Simulation based high-altitude calibration method for high-pressure common rail diesel engine

A high-voltage common rail and calibration method technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of shortening the development cycle development cost, long test cycle, high test cost, etc., to achieve calibration workload and development Effects of cost reduction, shortened development cycle, and reduced development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

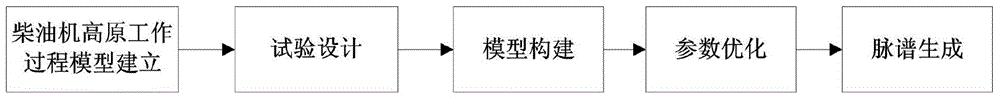

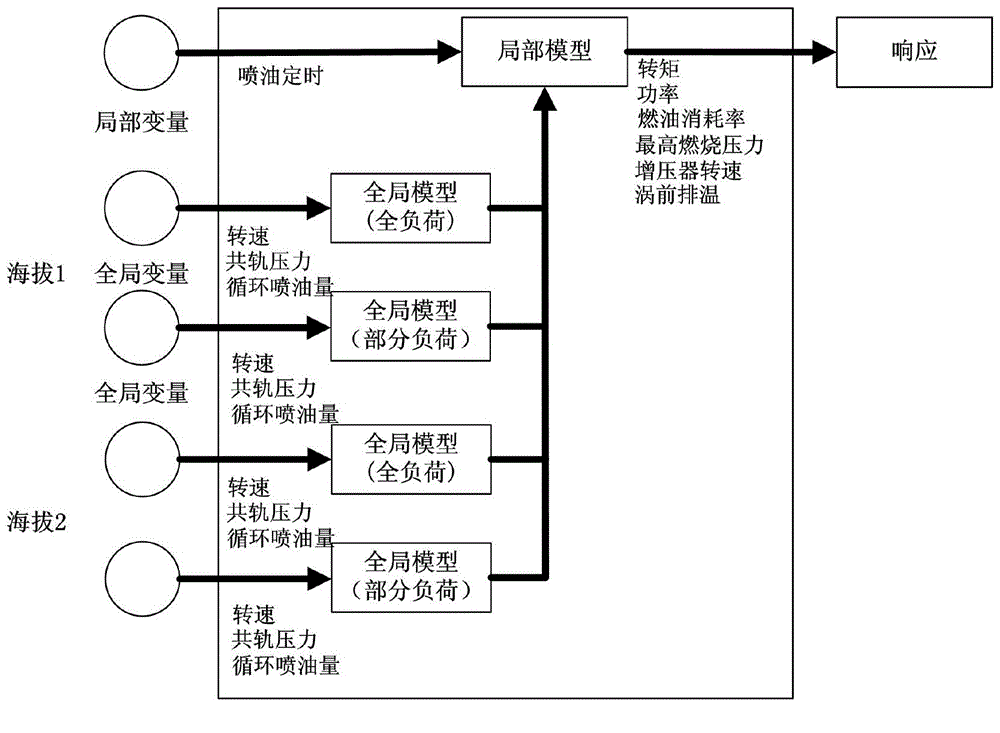

[0018] As shown in the figure: a simulation-based high-altitude calibration method for high-pressure common rail diesel engines, including five steps of engine plateau working process model establishment, test design, model construction, parameter optimization, and map generation. Specific steps are as follows:

[0019] (1) The engine plateau working process model is established. The engine performance simulation software is used to simulate the engine plateau working process model. This model serves as the basis of simulation-based calibration and acts as a "virtual engine".

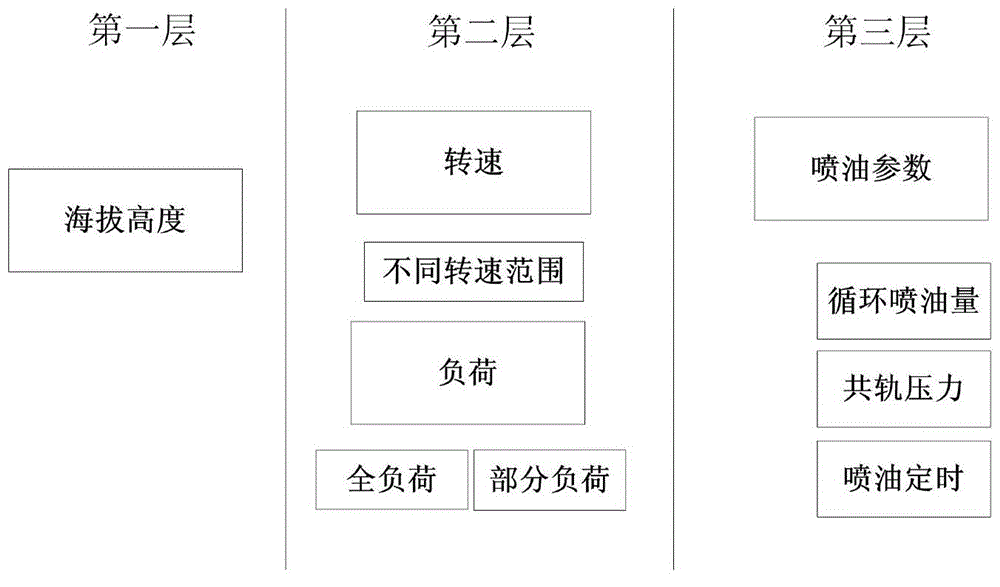

[0020] (2) Experimental design

[0021] Experimental design technology is one of the effective technologies to reduce the workload of electronically controlled engine calibration, and can obtain more experimental information with fewer experimental points. Classical design method, space-filling design method, optimal design method, etc. are commonly used methods in experimental design. The above three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com