Flexible flat connecting wire slitting system and its control method

A technology of flexible flat and connecting wires, applied in metal processing and other directions, can solve the problems of low production efficiency, fixed, inconvenient use, etc., and achieve the effects of good versatility, small dimensional error, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

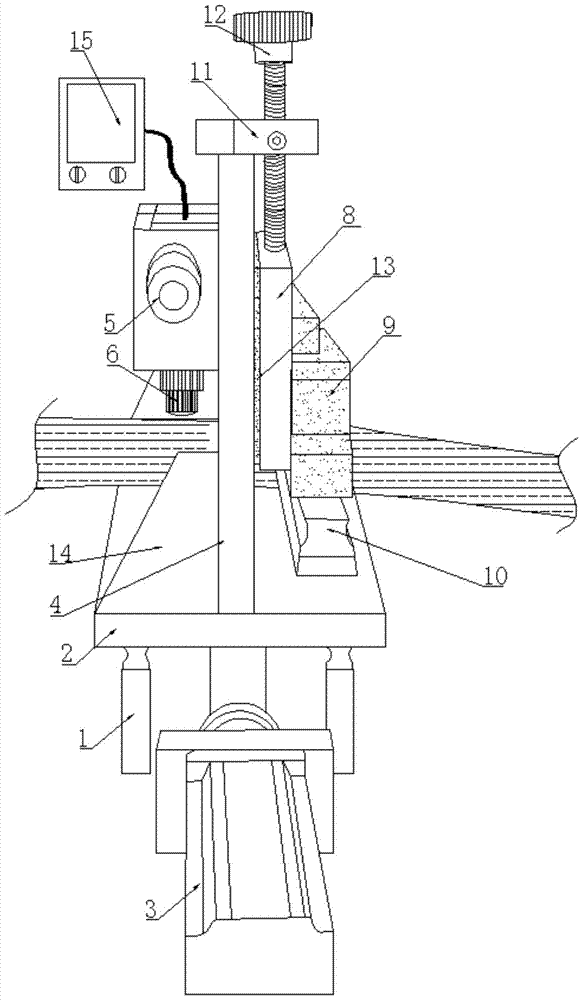

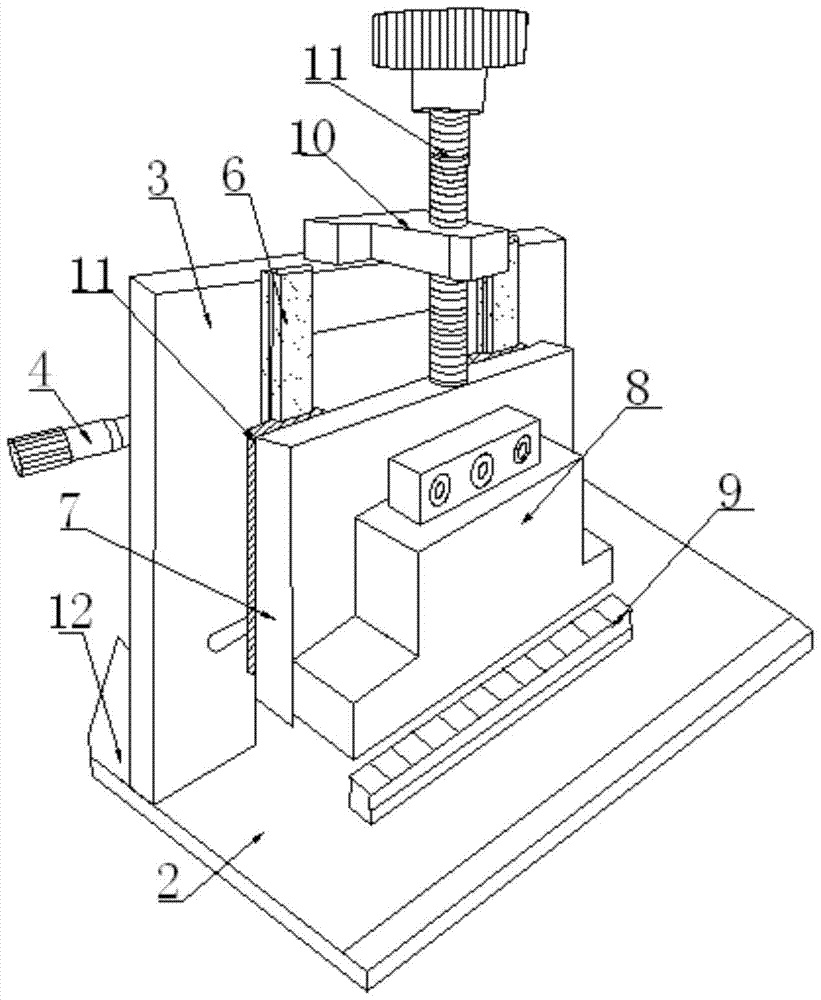

[0032] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

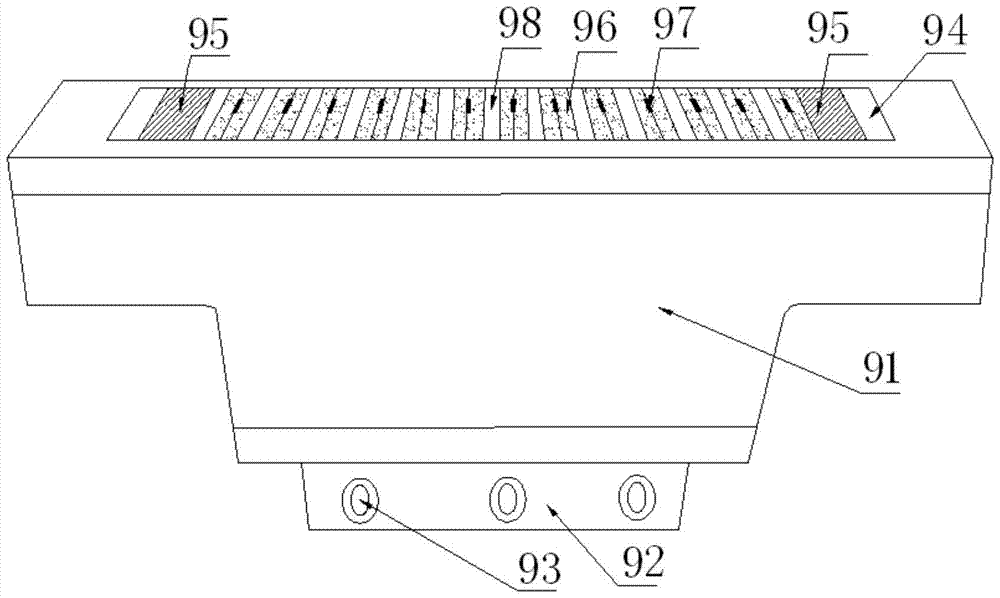

[0033] Such as Figure 1 ~ Figure 2 As shown, a flexible flat connecting line slitting system includes two first slide rails 1, on which a base plate 2 is supported, the bottom surface of the base plate 2 is fixedly connected to the output shaft of a servo motor 3, And the servo motor 3 is arranged facing the opening end of the first slide rail 1, a mounting plate 4 is vertically fixed on the bottom plate 2, and a reinforcement is also provided at the connection between the bottom plate 2 and the mounting plate 4. plate 14, a camera 6 is fixed on one side of the mounting plate 4 through a lateral displacement adjustment mechanism 5, the installation direction of the camera 6 is perpendicular to the plane where the base plate 2 is located, and a camera 6 is fixed on the other side of the mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com