Air-fuel ratio control system and control method for biogas internal combustion generator set

A technology of internal combustion generators and generator sets, applied in engine control, internal combustion piston engines, electrical control, etc., can solve the problems of control lag, failure to consider the influence of cylinder temperature and combustion state, and unstable speed, etc., to achieve accurate air control Fuel ratio, favorable gas mixing, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

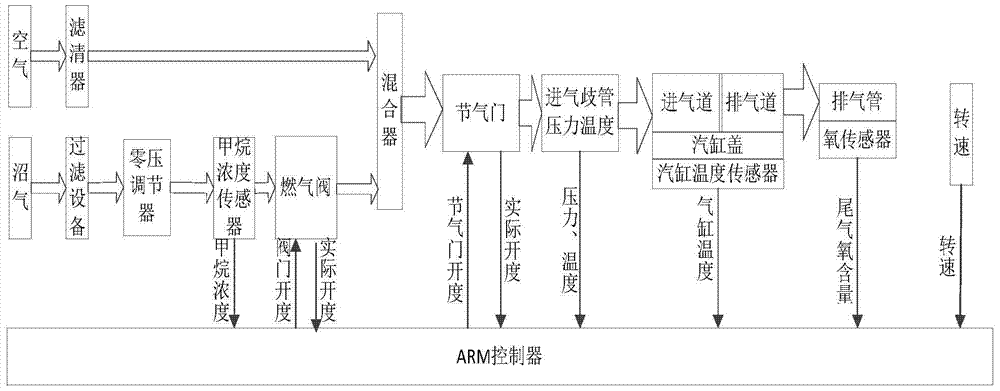

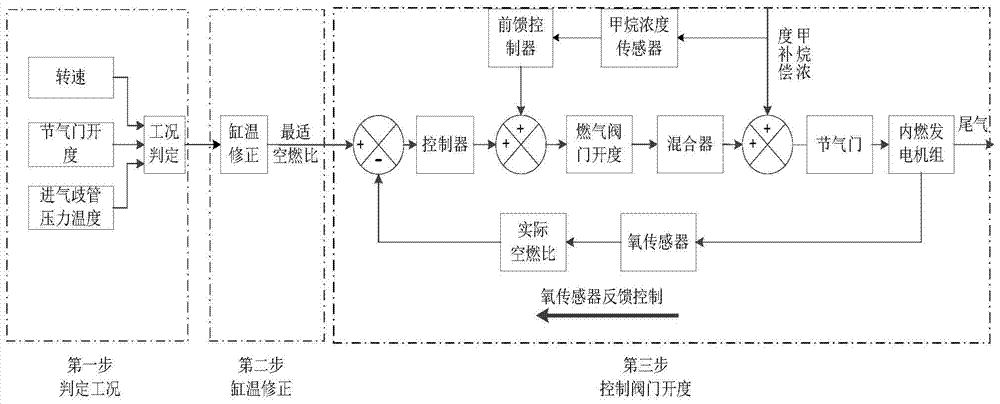

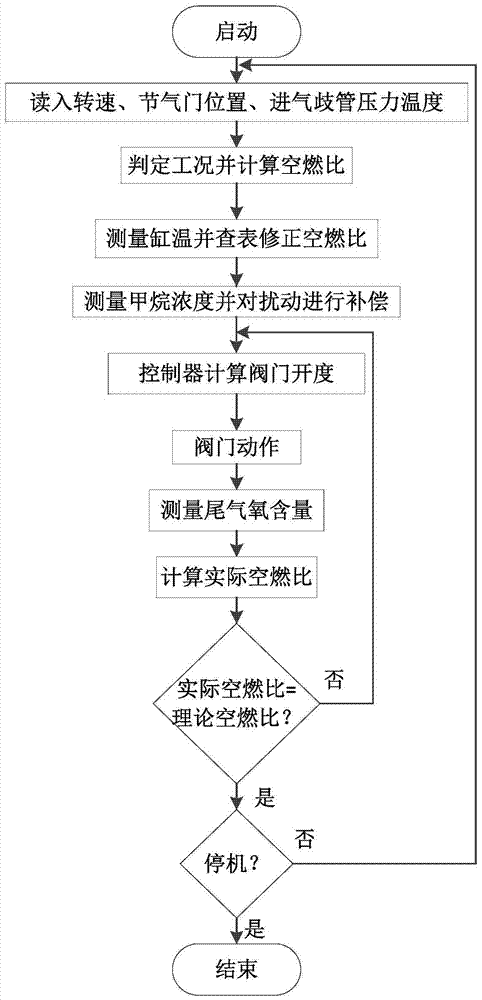

[0032] figure 1 It is a schematic structural diagram of the air-fuel ratio control system of the biogas internal combustion generator set of the present invention, combined with figure 1 This control system of the present invention is described as follows:

[0033] The invention controls the air-fuel ratio through the feedback of the oxygen sensor, introduces the methane concentration feed-forward control, and comprehensively considers the working conditions of the internal combustion engine to precisely control the air-fuel ratio. The air-fuel ratio control system of biogas internal combustion generator set of the present invention comprises:

[0034] An air intake pipe and a biogas intake pipe, both of which are connected to the inlet of the mixer, and a gas valve is also arranged at the connection between the biogas intake pipe and the mixer, and the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com