A method and device for early warning of abnormal operation of substation equipment

A technology of equipment abnormality and early warning device, which is applied to circuit devices, transformer/inductor cooling, electrical components, etc. Large quantity, easy operation, and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

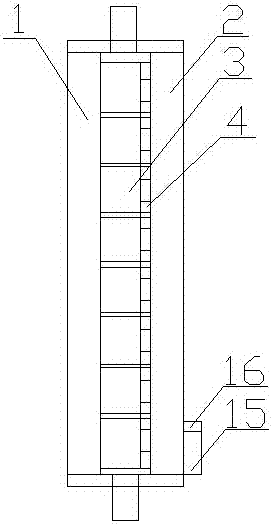

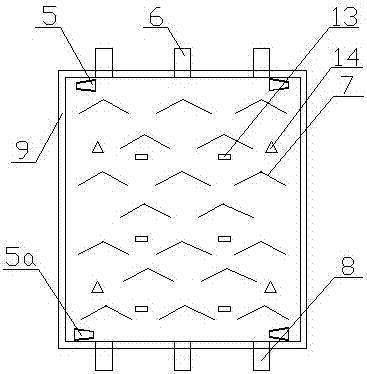

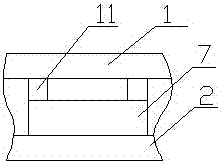

[0049] Embodiment 1: A pre-warning device for abnormal operation of substation equipment, including a transformer wall 1 whose back is connected to the back plate 2 through several connecting pieces, and the connecting pieces pass through the deflector set on the back of the transformer wall 1 3 is connected with the transformer surrounding wall 1, the coolant gap is formed between the back plate 2 and the transformer surrounding wall 1 through the connecting piece, and several temperature sensors 13 and flow sensor 14.

[0050] A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0051] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0052] The top view of the baffles 3 is in an inverted V shape, and the baffles are arranged in a staggered manner.

[0053] The d...

Embodiment 2

[0064] Embodiment 2: An early warning device for abnormal operation of substation equipment, including a transformer wall 1 whose back is connected to the back plate 2 through several connectors, and the connectors are guided through the back of the transformer wall 1 The board 3 is connected to the transformer surrounding wall 1, and the coolant gap is formed between the back plate 2 and the transformer surrounding wall 1 through the connecting piece, and several temperature sensors 13 are arranged on the surface of the back plate in the coolant gap with flow sensor 14.

[0065] A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0066] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0067] The top view of the baffles 3 is in an inverted V shape, and the baffles...

Embodiment 3

[0075] Embodiment 3, a warning device for abnormal operation of substation equipment, including a transformer surrounding wall 1 whose back is connected to the backboard 2 through several connecting parts, and the connecting parts pass through the deflector set on the front of the backboard 2 3 is connected to the back plate 2, and the coolant gap is formed between the back plate 2 and the transformer surrounding wall 1 through the connecting piece, and a number of temperature sensors 13 and flow rate sensors 13 are arranged on the surface of the back plate in the coolant gap. sensor 14.

[0076] A sealing plate 9 is arranged around the coolant gap, and a water inlet 6 and a water outlet 8 are respectively arranged at two parallel sealing plates 9 .

[0077] The deflector 3 is arranged at the water inlet 6 , and the top surface of the deflector 3 is not parallel to the water flow direction of the water inlet 6 .

[0078] The top view surface of the deflectors 3 is arc-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com