Method and device for determining the clearance amount of the die surface

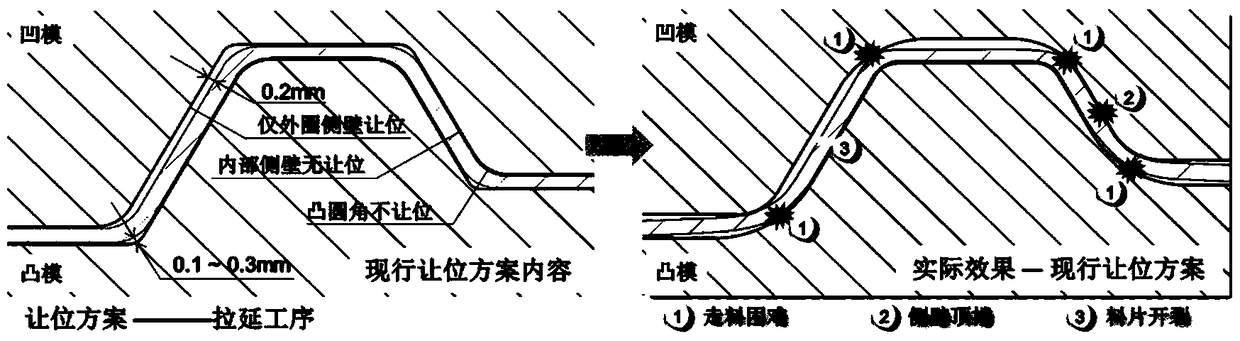

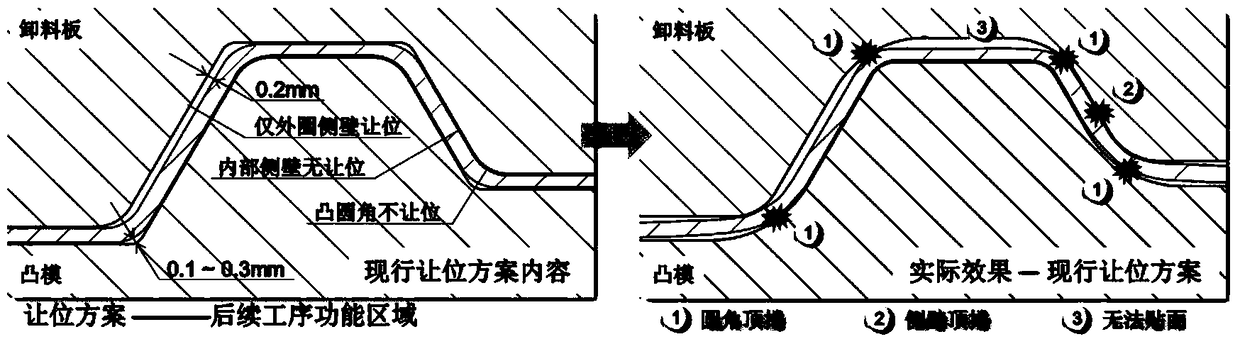

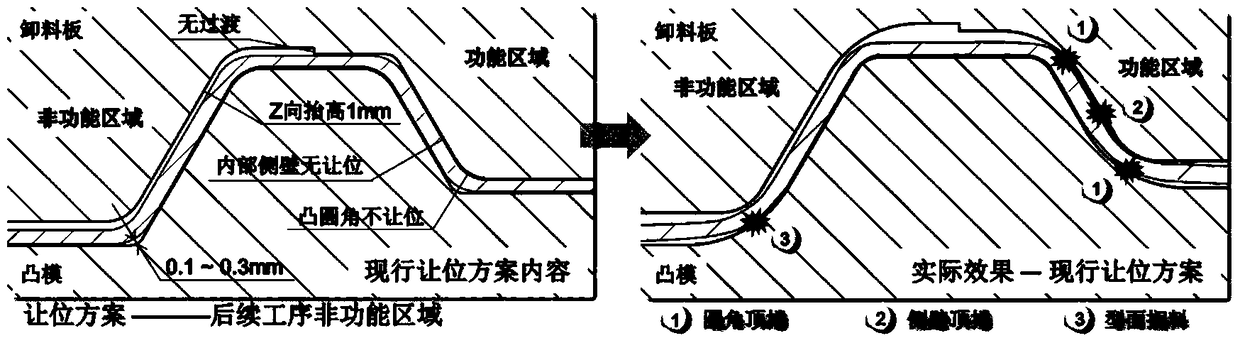

A determination method and technology for determining devices, which are applied in special data processing applications, instruments, electrical and digital data processing, etc., and can solve problems such as inability to veneer, material rupture, and difficulty in feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

[0042] The method for determining the clearance amount of the mold surface of the present invention can be used in the field of automobile outer cover molds, and can also be used in other related fields, such as the field of sheet metal stamping dies, the field of mechanical processing, and the like. Embodiments of the present invention are described by taking a mold for an automobile outer cover as an example.

[0043] figure 2 A schematic diagram showing a preferred embodiment of the method for determining the amount of clearance of the mold surface of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com