Commercial charcoal kitchen range with waste heat utilization function

A commercial, charcoal stove technology, applied in household stoves/stoves, stoves/stoves with hot water devices, applications, etc., can solve the problems of energy waste of ordinary stoves, achieve low manufacturing cost, high reliability, and easy replacement The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

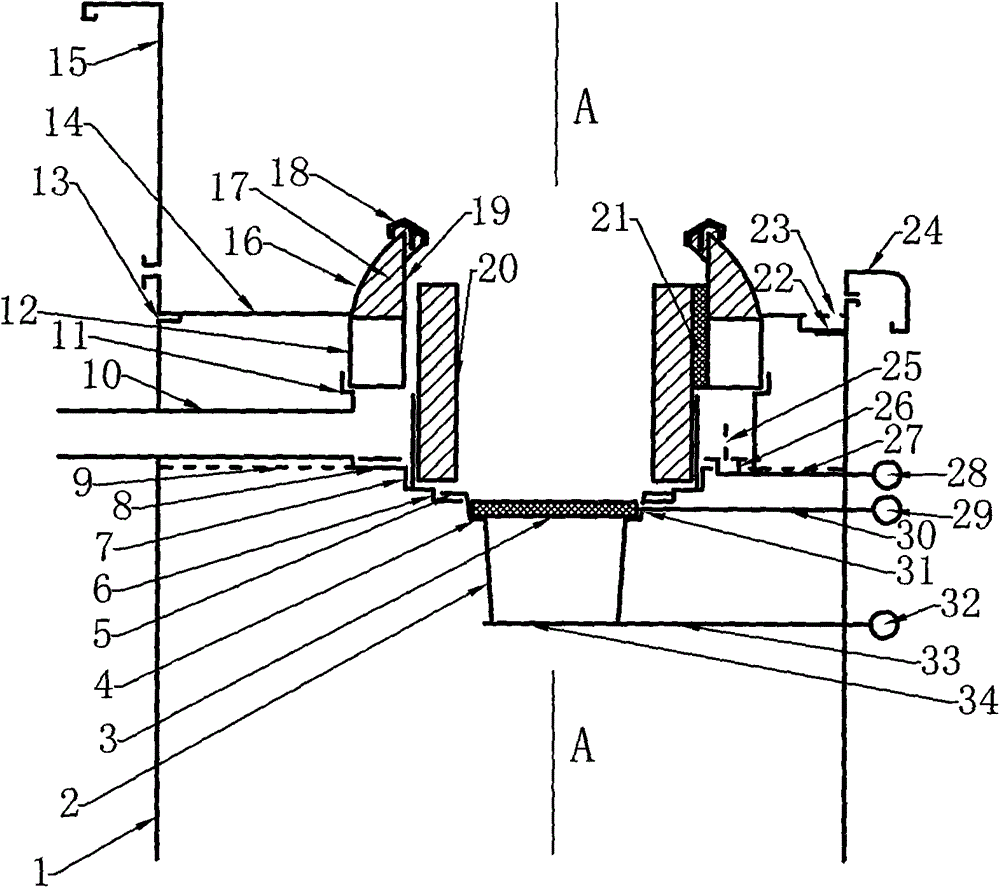

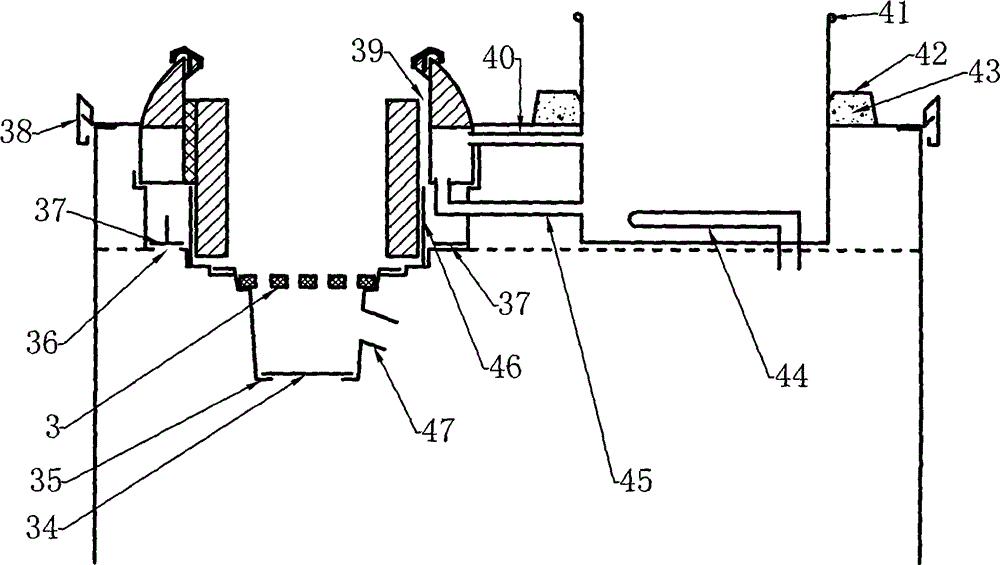

[0023] The accompanying drawings describe a structural form of a commercial charcoal stove utilizing waste heat. A commercial charcoal stove utilizing waste heat mainly consists of a bracket, a waste heat recovery device, a base, a refractory furnace core, an ash hopper, and a bucket. The legs 1, the lower frame 9, and the upper frame 13 together form a bracket; the waste heat recovery device 12 is a hollow metal body with a cylindrical shape, or a truncated cone shape, or a prism shape, or a truncated prism shape; the waste heat recovery device has a ring-shaped wing plate upward 19. The ring-shaped wing plate is a cylindrical, or truncated, or prism-shaped, or prism-shaped cylindrical metal body; the fixed step 11 of the waste heat recovery device, the fixed step 8 of the ash discharge plate, and the fixed step 7 of the refractory furnace core 1. The fixed steps 6 of the ash hopper are connected with each other to form a base; the shape of the upper end of the base is adapte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com