Flow guide plate capable of reducing airflow resistance

A technology of airflow resistance and deflector, used in engine components, machines/engines, mechanical equipment, etc., can solve the problems of increased exhaust pressure of low-pressure cylinders, inability to reduce exhaust pressure, large flow resistance, etc. Steam pressure, simple structure, the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

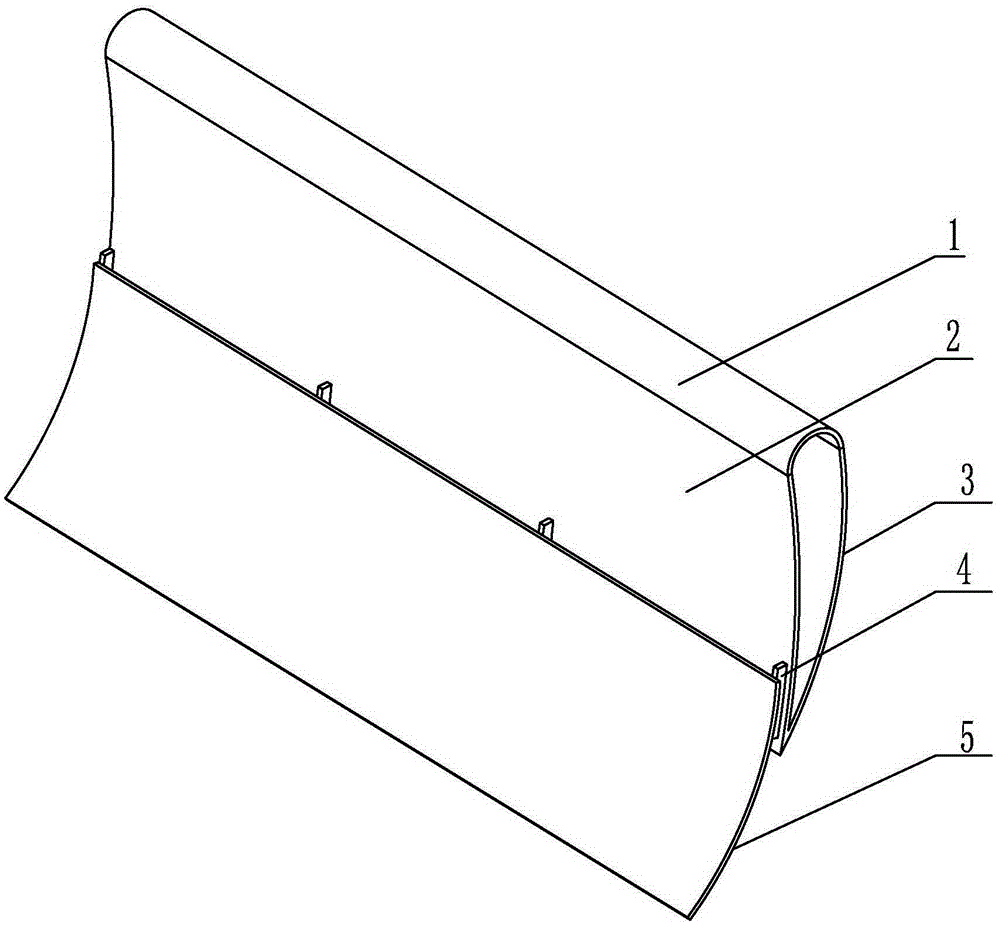

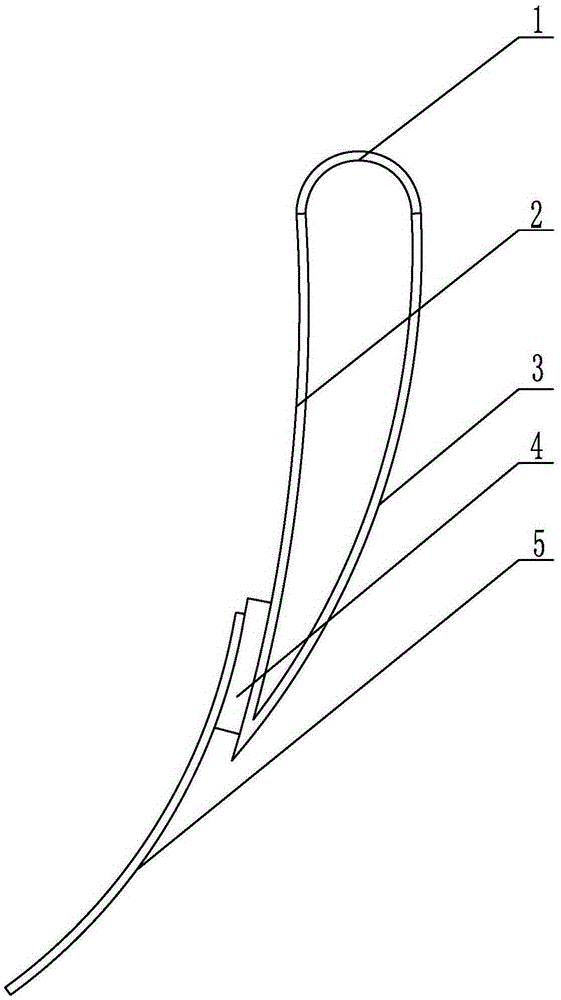

[0014] exist figure 1 , 2 Among them, the deflector for reducing airflow resistance in this embodiment is composed of a blunt head 1 , a pressure side arc plate 2 , a suction side arc plate 3 , a rib plate 4 , and an arc plate 5 .

[0015] In this embodiment, the front end of the blunt head 1 is in contact with the upper end of the pressure side arc plate 2, the blunt head 1 is tangent to the outer contour of the pressure side arc plate 2, and the rear end of the blunt head 1 is in contact with the suction side. The upper end of the arc plate 3 is kissed, the blunt head 1 is tangent to the outer contour of the suction side arc plate 3, the lower end of the pressure side arc plate 2 is kissed with the lower end of the suction side arc plate 3, the geometry of the blunt head 1 The shape is semicircular with a radius of 54mm; the geometric shape of the pressure side arc plate 2 is circular arc with a radius of 1348mm and a central angle of 20°; the geometric shape of the suction...

Embodiment 2

[0017] In this embodiment, the geometric shape of the blunt head 1 is a semicircle with a radius of 38 mm; the geometric shape of the pressure side arc plate 2 is circular arc with a radius of 1250 mm and a central angle of 14°; The geometric shape is arc-shaped, the radius is 600mm, and the central angle is 39°. The geometric shape of the arc plate 5 is arc-shaped, the radius is 490mm, and the central angle is 40°. The pressure side arc plate 2 and the suction side arc plate 3 The center of circle of is positioned at the same side; All the other parts and the connection relation of parts are identical with embodiment 1.

Embodiment 3

[0019] In this embodiment, the geometric shape of the blunt head 1 is a semicircle with a radius of 66.5 mm; the geometric shape of the pressure side arc plate 2 is circular arc with a radius of 1450 mm and a central angle of 22°; the suction side arc plate 3 The geometric shape of the arc plate is arc-shaped with a radius of 750mm and a central angle of 47°. The geometric shape of the arc plate 5 is arc-shaped with a radius of 530mm and a central angle of 50°. The pressure side arc plate 2 and the suction side arc plate The center of circle of 3 is positioned at the same side; All the other parts and the connection relation of parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com