Surface phasmon coaxial optical waveguide structure

A surface plasmon and waveguide structure technology, applied in the field of optical waveguides, to reduce noise optical signals, increase propagation distance, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

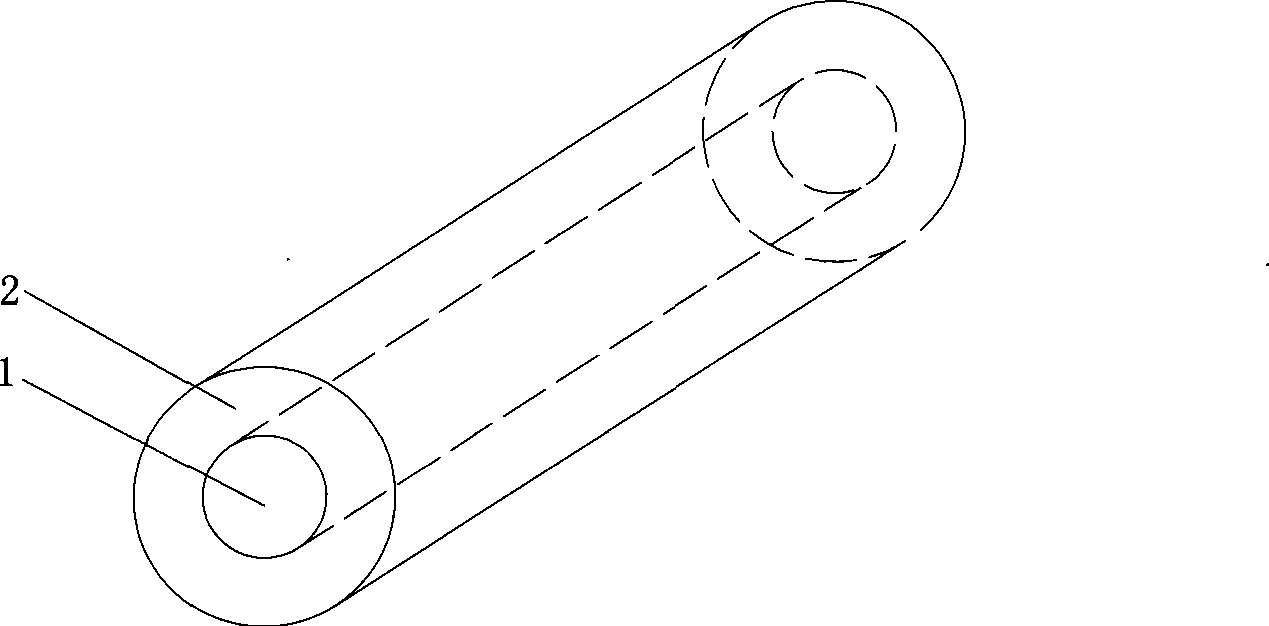

[0019] Surface plasmon coaxial waveguide structure such as figure 1 shown. The structure consists of a cylindrical metal core 1 and a tubular wide bandgap dielectric shell 2 . Wherein the core layer 1 adopts metal zinc, and the dielectric shell layer 2 adopts wide band gap zinc silicate. The diameter of the cylindrical metal core layer is 50nm, and the thickness of the tubular wide-bandgap dielectric shell layer is 25nm, which is less than the half-wavelength of the light wave with a propagation wavelength of 300nm. The structure can be prepared by using a quartz tube as a reaction chamber, using flowing nitrogen as a protective gas, and metal zinc powder as a raw material, and reacting and forming on a single crystal silicon substrate. Experimental measurement results show that the resonant cavity provided by surface plasmons in this embodiment has a small mode volume, and its fineness is 10 times and 33 times higher than that of the whispering gallery mode and waveguide mo...

Embodiment 2

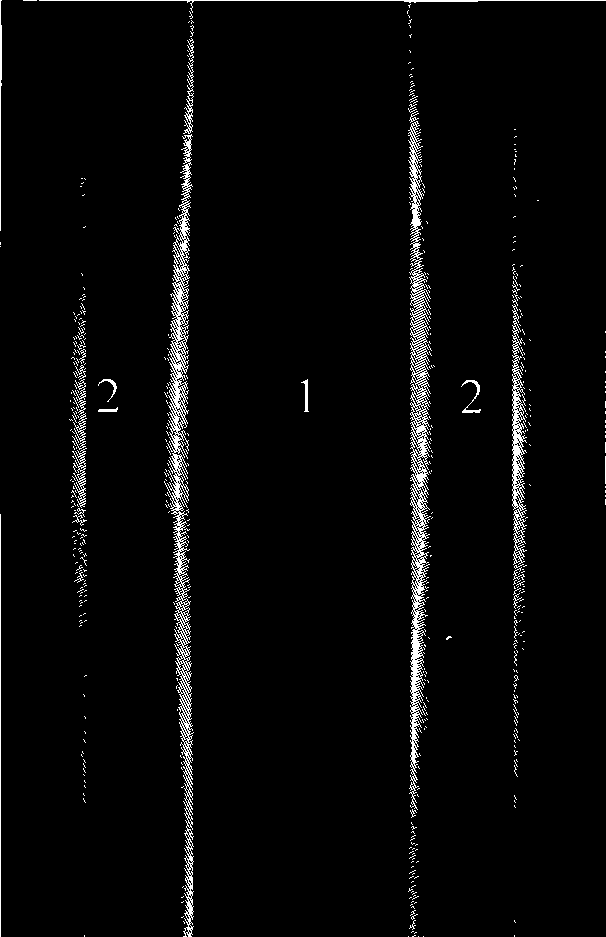

[0021] Similar to Example 1, the difference is that silicon dioxide is used as the shell dielectric material to obtain different target wavelengths. The target wavelength corresponding to this structure is 348nm. For the simulated electromagnetic field distribution, see image 3 , the light energy gain is more than 5 times. It can be seen that by changing the types of core metal material and shell wide bandgap dielectric material, surface plasmon coaxial optical waveguide structures with different target wavelengths can be designed.

Embodiment 3

[0023] Similar to Embodiment 1, the difference is that a gold core layer is used, the diameter of the gold core layer is 10 nm, and the dielectric material of the shell layer is a zinc oxide shell layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com