Mountainous region laborsaving line lifting device

A labor-saving, wire lifter technology, applied in the direction of overhead lines/cable equipment, can solve problems such as wasting effort, and achieve the effect of saving labor, simple structure and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

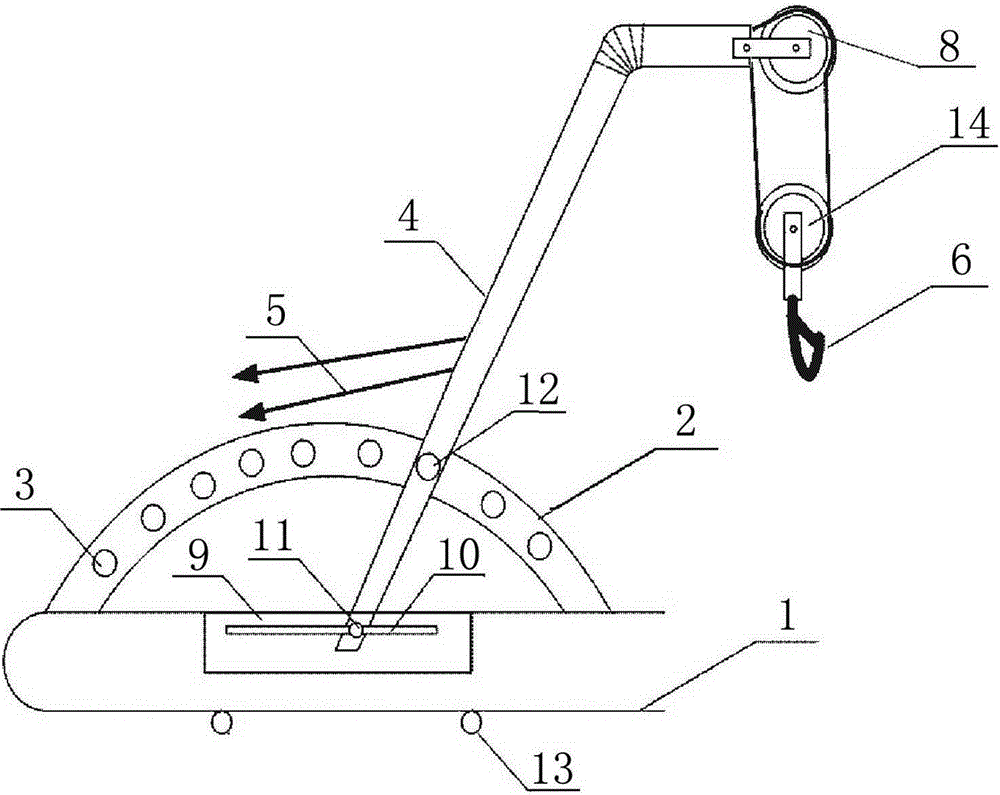

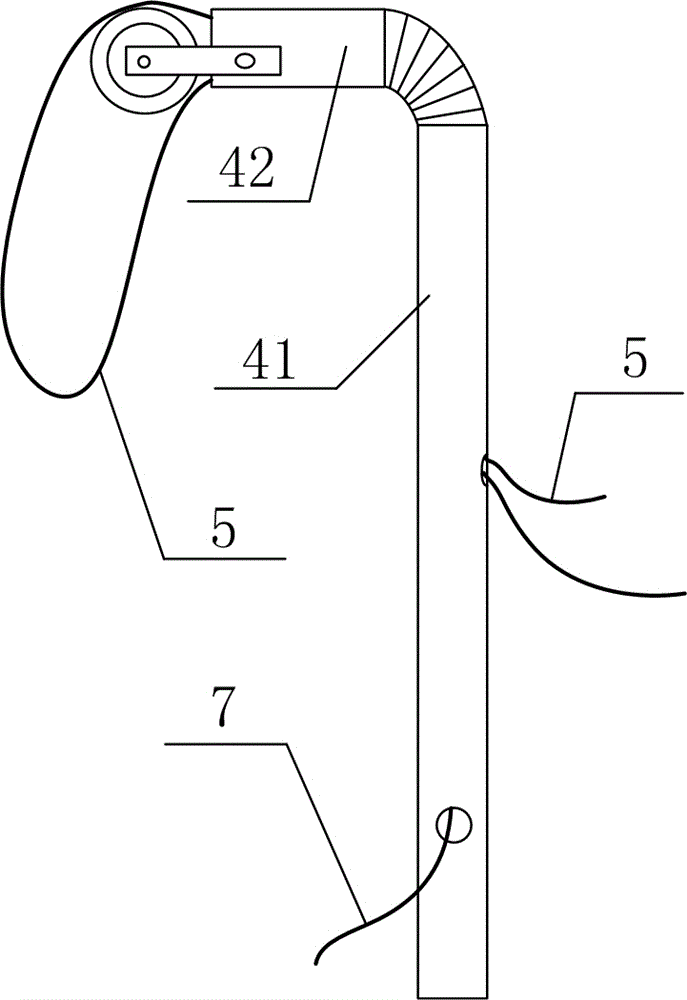

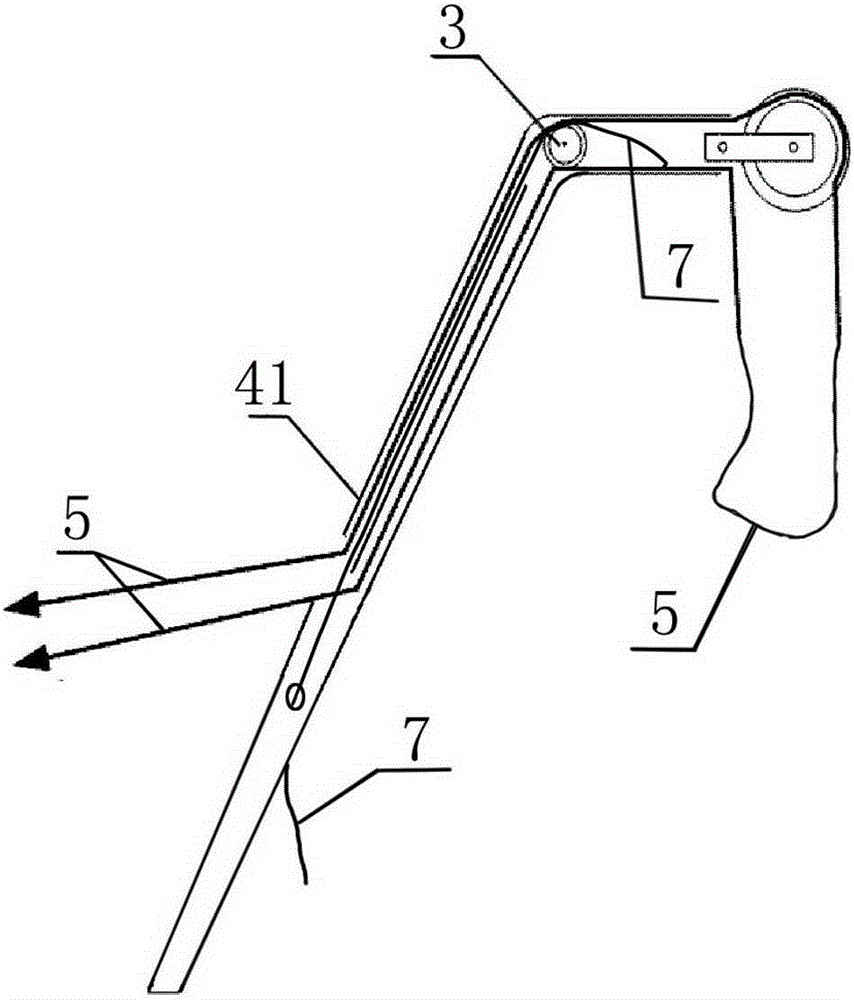

[0025] A labor-saving line lifter for mountains, such as Figure 1-Figure 3 As shown, it includes a U-shaped ring 1 for fixing to the cross arm of a utility pole, an adjusting hair plate 2 arranged on the U-shaped ring 1, an arc-shaped arrangement of adjusting holes 3 arranged on the adjusting ring 2, and one end The connecting rod 4 hinged on the U-shaped ring 1, the pulley block arranged on the connecting rod 4, the steel wire rope 5 arranged on the pulley block, the hook 6 suspended on one end of the steel wire rope 5, and the tight wire connected to the other end of the steel wire rope 5 The connecting rod 4 is composed of a main rod 41 whose one end is hinged on the U-shaped ring 1, and a mounting rod 42 whose one end is hinged on the other end of the main rod 41 and is used for the installation of the pulley block; the middle part of the adjustment hair plate 2 There is also a connecting rope 7 fixedly connected to it at one end, and the other end of the connecting rope ...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the structure of the pulley block. In this embodiment, the pulley block is composed of a movable pulley 14 and a fixed pulley 8, and the movable pulley 14 is suspended on one end of the wire rope 5 and used for The hook 6 is fixed; the fixed pulley 8 is fixedly installed on the installation rod 42 .

[0029] And the quantity of this fixed pulley 8 in the present embodiment is two, is respectively positioned at the two ends of mounting rod 42, and the fixed pulley 8 at the position adjacent to main rod 41 can also be used as the pulley that is convenient to connect rope 7 to move at the same time; A pulley on which the connecting rope 7 moves is mounted inside the mounting bar 42 adjacent to the fixed pulley 8 . In the present embodiment, the fixed pulley 8 adjacent to the position of the main rod 41 is used as a pulley to facilitate the movement of the connecting rope 7, as figur...

Embodiment 3

[0031] The difference between this embodiment and Embodiment 2 is that the connection mode between the main rod 41 and the U-shaped ring 1 is optimized in this embodiment, and the specific settings are as follows:

[0032] The main rod 41 is fixedly installed on the U-shaped ring 1 through the connecting plate 9, wherein the connecting plate 9 is provided with a transverse bar-shaped mounting hole 10, and the bottom of the main rod 41 is fixed on the bar through the first fixing bolt 11. On the shaped mounting hole 10, the rod body on the main rod 41 close to the adjusting dish 2 is fixed on the adjusting hole 3 by the third fixing bolt 12.

[0033] This embodiment also optimizes the connection relationship between the U-shaped ring 1 and the cross-arm of the utility pole at the same time. The U-shaped ring 1 described in this embodiment is fixed on the cross-arm of the utility pole by the second fixing bolt 13, as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com