Hand-pushed-forklift carrying tray

A technology of carrying pallets and hand forks, which is applied in the direction of trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problems of inconvenient transportation, no storage plane, easy friction damage, etc., and can make up for insufficient protection, easy disassembly, easy carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

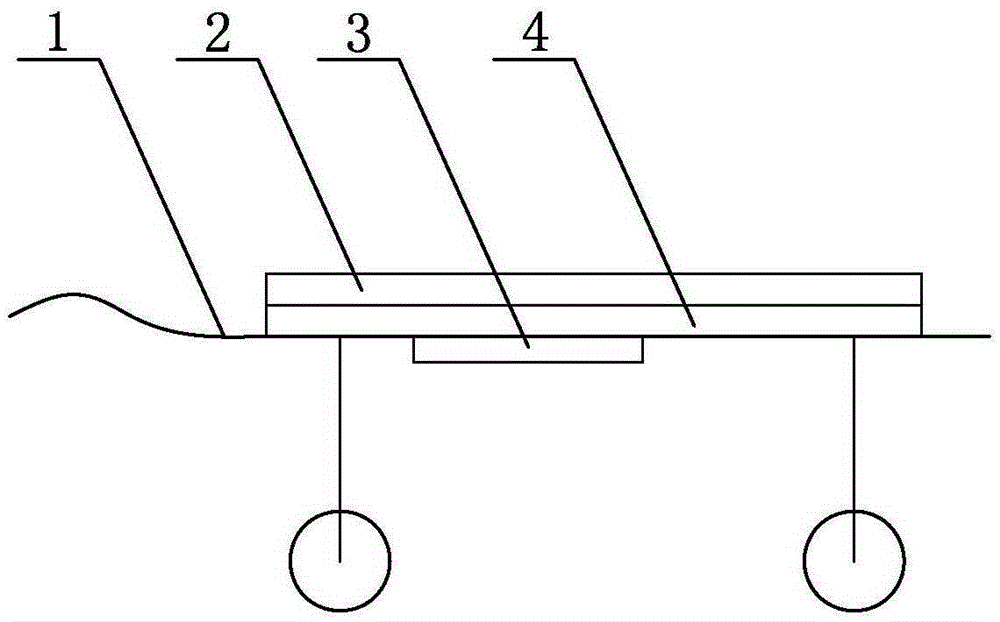

[0012] Such as figure 1 As shown, the hand-push forklift load tray includes a trolley body 1, a sponge layer 3 is provided on the trolley body 1, a rubber layer 2 is provided on the sponge layer 3, and patterns are provided on the rubber layer 2.

[0013] The dolly body 1 is equipped with an air bubble level regulating device 4 .

[0014] The body of the trolley is provided with a sponge layer and a rubber layer. When in use, the cargo is damped and fixed due to its own weight causing the sponge to sag. The upper rubber layer uses patterns to increase friction and reduce cargo movement during transportation. The air bubble level adjustment device is used. , by adjusting the inclination to reduce the impact on the movement of the goods when going up and downhill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com