Water jet cutting device for repairing craters in airport runway

A cutting device and water jet technology, applied in the field of mechanical devices, can solve the problems of long time, high cutting noise, and inability to guarantee the straightness of the cutting machine, and achieve the effect of low cost, no dust and noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

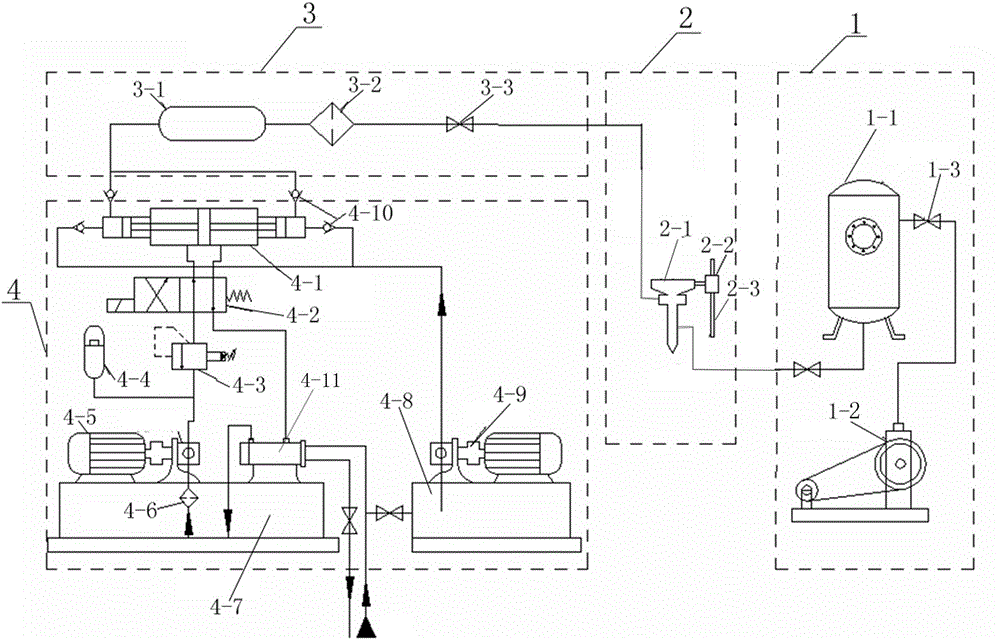

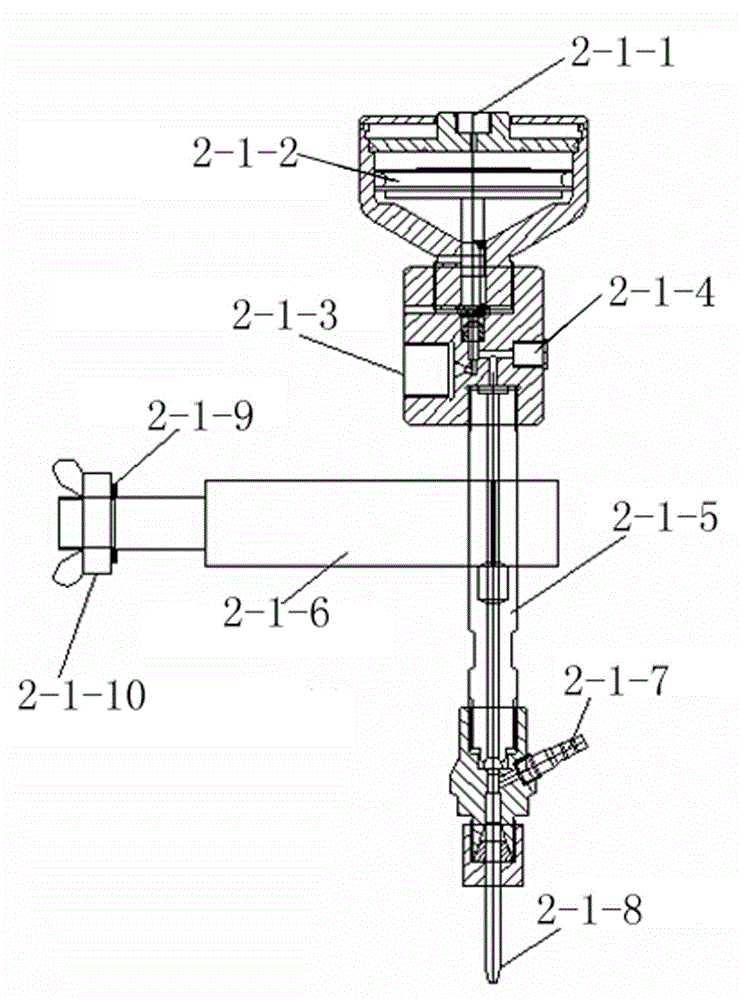

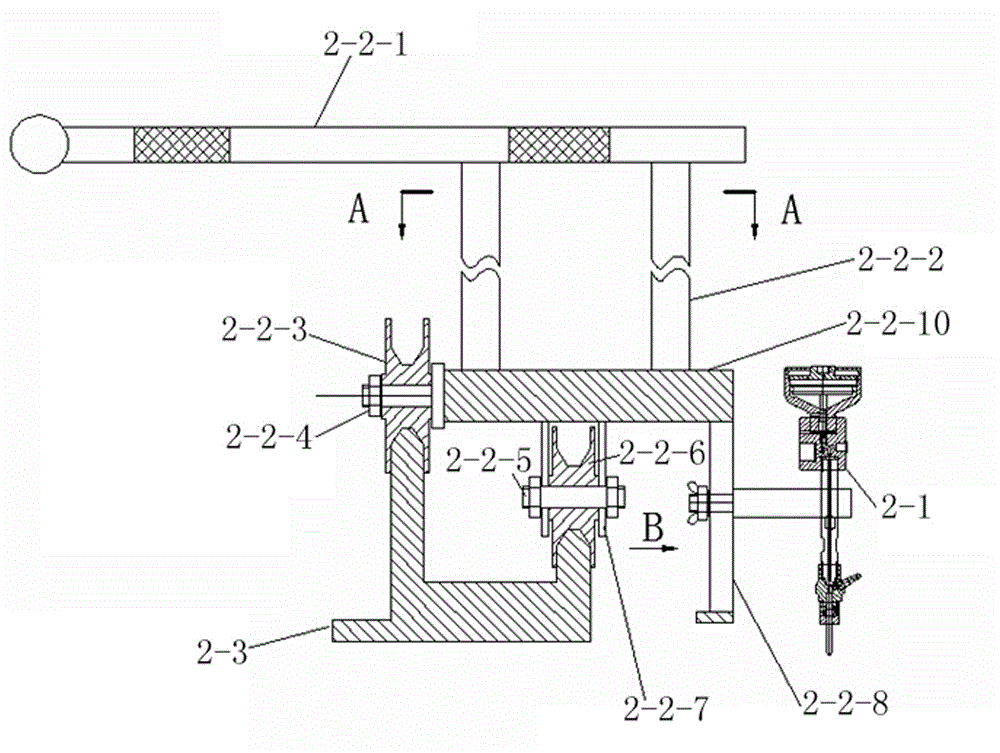

[0038] refer to Figure 1-5 , a water jet cutting device for repairing airport runway craters, which includes a cutting system 2 provided with a high-pressure water nozzle 2-1, a sand supply system 1 provided with a sand storage tank 1-1, and a reciprocating pressurized The supercharging system 4 of the device 4-1 and the auxiliary system 3 provided with the water accumulator 3-1; the two ends of the reciprocating supercharger 4-1 of the supercharging system 4 are connected to the auxiliary system 3 through pipelines One end of the water accumulator 3-1, the other end of the water accumulator 3-1 is connected with the high-pressure water inlet 2-1-3 of the high-pressure water nozzle 2-1 through a pipeline, and the sand storage of the sand supply system 1 The tank 1-1 is connected with the sand inlet 2-1-7 of the high-pressure water nozzle 2-1 through a pipeline.

[0039] refer to Figure 1-5 , the cutting system 2 also includes a high-pressure water nozzle 2-1, a guide frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com