Preparation method of metal organic framework derived iron sulfide and carbon nano composite material

A metal-organic framework and composite material technology, which is applied in the field of metal-organic framework-derived iron sulfide@carbon nanocomposite preparation, can solve the problems of restricting the application of new energy storage fields, prone to agglomeration, and not taken into account, and achieves increased reversible intercalation. Uniform distribution of sites and products without agglomeration, and the effect of improving charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a metal-organic framework-derived iron sulfide@carbon nanocomposite material, comprising the following steps:

[0029] Step 1, preparation of iron-based metal-organic framework materials:

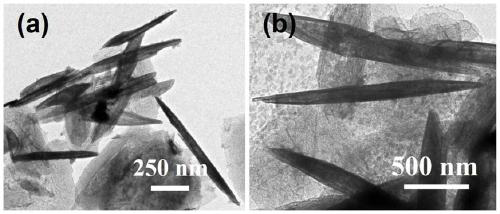

[0030] Weigh 1.114g of ferric nitrate and 3.860g of fumaric acid and dissolve them in 80mL of ultrapure water, stir evenly for 20min to obtain an orange transparent mixed solution; then place the mixed solution in a Teflon-lined Carry out hydrothermal reaction at 150°C in a hydrothermal reaction kettle, keep warm for 3 hours, cool to room temperature, then centrifuge at a speed of 8000r / min for 2 minutes, wash with ultrapure water and absolute ethanol for 3 times, and finally cool at 70°C Carry out vacuum drying 10h, obtain the MIL-88 nanoparticle that the average particle size is 750nm spindle shape;

[0031] Step 2, preparation of iron sulfide@carbon nanocomposites:

[0032] Mix the MIL-88 nanoparticles and thiourea obtained in step 1 with a mass ratio of 1...

Embodiment 2

[0035] A method for preparing a metal-organic framework-derived iron sulfide@carbon nanocomposite material, comprising the following steps:

[0036] Step 1, preparation of iron-based metal-organic framework materials:

[0037] Weigh 0.279g of ferric nitrate and 0.968g of fumaric acid and dissolve them in 50mL of ultrapure water, stir evenly for 30min to obtain an orange transparent mixed solution; then place the mixed solution in a Teflon-lined Carry out hydrothermal reaction at 120°C in a hydrothermal reaction kettle, keep warm for 4 hours, cool to room temperature, then centrifuge at a speed of 5000r / min for 5 minutes, then wash with ultrapure water and absolute ethanol for 3 times, and finally cool at 70°C Carry out vacuum drying for 12h to obtain MIL-88 nanoparticles with an average particle size of 750nm spindle shape;

[0038] Step 2, preparation of iron sulfide@carbon nanocomposites:

[0039] MIL-88 nanoparticles and thiourea were mixed according to a mass ratio of 1:...

Embodiment 3

[0042] A method for preparing a metal-organic framework-derived iron sulfide@carbon nanocomposite material, comprising the following steps:

[0043] Step 1, preparation of iron-based metal-organic framework materials:

[0044] Weigh 0.692g of ferric nitrate and 2.414g of fumaric acid and dissolve them in 60mL of ultrapure water, stir evenly for 25min to obtain an orange transparent mixed solution; then place the mixed solution in a Teflon-lined Carry out hydrothermal reaction at 1130°C in a hydrothermal reaction kettle, keep warm for 3 hours, cool to room temperature, then centrifuge at a speed of 7500r / min for 3 minutes, then wash with ultrapure water and absolute ethanol for 3 times, and finally cool at 80°C Carry out vacuum drying 10h, obtain the MIL-88 nanoparticle that the average particle size is 750nm spindle shape;

[0045] Step 2, preparation of iron sulfide@carbon nanocomposites:

[0046] Mix the MIL-88 nanoparticles and thiourea obtained in step 1 with a mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com