Method for extracting ganoderma polysaccharide from ganoderma lucidum fruiting body

A technology of Ganoderma lucidum fruiting body and Ganoderma lucidum polysaccharide is applied in the field of extracting Ganoderma lucidum polysaccharide from Ganoderma lucidum fruiting body, which can solve the problems of environmental pollution, high degree of lignification and high temperature, and achieve the effects of improving extraction efficiency, simple operation and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

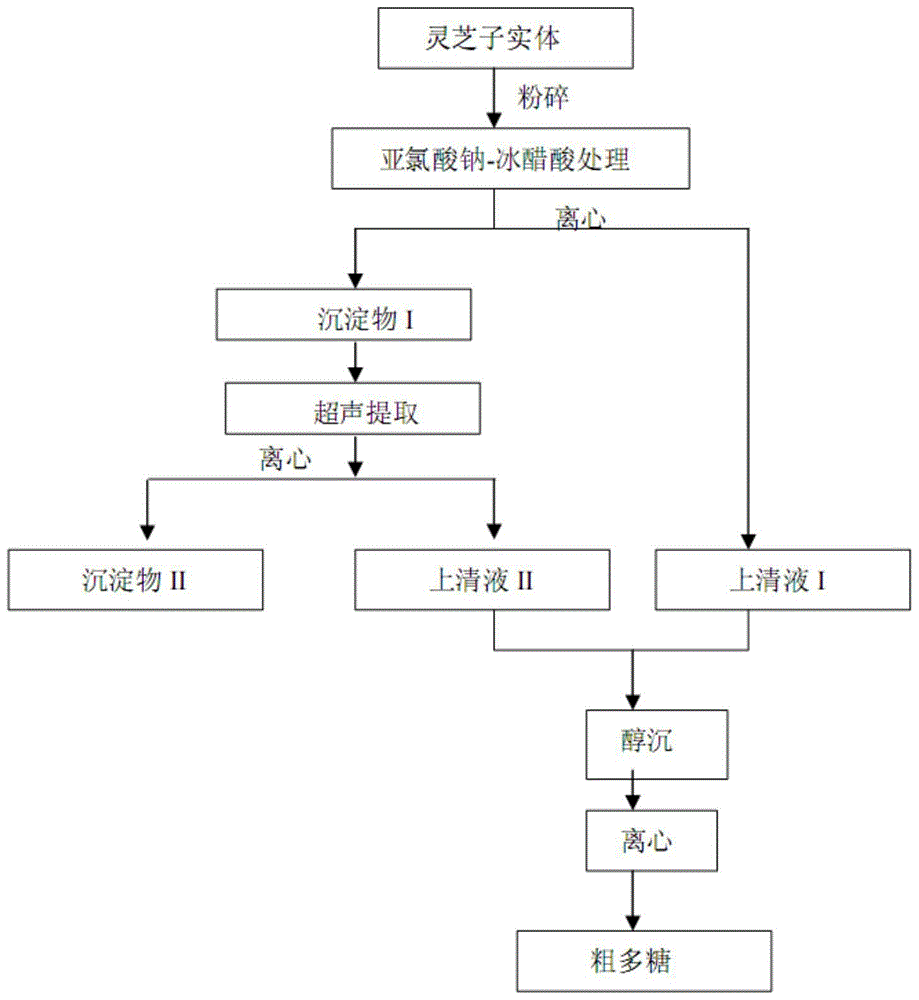

[0028] The method for extracting Ganoderma lucidum polysaccharide from Ganoderma lucidum fruiting body, such as figure 1 shown, including the following steps,

[0029] A. Raw material pretreatment: after drying and crushing the fruiting bodies of Ganoderma lucidum, mix the crushed fruiting bodies of Ganoderma lucidum with water to form a mixed solution, and the weight ratio of fruiting bodies of Ganoderma lucidum to water is 1:20;

[0030] B. Sodium chlorite-glacial acetic acid treatment: put the mixed solution in a water bath at 60°C, add sodium chlorite accounting for 40% of the dry weight of Ganoderma lucidum, and after stirring, add 40% of the dry weight of Ganoderma lucidum dropwise every 1 hour glacial acetic acid, stir after dripping glacial acetic acid, drip glacial acetic acid three times according to the above method, and stir after each dripping glacial acetic acid;

[0031] Put it in a shaker and oscillate, then centrifuge to obtain supernatant I and precipitate I...

Embodiment 2

[0040] The method for extracting Ganoderma lucidum polysaccharide from Ganoderma lucidum fruiting body, such as figure 1 shown, including the following steps,

[0041] A. Raw material pretreatment: after drying and crushing the fruiting bodies of Ganoderma lucidum, mixing the crushed fruiting bodies of Ganoderma lucidum with water to form a mixed solution, the weight ratio of fruiting bodies of Ganoderma lucidum to water is 1:30;

[0042] B. Sodium chlorite-glacial acetic acid treatment: put the mixed solution in a water bath at 80°C, add sodium chlorite accounting for 40% of the dry weight of Ganoderma lucidum, and after stirring, add 60% of the dry weight of Ganoderma lucidum dropwise every 1 hour glacial acetic acid, stir after dripping glacial acetic acid, drip glacial acetic acid three times according to the above method, and stir after each dripping glacial acetic acid;

[0043] Put it in a shaker and oscillate, then centrifuge to obtain supernatant I and precipitate I;...

Embodiment 3

[0051] The method for extracting Ganoderma lucidum polysaccharide from Ganoderma lucidum fruiting body, such as figure 1 shown, including the following steps,

[0052] A. Raw material pretreatment: after drying and crushing the fruiting bodies of Ganoderma lucidum, mix the crushed fruiting bodies of Ganoderma lucidum with water to form a mixed solution, and the weight ratio of fruiting bodies of Ganoderma lucidum to water is 1:25;

[0053] B. Sodium chlorite-glacial acetic acid treatment: put the mixed solution in a water bath at 65°C, add sodium chlorite accounting for 40% of the dry weight of Ganoderma lucidum, and after stirring, add 45% of the dry weight of Ganoderma lucidum dropwise every 1 hour glacial acetic acid, stir after dripping glacial acetic acid, drip glacial acetic acid three times according to the above method, and stir after each dripping glacial acetic acid;

[0054] Put it in a shaker and oscillate, then centrifuge to obtain supernatant I and precipitate I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com