LCD bare chip detection unit framework and detection method

A detection unit and detection method technology, which is applied in the direction of optical testing defects/defects, can solve the problems of increased test time and unstable camera pictures, and achieve the effects of stabilizing the test environment, reducing color and light interference, and improving test accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

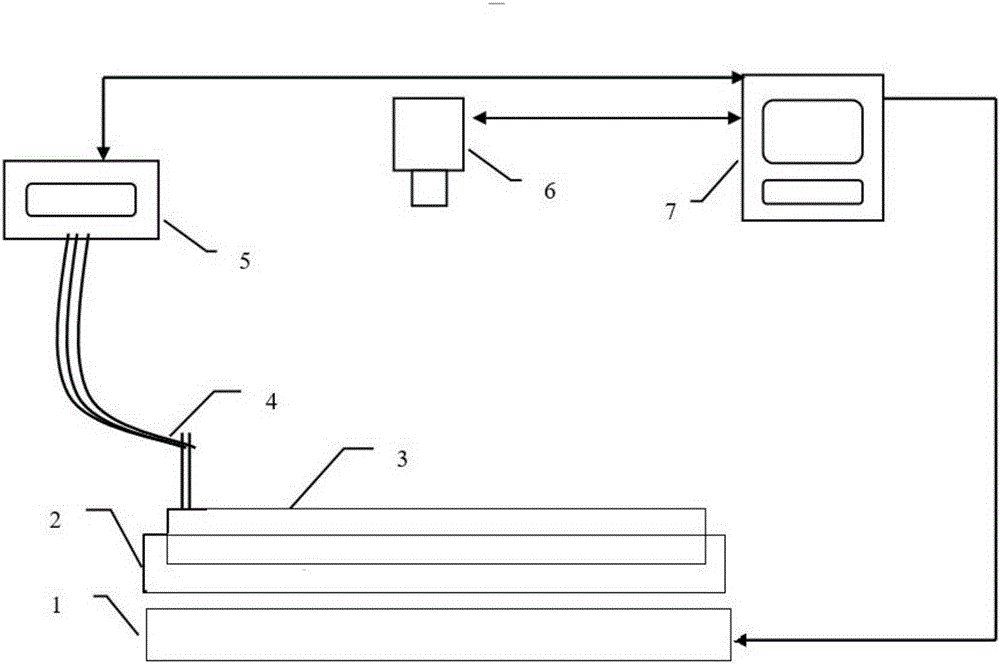

[0028] A kind of LCD bare chip detection unit framework, comprises the following device composition: a bare chip stage 2, is used to place the bare chip 3 for testing; A light source 1, is arranged under described bare chip stage, is used for illuminating described bare a chip; a camera 6, used to acquire the image of the die, and send the image to the control unit; a signal unit 5, connected to the die carrier through the connection line 4, and controlled by the control unit; a control unit 7, generally a computer , connected to the light source, camera, and signal unit, capable of controlling the light source to emit corresponding lighting, controlling the operation of the camera and receiving the image sent by it, and controlling the signal unit and receiving the response signal sent by it. The light source 1 is a backlight light source with RGB three colors that can be controlled separately.

[0029] Detection method of the present invention is as follows:

[0030] S1: Th...

Embodiment 2

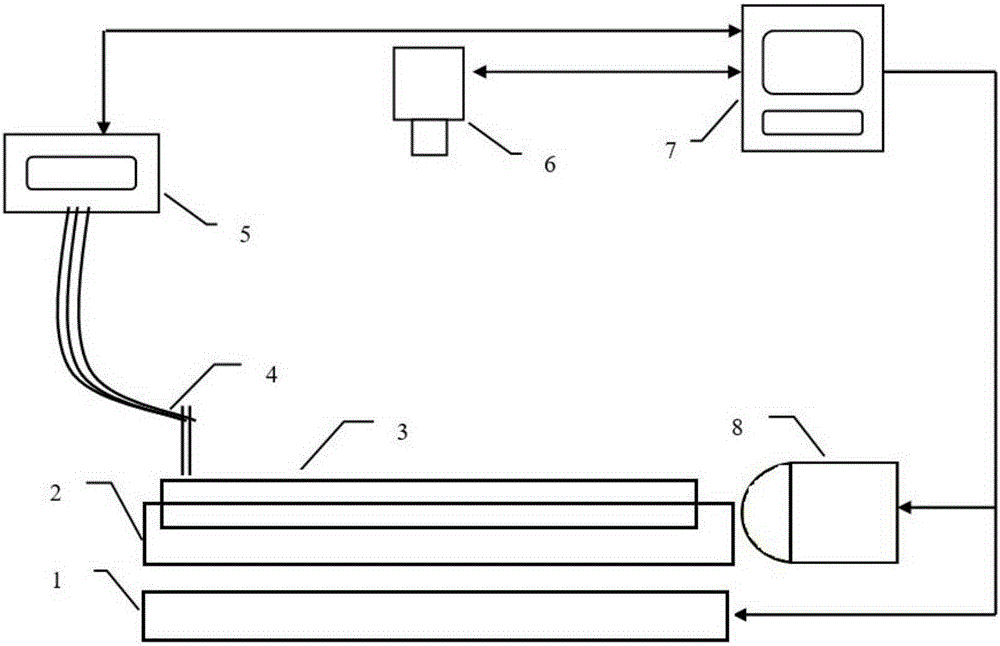

[0049] The difference from Embodiment 1 is that a side light source 8 is placed on one side of the die carrier 2 , and the side light source 8 is connected to and controlled by the control unit 7 .

[0050] The detection method is different in that after step S4, the light source is switched to the side light source, the camera captures the corresponding image, the calculation control unit analyzes the surface foreign matter information of the die, and the calculation control unit calculates the surface foreign matter in the corresponding position. defects are eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com