Two-stage mixing process for magnesium phosphate cement-based materials

A magnesium phosphate cement and mixing process technology, which is applied in the field of civil engineering materials processing, can solve the problems of development and research that have not been reported yet, and achieve the effects of promoting the acid-base reaction process, reducing movement resistance, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

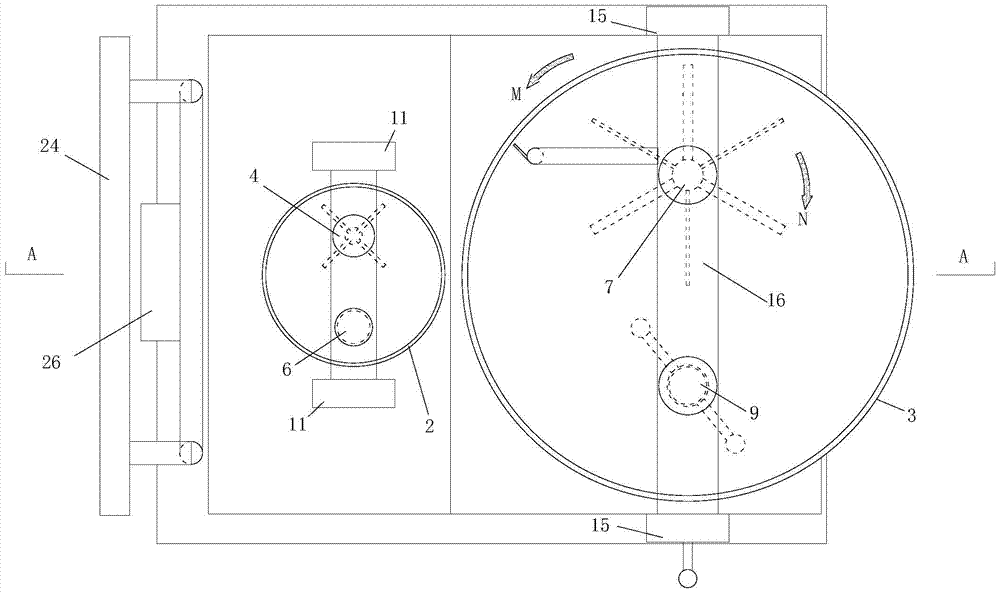

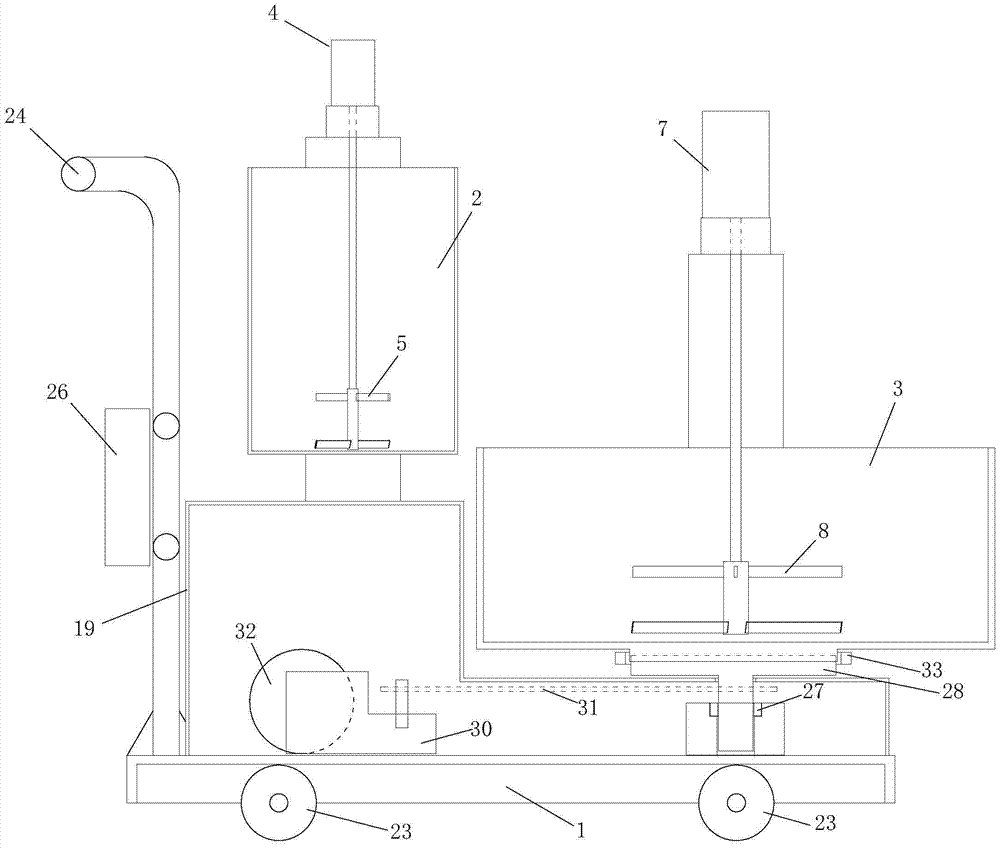

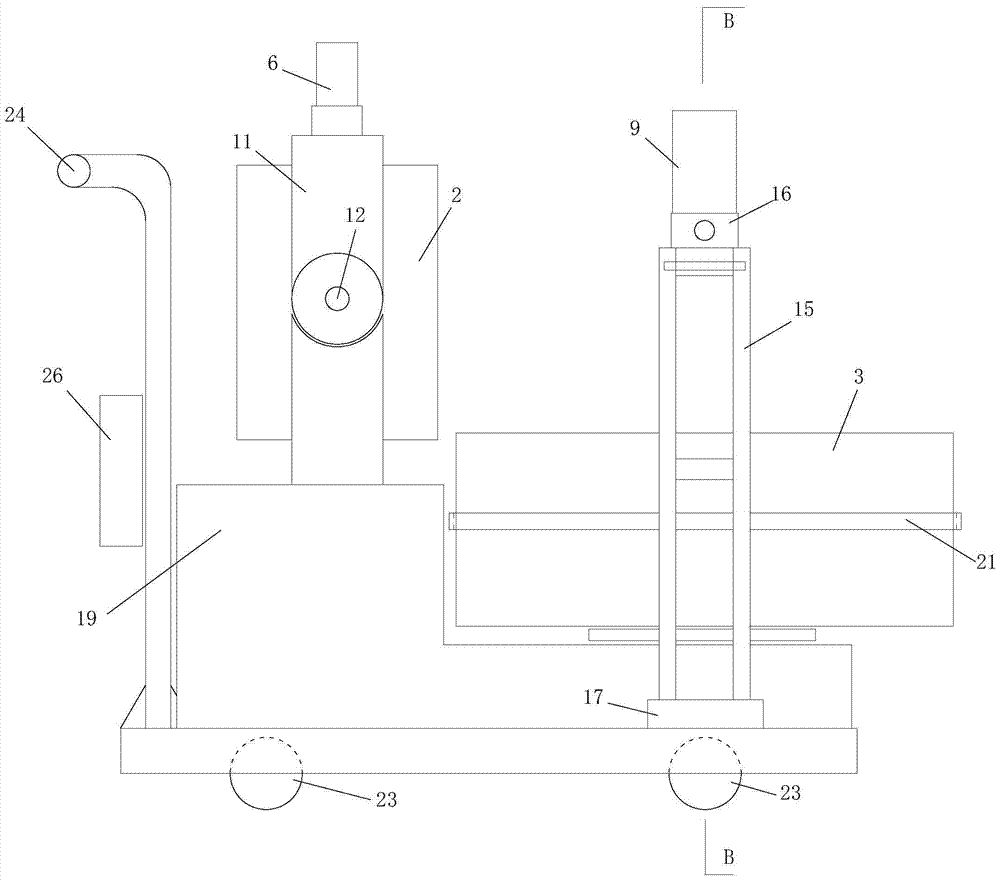

Image

Examples

Embodiment Construction

[0033] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to the conditions of the specific construction unit, and the unspecified implementation conditions are usually the conditions in routine experiments.

[0034] Embodiment of the technical solution:

[0035] Magnesium phosphate cement-based materials are generally divided into magnesium phosphate cement slurry, magnesium phosphate cement mortar, magnesium phosphate cement concrete, and fiber magnesium phosphate cement-based composite materials. The applicant has verified by experiments that the feasible order of stirring and feeding is: (a) the retarder component dissolves (water and composite retarder); (b) adds the acid component of the magnesium phosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com