Ultrasonic transducer installation structure and ultrasonic flowmeter

A technology for installing structures and transducers, which is used in the measurement of flow/mass flow, liquid/fluid solid measurement, instruments, etc. It can solve the problem of inability to measure fluid flow in small diameter pipelines, and avoid energy decomposition and refraction loss. , the effect of improving the transmission intensity and prolonging the transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

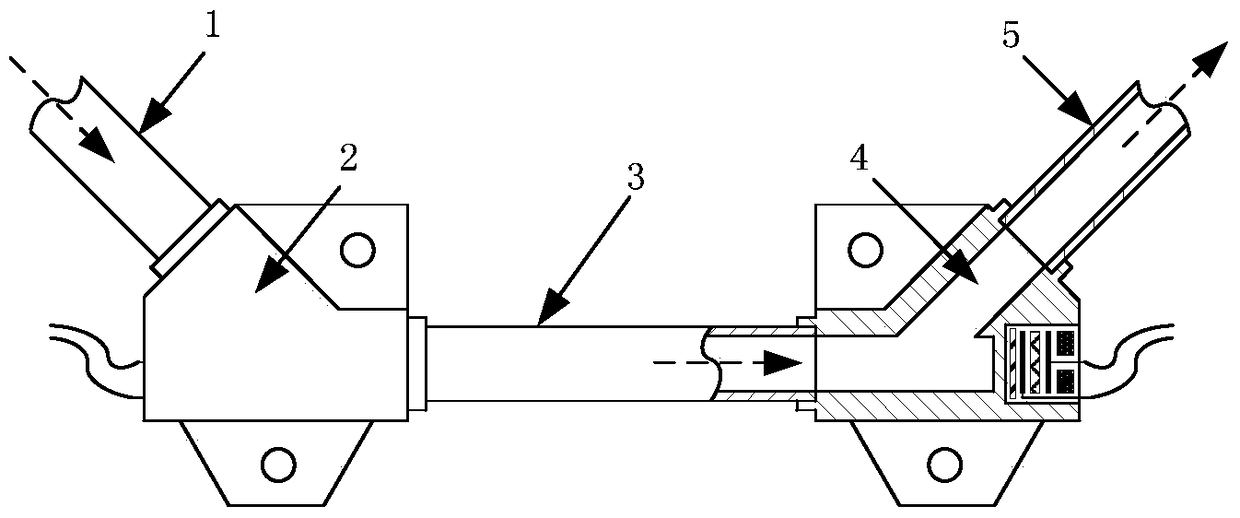

[0040] see figure 1 , 2 , an ultrasonic flowmeter, comprising an upstream pipeline 1, an upstream transducer mounting structure 2, a measuring pipeline 3, a downstream transducer mounting structure 4 and a downstream pipeline 5, the structural body material is titanium alloy, and the measuring pipeline The inner diameter is 10mm, these 5 parts are connected by plug welding, and the length of the measuring pipeline is 150mm.

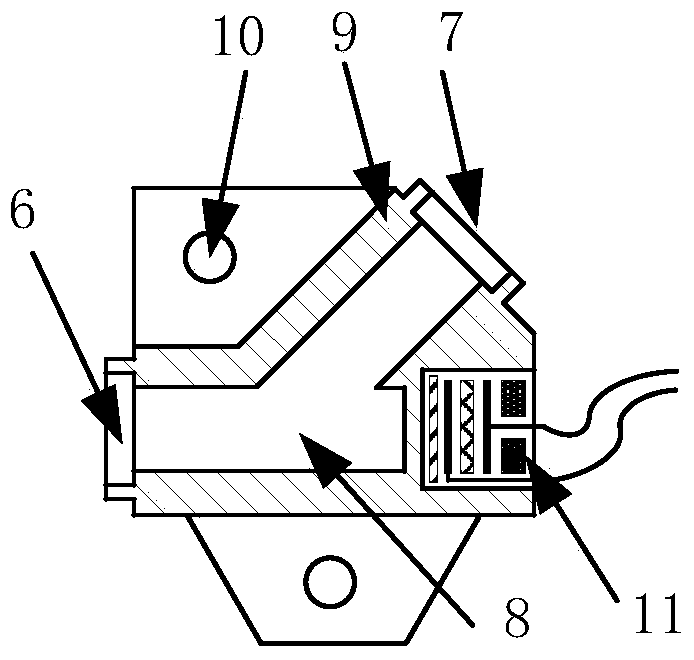

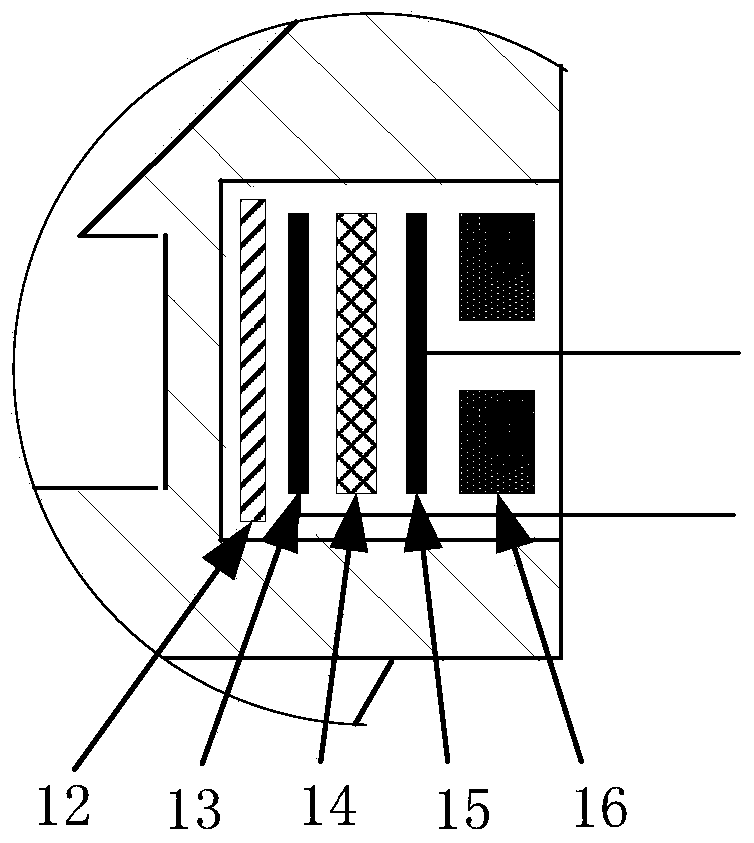

[0041] Both the upstream transducer mounting structure 2 and the downstream transducer mounting structure 4 include a structural body and an ultrasonic transducer, wherein the structural body includes a first mounting interface, a second mounting interface and a fluid channel, and the first mounting interface It is used to connect the measuring pipeline 3, the second fitting is used to connect the upstream pipeline 1 or the downstream pipeline 5, and the fluid passage is formed inside the structural body and arranged between the first fitting and the Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com