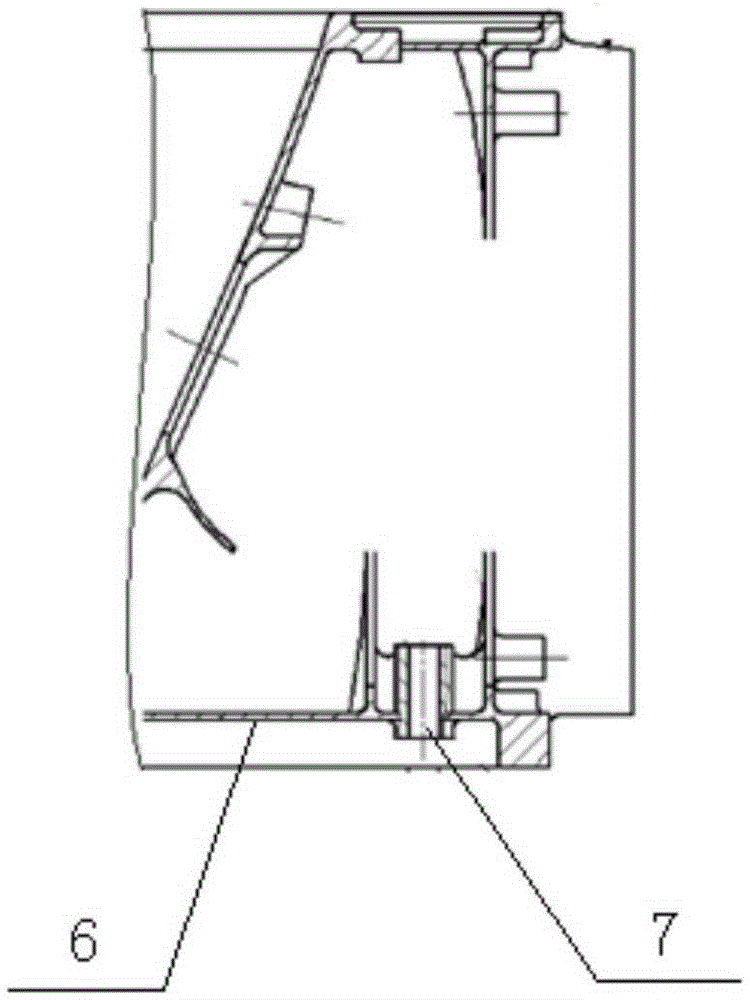

[0017] 1. Casting processing benchmark: design the raw material drawing of the casing casting according to the design drawing of the casing parts, determine three positioning surfaces 6 and positioning holes 7 on the rear end surface of the casing casting, and accurately cast the casing casting on the casing casting. Three positioning surfaces 6 and positioning holes 7;

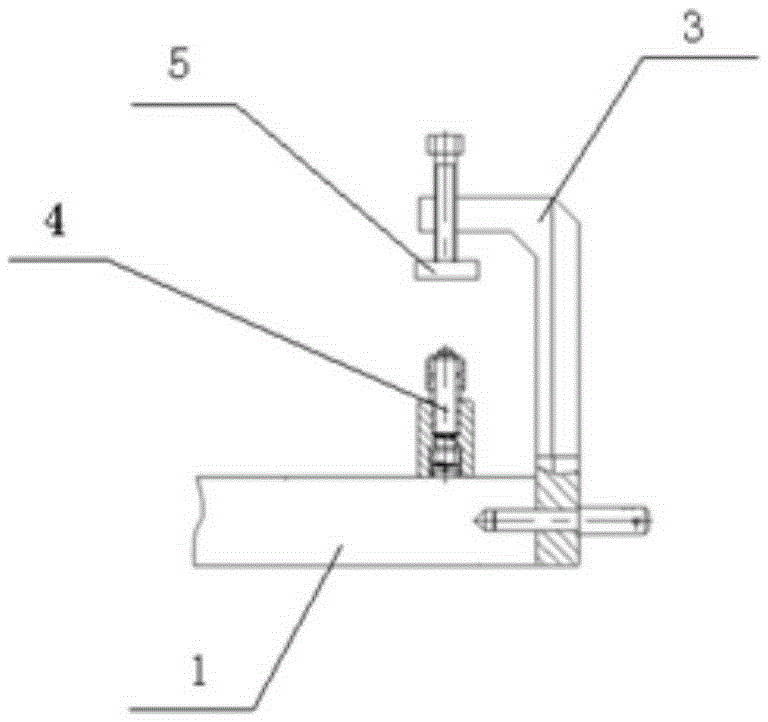

[0018] 2. The manufacture of machining fixtures: the fixture includes a disc 1, a top block 2, a positioning pin 4 and a pressing card 3; the top block 2 is arranged on the disc 1 for supporting the The positioning surface 6; the positioning pin 4 is arranged on the disc 1 for positioning the positioning hole 7; the pressing card 3 is installed on the outer edge of the disc 1, and a pressing Block 5, used to compress the casing casting;

[0019] 3. Process the casing casting: install the fixture on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com