A small-flow miniature solenoid valve and its assembly and adjustment method

A solenoid valve, small flow technology, applied in the direction of valve device, valve details, valve operation/release device, etc., can solve the problems of low control precision and inconvenient adjustment method, achieve high measurement accuracy and avoid rubber modification problems , to avoid the effect of spool wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

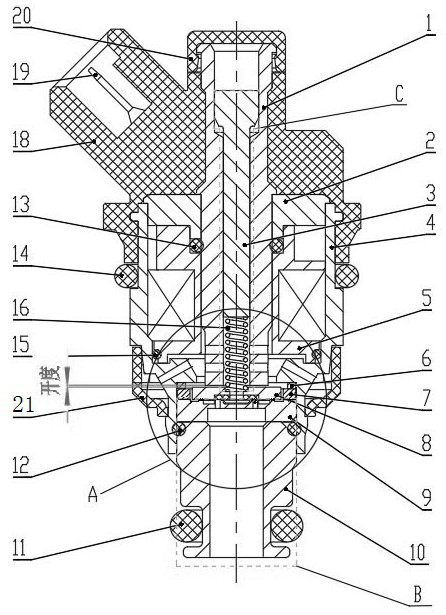

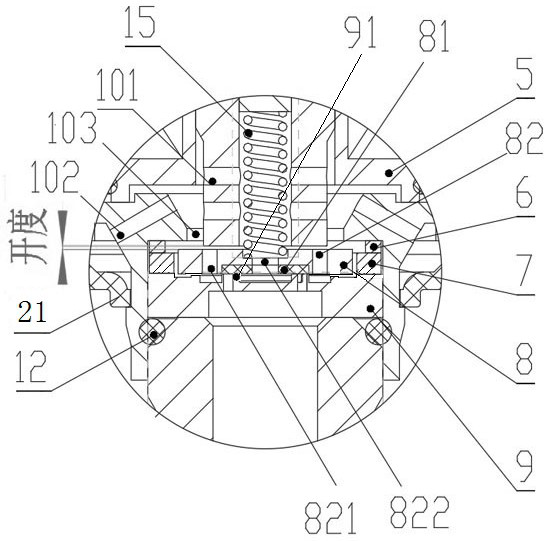

[0041] Embodiment 1, a kind of small flow miniature solenoid valve, such as figure 1 As shown, it includes a split valve body, and the valve body includes a split end housing 18, an intermediate housing 4, and an air outlet joint 10, and the end housing 18, the intermediate housing 4, and the air outlet joint 10 are detachably connected. .

[0042] A magnetizable sleeve 1 is arranged in the valve body, and a coil assembly 5 is arranged between the sleeve 1 and the valve body. The step platform 19 is axially fixed. The outer periphery of the armature 8 is provided with a magnetic isolation ring 7 , and the armature 8 can move axially under the magnetization of the coil assembly 5 . The lower end of the armature 8 is provided with a valve seat 9, and the top of the armature 8 is provided with a spring 16 that presses the armature 8 on the valve seat 9. When the coil assembly is not energized, under the elastic force of the spring 16, the armature 8 and the valve seat 9 Crimp ...

Embodiment 2

[0056] Embodiment 2, an assembly and adjustment method of a small-flow miniature solenoid valve, the end casing 18 is injected outside the sleeve 1, and the stopper 2 is installed outside the sleeve 1 before or after the injection molding of the end casing 18, and then The coil assembly 5 and the intermediate housing 4 are installed on the sleeve 1 and are clamped and fixed with the end housing 18. The second end of the intermediate housing 4 is installed with an adjusting pad 6, a magnetic isolation ring 7, an armature 8, and a valve seat 9. The intermediate housing 4 outside the seat 9 is connected with an air outlet joint 10 .

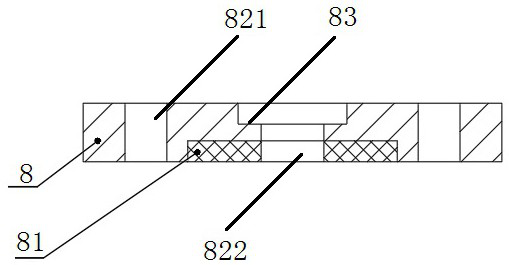

[0057] Further, the adjustment pin 3 and the spring 16 are inserted from the adjustment end or the other end of the sleeve 1, and the spring 16 is separately installed between the armature 8 and the adjustment pin 3 or is assembled with the installation groove 83 of the armature 8 and synchronized with the armature 8 Install.

[0058] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com