Lithium metallic oxide precursor material with annual ring type structure, anode material prepared by lithium metallic oxide precursor material, and preparation method and application

A lithium metal oxide, cathode material technology, applied in the direction of positive electrodes, structural parts, active material electrodes, etc., can solve the problems of poor rate performance, increased production and preparation costs, low volume specific energy, etc., to improve discharge capacity and Rate performance, improved cycle stability, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

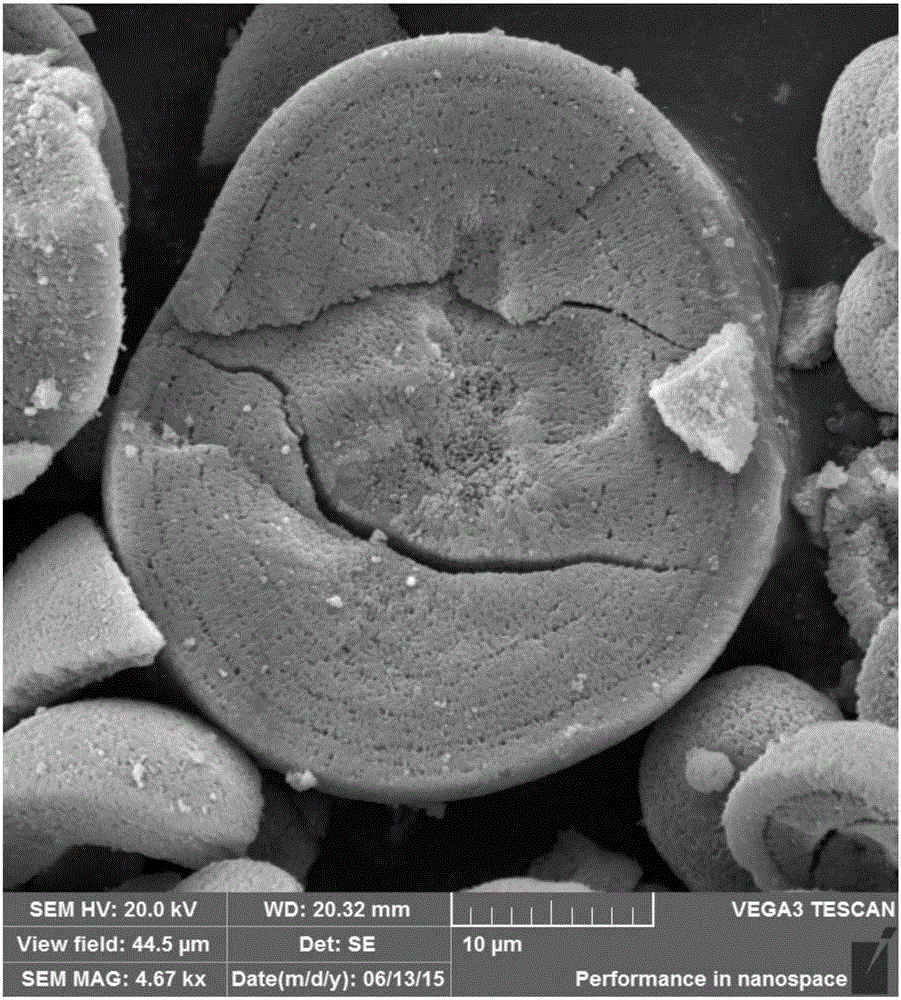

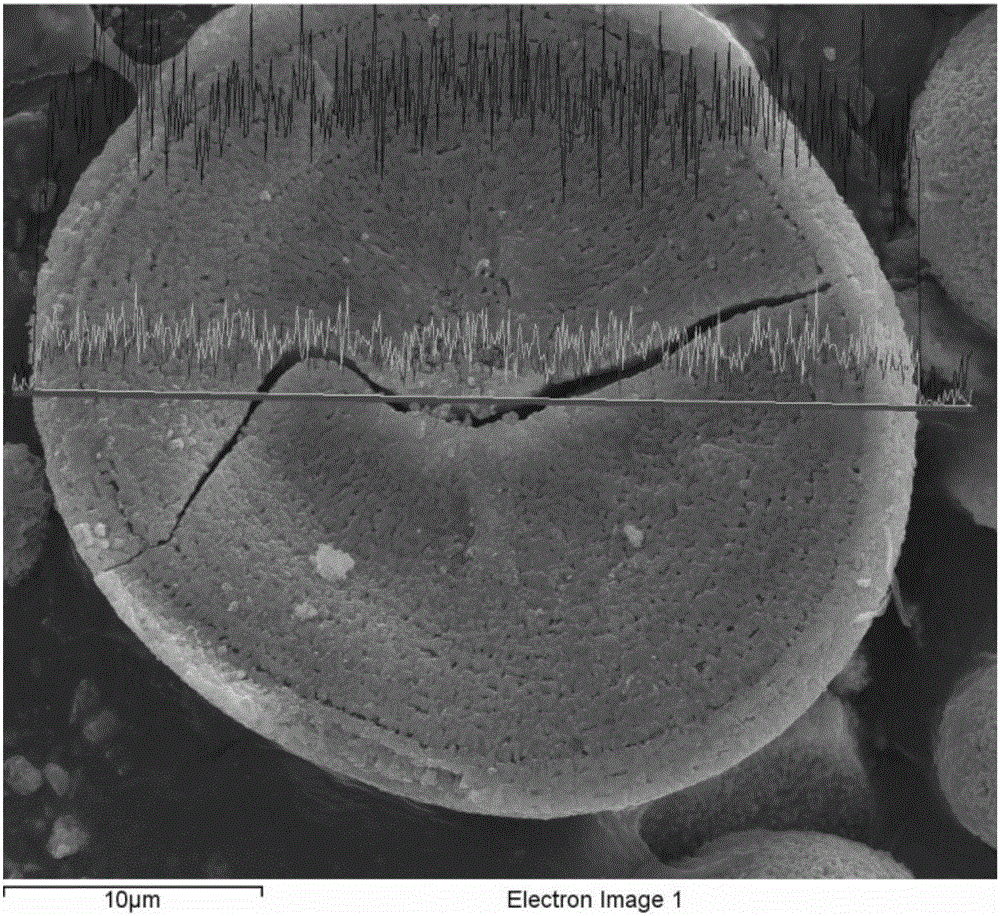

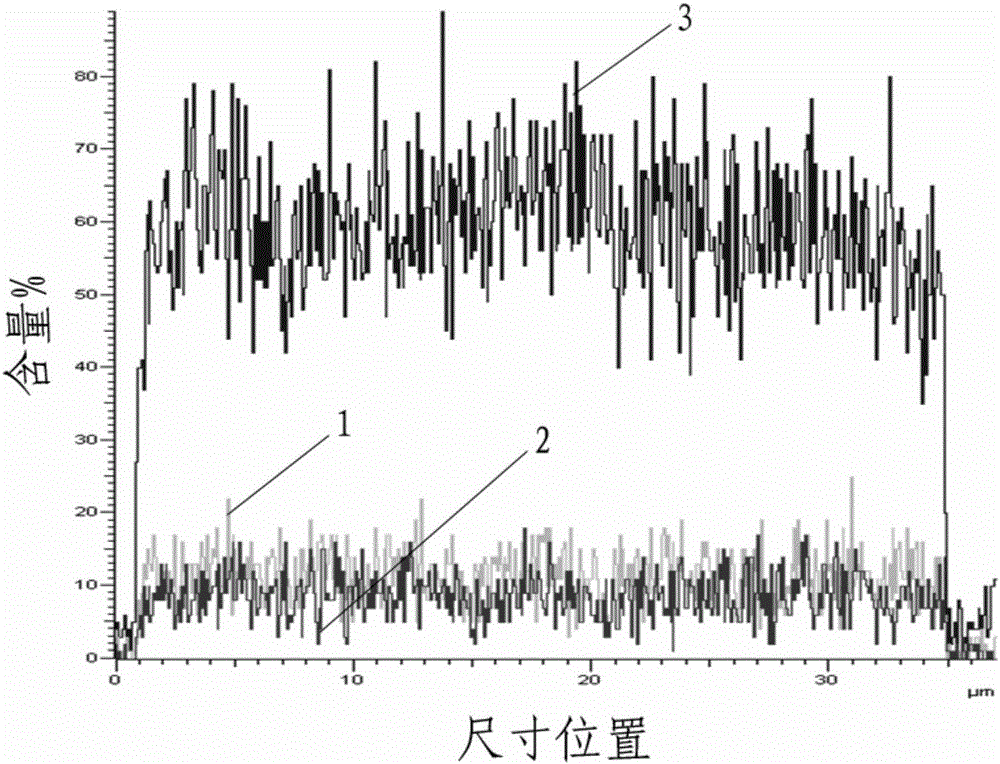

[0042] Embodiment 1: The lithium metal oxide precursor material with "annual ring" structure of the present invention is spherical secondary particles formed by agglomeration of primary particles, and the primary particles in the secondary particles are in the form of "annual rings" Formula arrangement, the chemical formula of the primary particle is Ni x co y mn z m 1-x-y-z (OH) 2 or Ni x co y mn z m 1-x-y-z CO 3 , where 0≤x≤1, 0≤y≤1, 0≤z≤1, x+y+z≤1, M is Zr, Fe, Sm, Pr, Nb, Ga, Zn, Y, Mg, Al, One or more of Cr, Ca, Na, Ti, Cu, K, Sr, Mo, Ba, Ce, Sn, Sb, La, Bi.

specific Embodiment approach 2

[0043] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the average particle size of the secondary particles is 1 μm to 40 μm, and the tap density is 1 g / cm 3 ~4g / cm 3 . Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: The preparation method of the lithium metal oxide precursor material with the "annual ring" structure of this embodiment, the lithium metal oxide precursor material is prepared according to the following steps:

[0045] 1. According to the chemical formula Ni x co y mn z m 1-x-y-z (OH) 2 or Ni x co y mn z m 1-x-y-z CO 3 , where 0≤x≤1, 0≤y≤1, 0≤z≤1, x+y+z≤1, nickel salt and cobalt salt are weighed according to the stoichiometric ratio of nickel, cobalt, manganese and M metal elements , manganese salt and M salt, nickel salt, cobalt salt, manganese salt and M salt are dissolved in water to form a mixed metal salt solution a1 with a concentration of 0.1mol / L to 10mol / L; wherein M is Zr, Fe, Sm, One or more of Pr, Nb, Ga, Zn, Y, Mg, Al, Cr, Ca, Na, Ti, Cu, K, Sr, Mo, Ba, Ce, Sn, Sb, La, Bi;

[0046] 2. Separately configure a precipitant aqueous solution b1 with a concentration of 0.1mol / L-10mol / L and a complexing agent aqueous solution c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com