Container with sliding device

A sliding device and container technology, which is applied in the directions of packaging, transportation, packaging, containers, etc., can solve the problems of high labor intensity of construction workers, single functionality of containers, unfavorable high-efficiency utilization, etc., to increase the variety and quantity, expand the scope of application, The effect of reducing the waste of material and human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

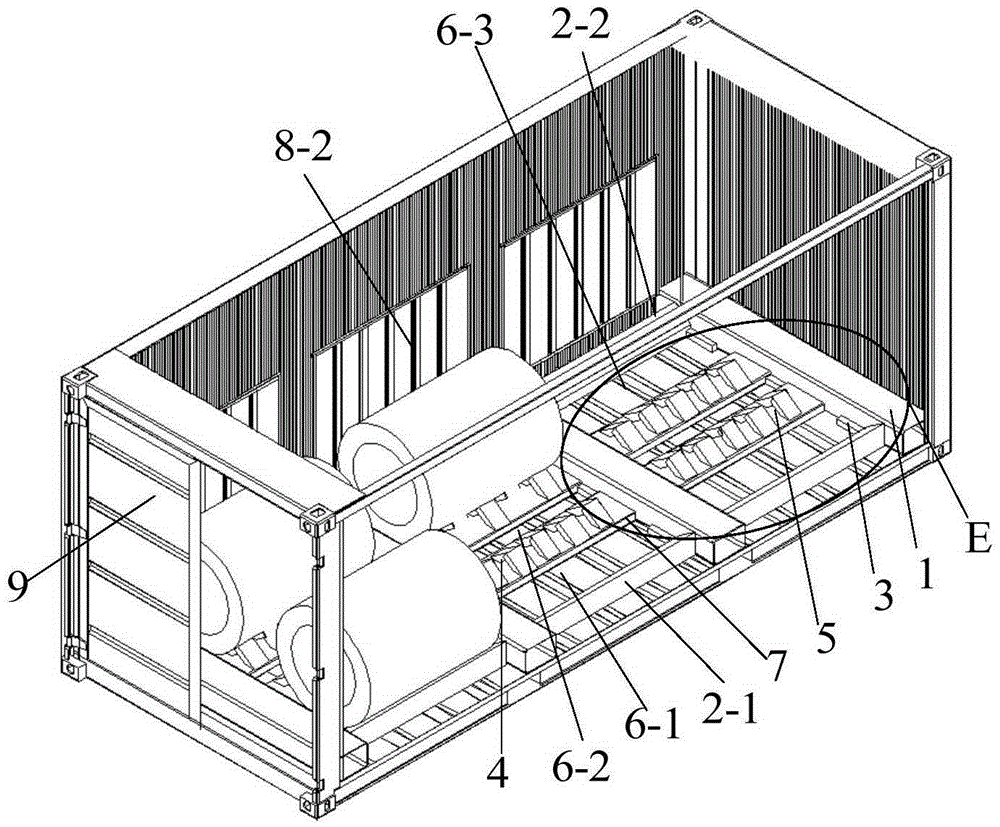

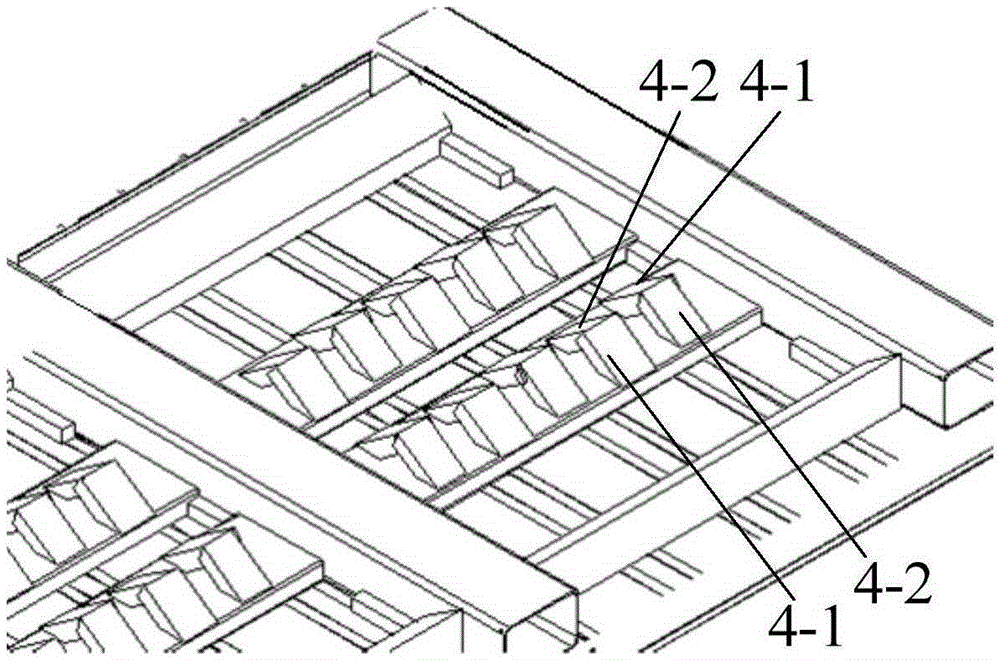

[0026] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a container with a sliding device. The container with a sliding device includes a box body and an underframe arranged in the box body. The box body includes a top plate, a front side plate, and a rear side plate. , a six-sided box composed of a left side plate, a right side plate and an underframe. Right-angled trapezoidal block 2-2 and at least two retaining pipes 1, the quantity of retaining pipes 1 can be set correspondingly according to the quantity, type and size of the goods to be transported, if the quantity of retaining pipes 1 is 2, they are respectively arranged in At the left side panel and the right side panel of the box body, the first right-angle trapezoidal block 2-1 and the second right-angle trapezoidal block 2-2 are respectively connected with the retaining pipe 1 to form a channel for placing goods, that is, the first right-angle trapezoidal block 2-1. The second...

Embodiment 2

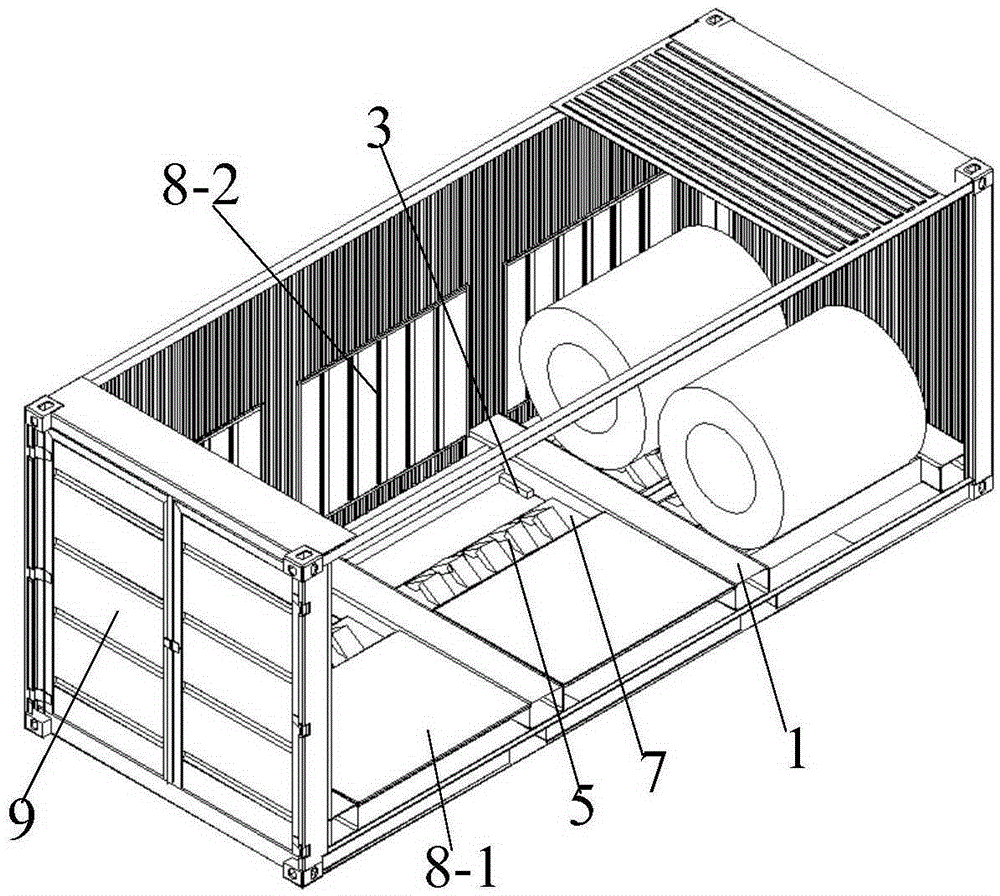

[0040] The container with the sliding device provided by the present invention can also be used to load dry bulk goods, such as Figure 4 to Figure 5 As shown, the box body is a six-sided box body composed of a top plate, a front side plate, a rear side plate, a left side plate, a right side plate and an underframe, and an end door 9 is arranged on the left side plate or the right side plate, and the top plate is Soft top that opens longitudinally or transversely. In this embodiment, when shipping dry bulk cargo, the dry bulk cargo is corn or soybeans or other bulk cargo types, the double-fold bottom plate is placed flat on the through groove and fixed on the retaining pipe 1 by the latch limit, and the box is opened. The top plate of the dry bulk cargo is loaded into the dry bulk cargo. When the dry bulk cargo is transported to the destination, the dry bulk cargo is poured out through the end door 9, thus realizing the operation process of transporting the dry bulk cargo. Oth...

Embodiment 3

[0042] The container with the sliding device provided by the present invention can also be used to load dry bulk cargo. In this embodiment, when loading dry bulk cargo, the dry bulk cargo is corn or soybean or other bulk cargo types. The through slot is fixed on the retaining pipe 1 through the pin limit, the top plate on the box is opened, and the dry bulk cargo is loaded. When the dry bulk cargo is transported to the destination, the dry bulk cargo is poured out through the end door 9, and the dry bulk cargo is poured out by the This realizes the operation process of transporting dry bulk cargo, and other technical solutions are the same as those in Embodiment 1. To avoid redundant description, no additional elaboration is made here.

[0043] In summary, a container with a sliding device provided by the present invention includes a box body and an underframe arranged in the box body. The underframe includes an inverted V-shaped group frame, a first right-angled trapezoid bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com