Ultrasonic method for flow measurement and device thereof

A flow measuring device and ultrasonic technology, applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc. The effect of improving measurement accuracy and reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

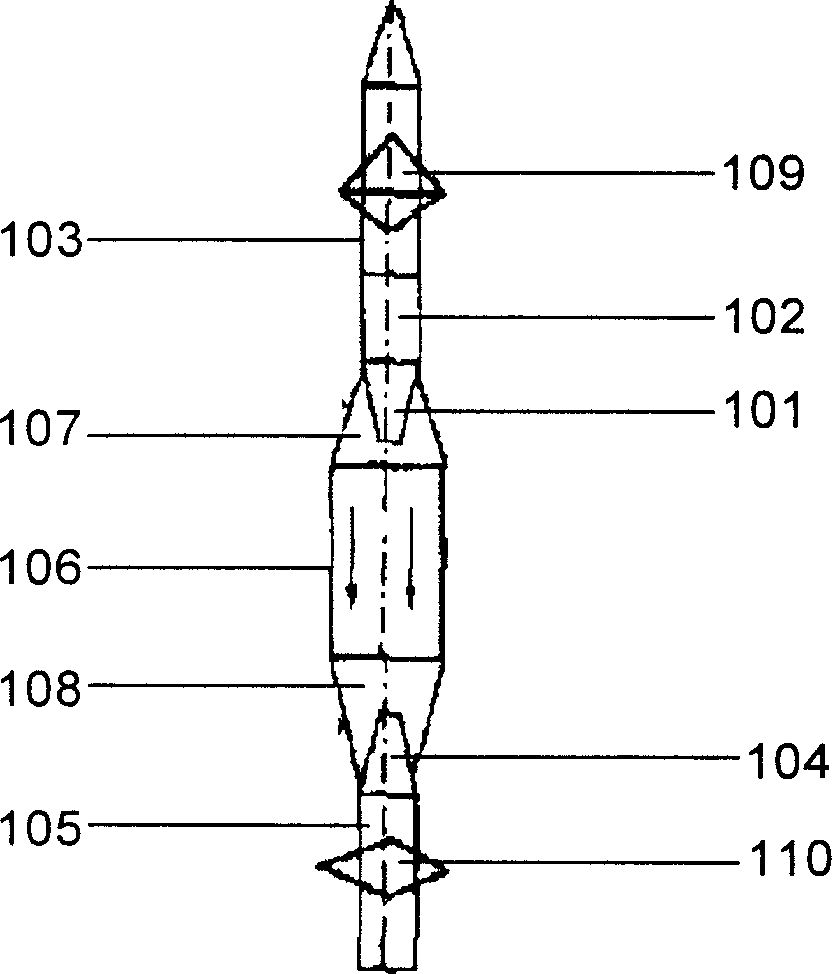

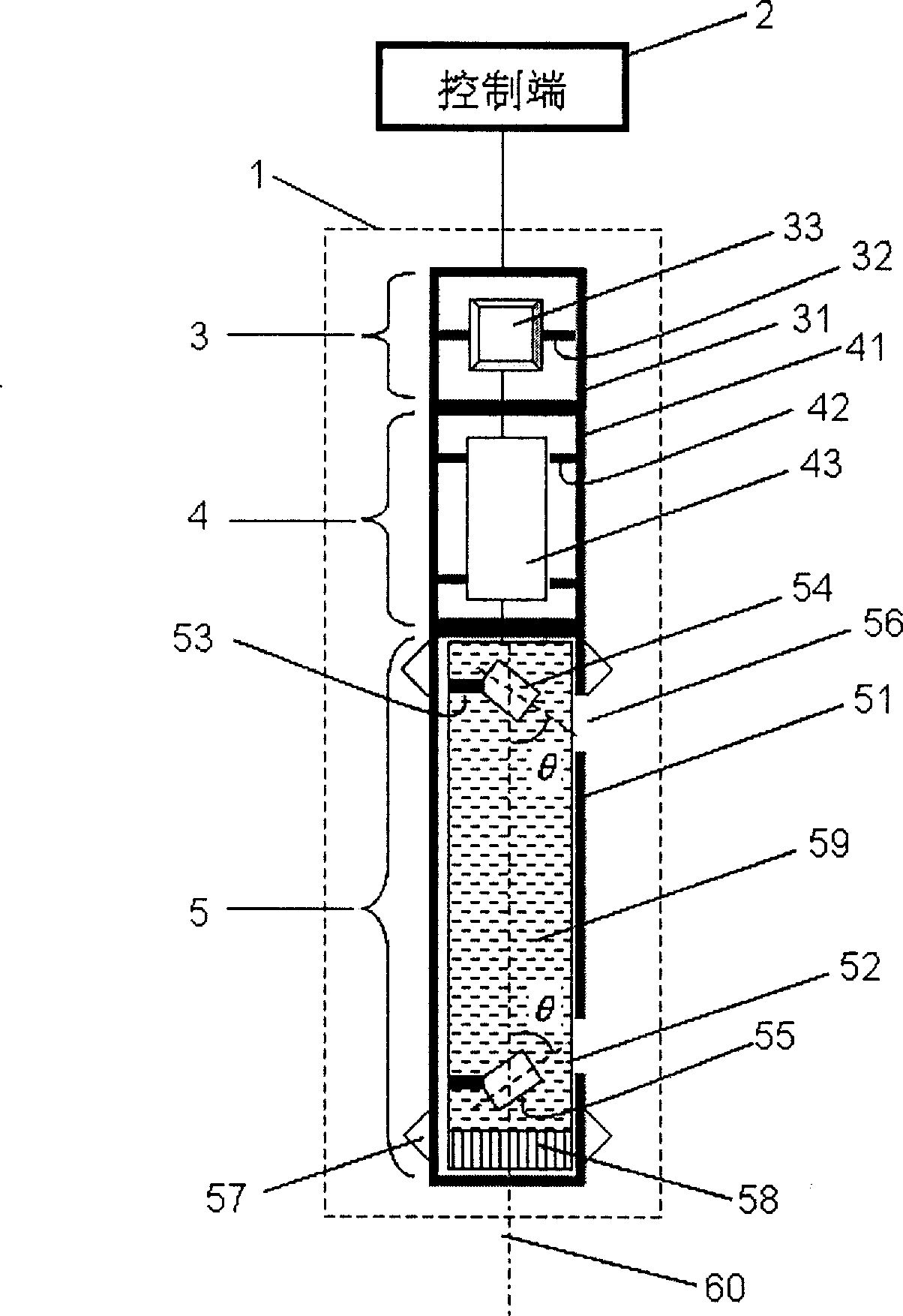

[0041] refer to figure 2 An ultrasonic flow measuring device is manufactured, wherein the measuring end 1 will be used in an underground well, the control end 2 is above the ground, and the measuring end 1 and the control end 2 are connected by cables.

[0042] In order to allow the device to withstand enormous pressure when working in deep wells, the first protection tube 31, the second protection tube 41 and the mechanical frame 51 are all made of stainless steel plate material with a thickness of 5mm, and are sequentially connected together by threads; The first protective tube 31 has a length of 500 mm and a diameter of 45 mm; the second protective tube 41 has a length of 800 mm and a diameter of 45 mm; the mechanical skeleton 51 has a length of 900 mm and a diameter of 45 mm.

[0043] The transmission module 33 of the transmission sub-section 3 adopts the 8248E special transmission module of Western Atlas Company, which is responsible for loading the encoded signal compl...

Embodiment 2

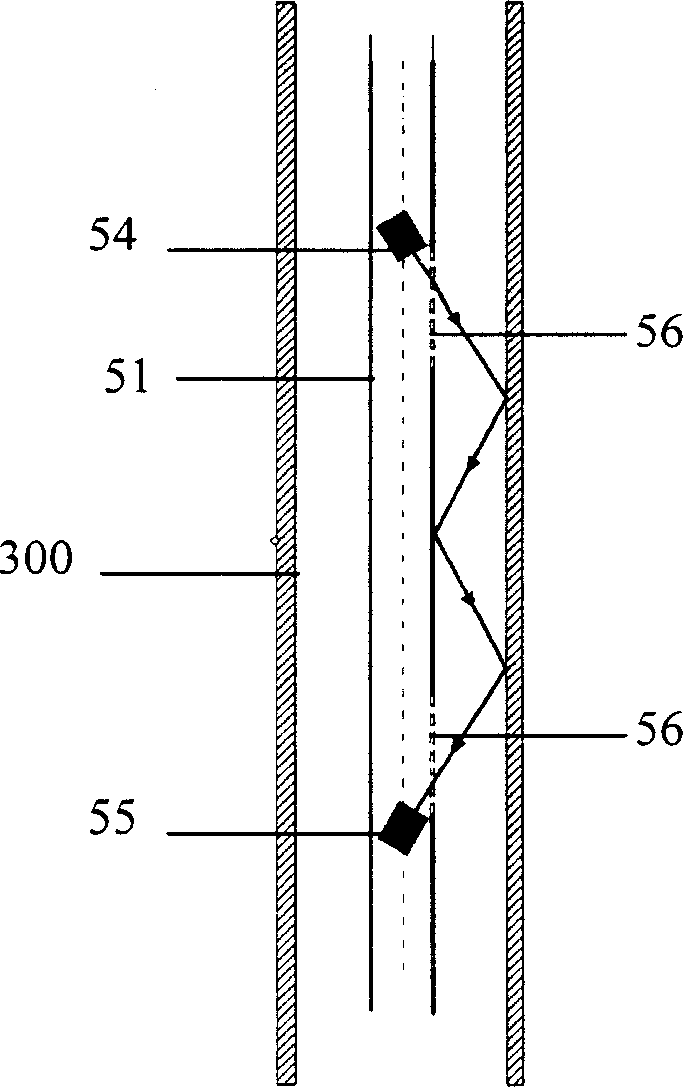

[0061] refer to figure 2 Make an ultrasonic flow measurement device. Wherein, the included angle between the emission directions of the first transducer 54 and the second transducer 55 and the acoustic system axis 60 is θ=50°; Two sets of compressible lantern-like support structures at the end.

[0062] Others are the same as in Example 1.

Embodiment 3

[0064] refer to figure 2 Make an ultrasonic flow measurement device. Wherein, the included angle between the emission directions of the first transducer 54 and the second transducer 55 and the acoustic system axis 60 is θ=55°.

[0065] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com