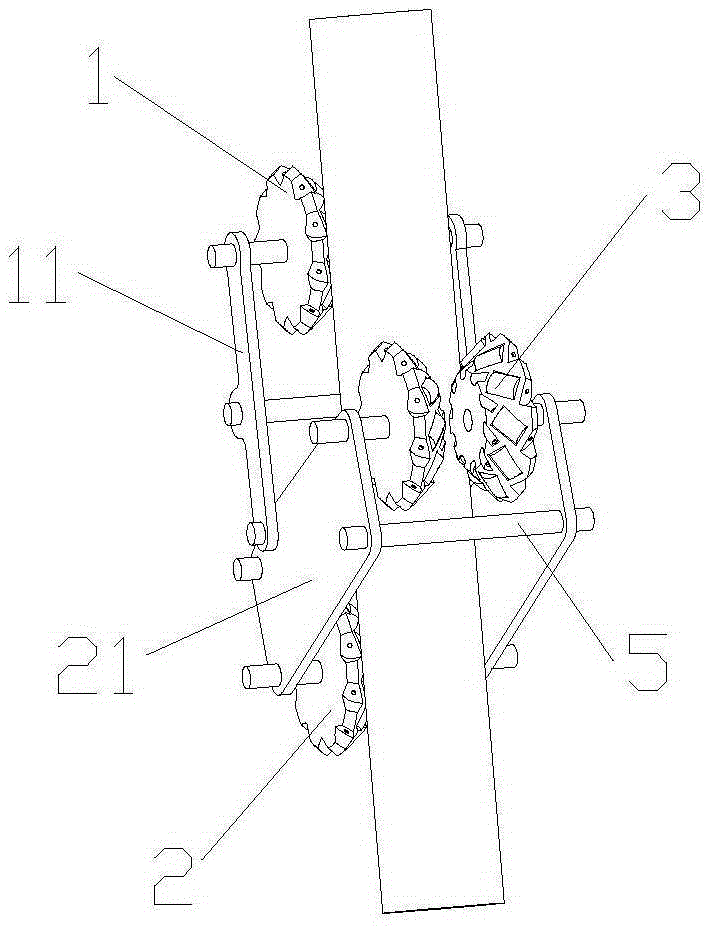

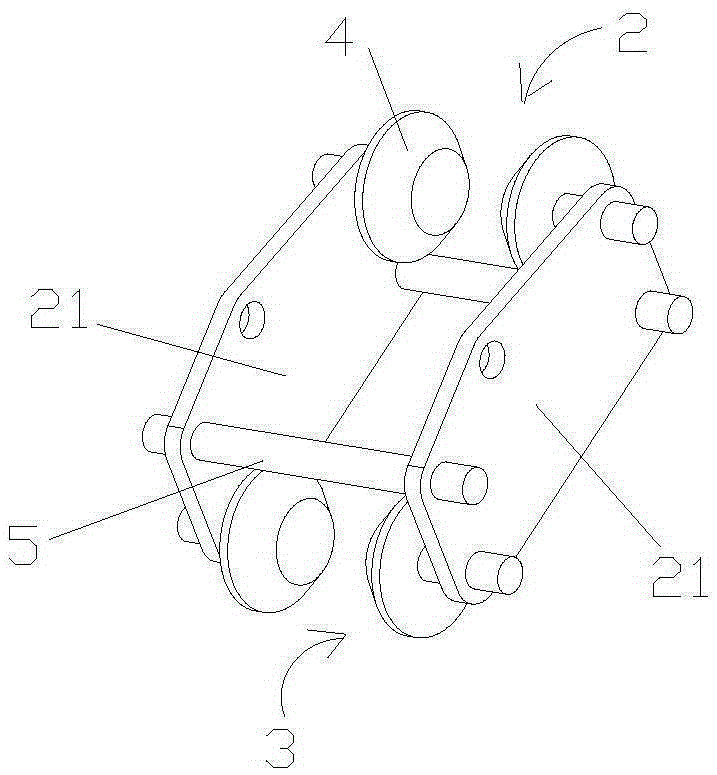

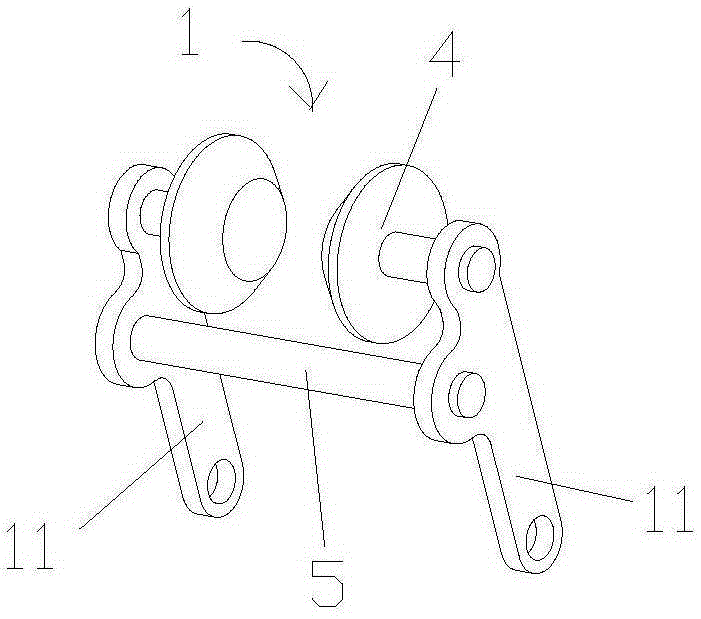

Rotation-controlled high altitude cable robot climbing mechanism

A robot and cable technology, applied in the field of cable-stayed bridge cable detection robots, can solve the problems of surface protection layer damage, wire breakage and lifting, troublesome adjustment, etc., achieving strong pipe diameter adaptability, complete and comprehensive detection, and control. Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: Each probe includes a section of arc probe and a needle valve.

Embodiment 2

[0075] Embodiment 2: Each probe includes a section of arc-shaped probe and two needle valves arranged parallel to each other.

[0076] As an alternative, the number of needle valves may also be 3 or more, all of which are within the protection scope of the present application.

[0077] One end of each needle valve is fixedly connected to the arc probe, preferably the top of the needle valve is fixedly connected to the middle of the arc probe.

[0078] The other end of the needle valve is floatingly connected with the switch body, and the needle valve can trigger the conduction and disconnection of the switching signal in the switch body.

[0079] The above-mentioned arc probes are arranged coaxially and can be enclosed to form a ring structure. Preferably, the ends of the arc-shaped probes are spliced together to form a ring. As an alternative, the head and tail of the arc probe can only be close to each other without splicing relationship, or the arc probe is not concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com