Wheel disc type particle damping shock absorber for rail vehicles

A rail vehicle and particle damping technology, which is applied in the field of rail vehicle vibration reduction, can solve the problems of wide vibration frequency of rigid wheels, increased wear of wheel sets, long service life, etc., and achieve the effects of reducing noise and wear, reducing noise, and increasing the probability of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

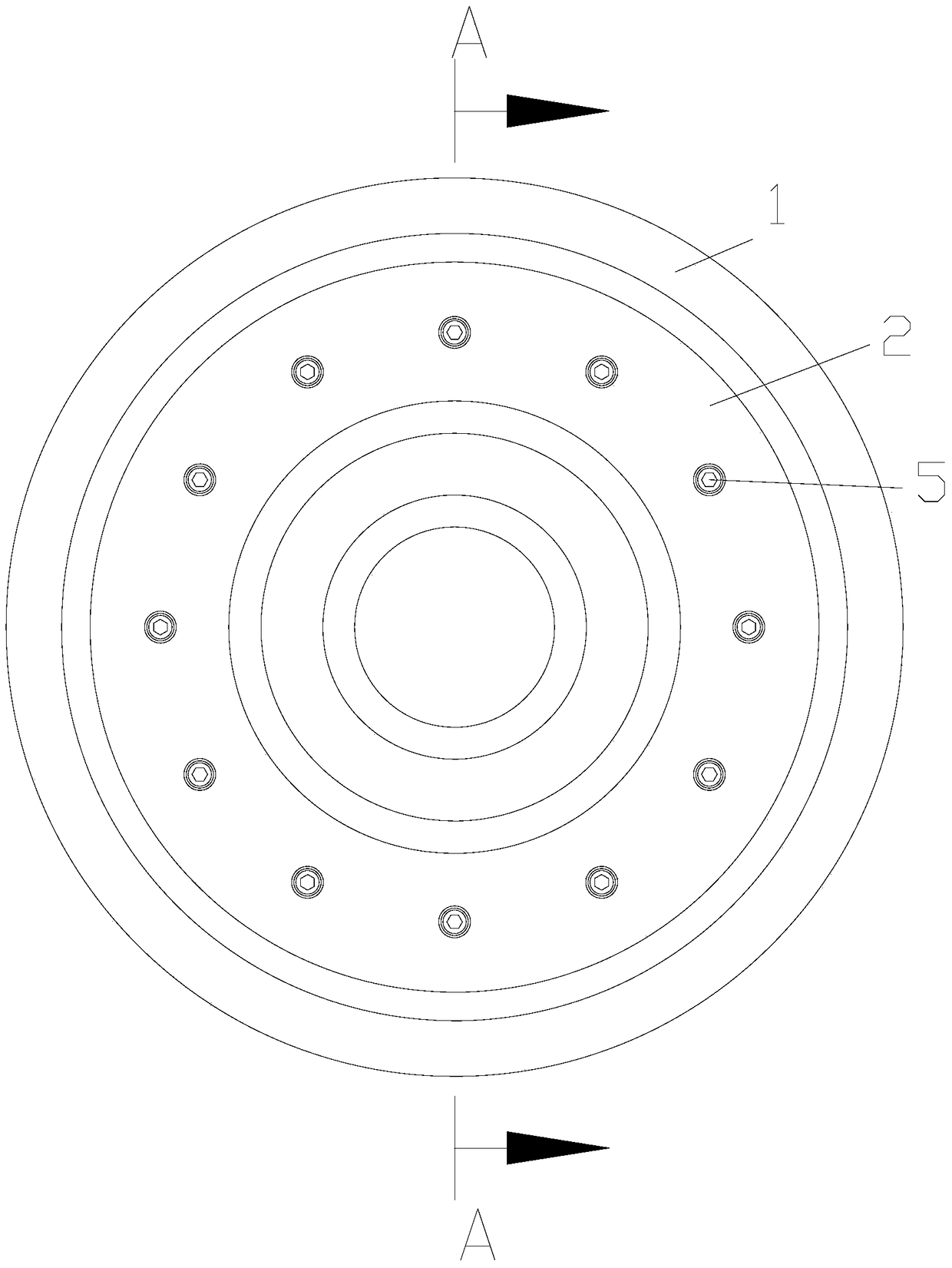

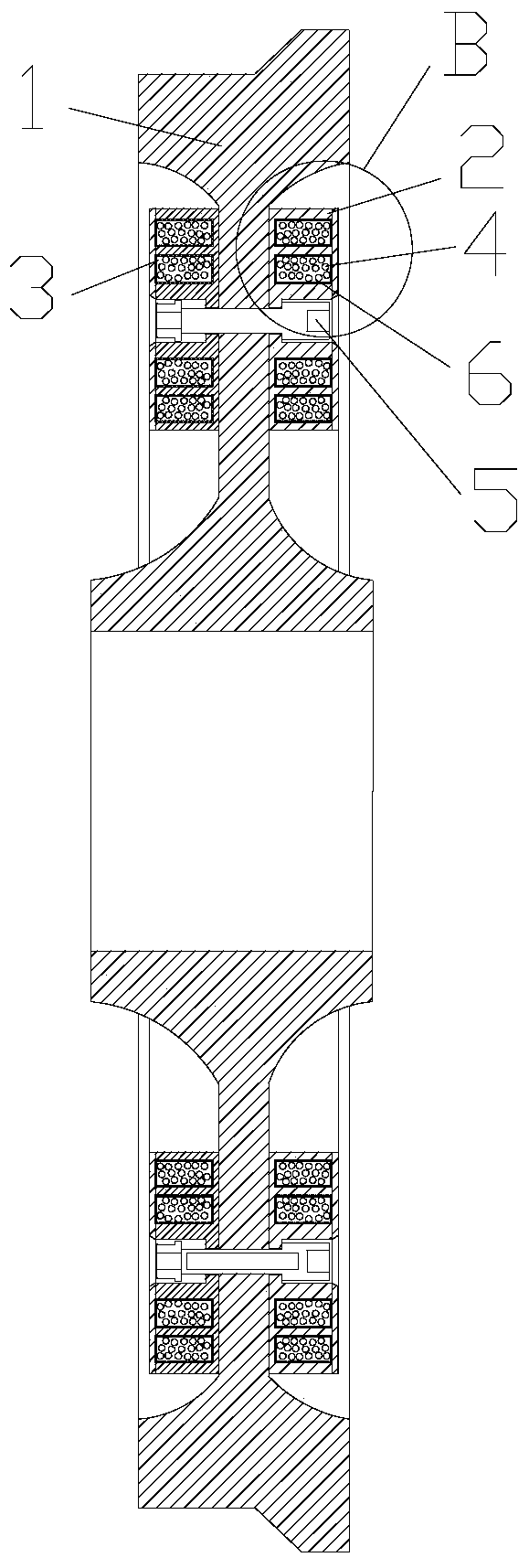

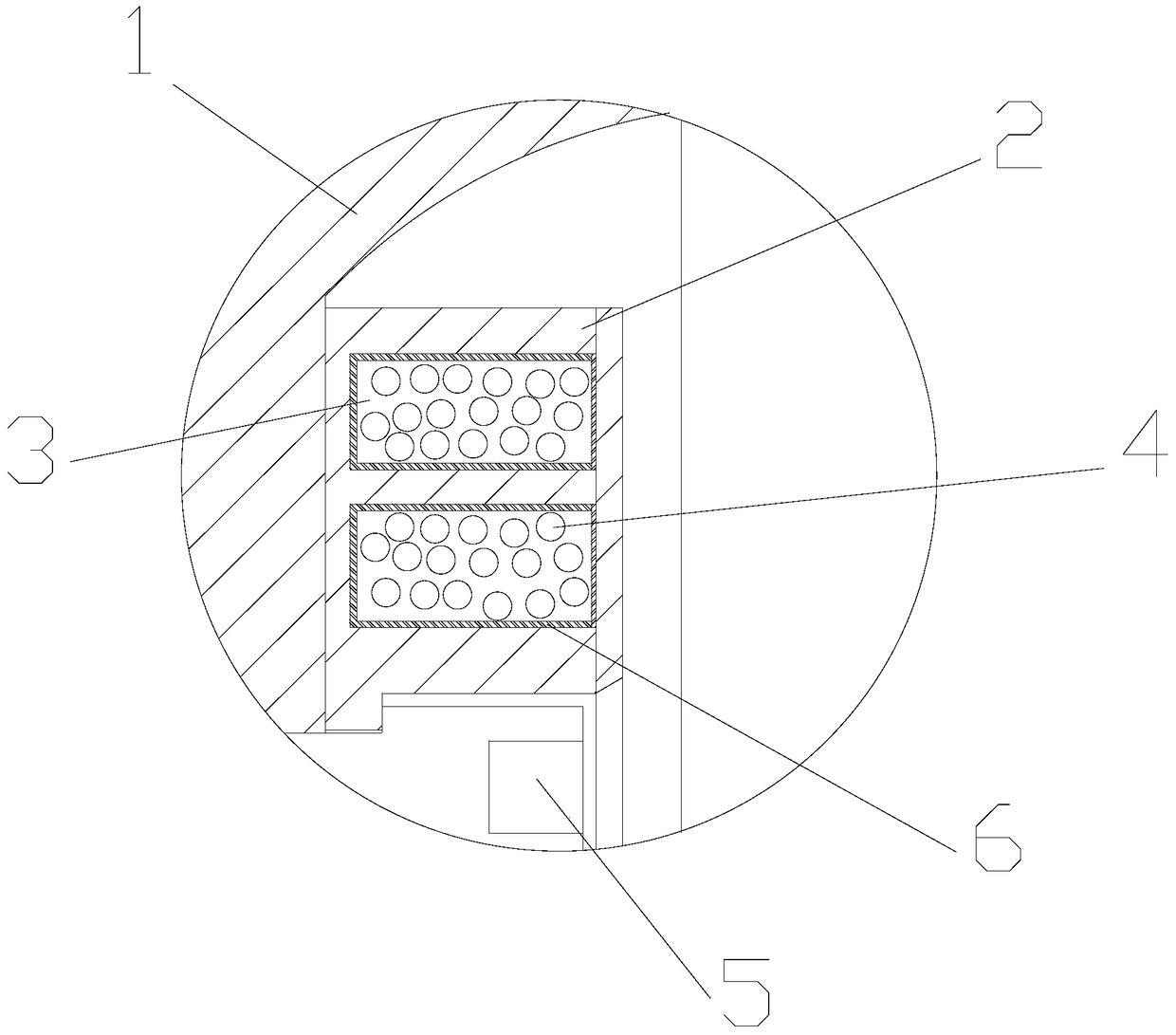

[0030] In order to solve the problems of reduced service life of the rigid wheel 1 and ride comfort caused by noise and high-frequency vibration caused by the rolling of the tire, the present invention uses particle damping technology to study and analyze the wheel 1, and proposes a wheel disc type for rail vehicles. Particle damping shock absorbers such as figure 1 with figure 2 As shown, the shock absorber includes:

[0031] The disc housing 2 is made of composite damping steel plate, and is provided with a plurality of concentric annular sealing grooves 3. The number of annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com