Low-temperature mechanical test method with automatic sample exchange

A technology of mechanical test and low temperature test, applied in scientific instruments, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve problems such as loss of cold air in the low temperature test box, waste of resources such as manpower, and long test preparation time. , to save test time and cost, increase personal safety, and reduce human operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

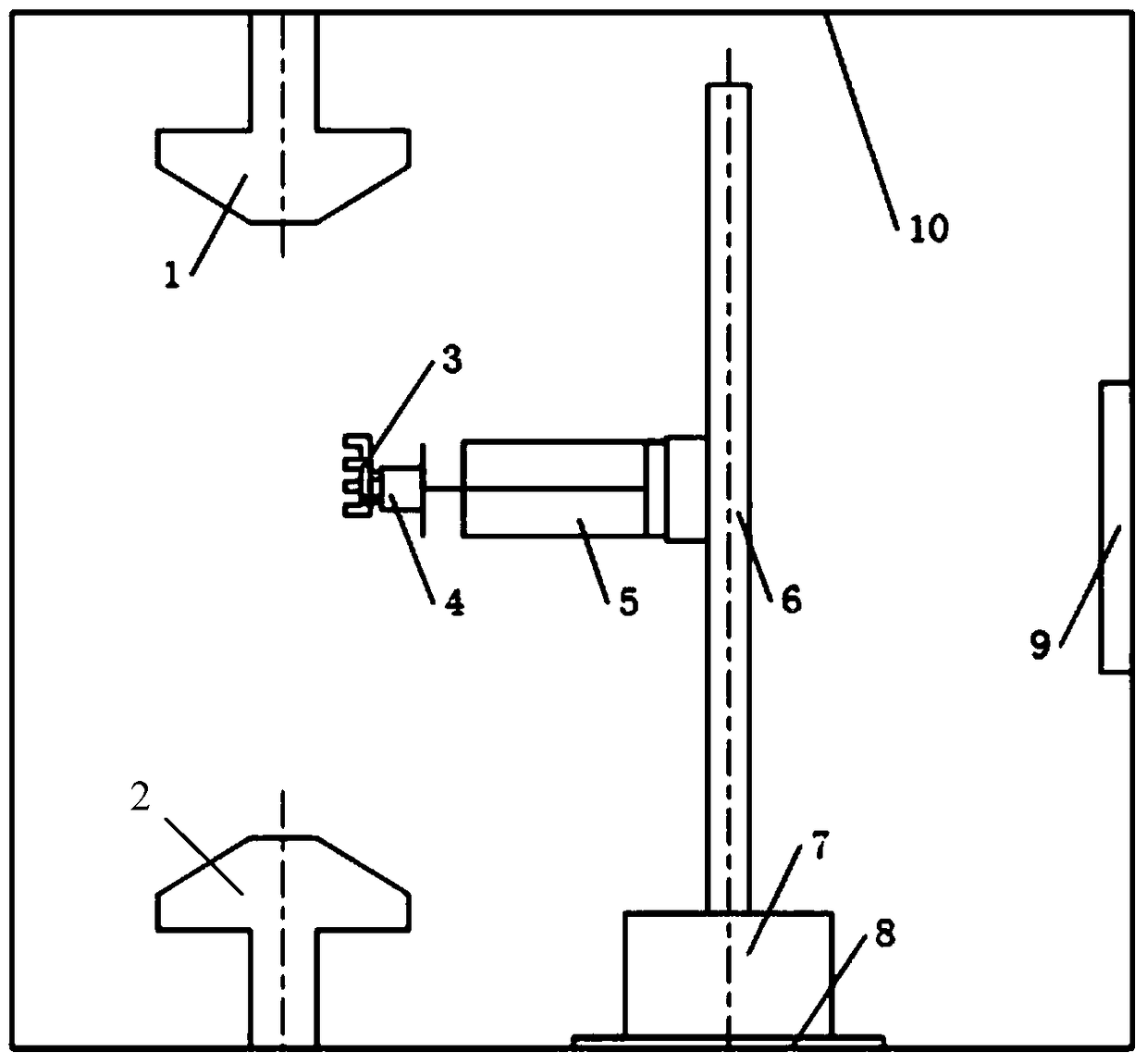

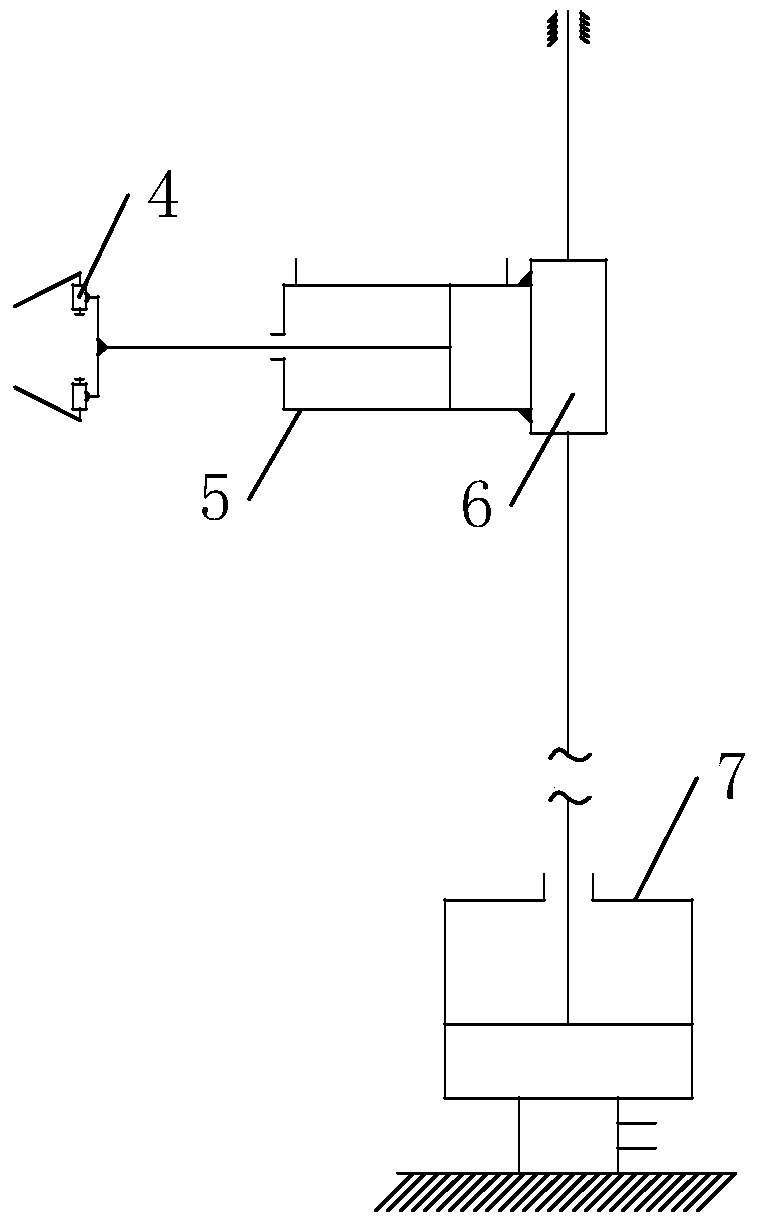

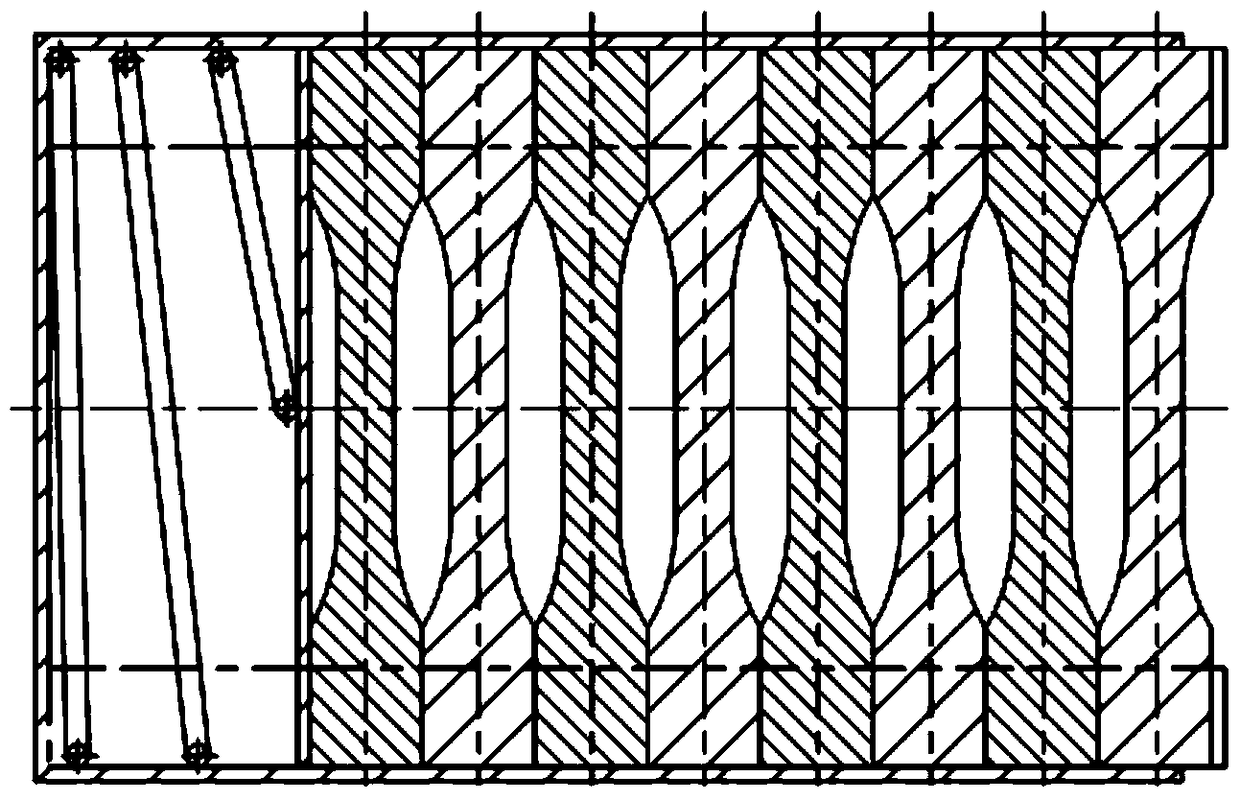

[0030] like figure 1 and 2 As shown, the low-temperature mechanical test device for automatically changing samples includes tooling fixture 3, parallel gripper 4, translation cylinder 5, linear drive 6, rotating cylinder 7, sample pre-cooling frame 9, control system and low-temperature test chamber 10. The rotary cylinder 7 is fixed on the bottom of the low temperature test chamber 10 through the bottom plate 8; the linear drive 6 is fixed to the piston rod of the rotary cylinder, and the upper and lower positions of the translation cylinder 5, the parallel gripper 4 and the fixture 3 are realized for different sample lengths. down movement function, and transmit its own displacement parameters to the control system at the same time; the translation cylinder 5 is fixed on the linear driver to realize the left and right movement functions of the parallel gripper and the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com