Composite filaments of dacron positive ion dyeable filaments and common dacron filaments

A polyester filament, composite filament technology, applied in textiles, papermaking, yarn and other directions, can solve the problem of high weaving cost of multi-color interwoven yarn, and achieve the effect of reducing weaving cost, natural color effect and gorgeous and gorgeous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

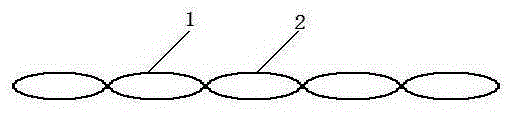

[0010] Example: Feed a strand of ordinary polyester filament 2 into the first roller of the texturing machine, after thermal stretching, false twist deformation, and setting, another strand of polyester cationic dyeable filament 1 is fed from the false twist deformation texturing machine 0 After being fed by the roller and deformed by the false twist of the yarn guide, the two strands of yarn are plied before the third roller of the texturing machine and enter the nozzle for interlacing and compounding to form a composite filament, which can not only replace the yarn interlaced by multiple yarns of different colors, While reducing the weaving cost, the color effect is more natural and colorful due to the color difference formed by the difference in color absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com