Cable connector

A cable connector, conductive connection technology, used in cable connectors, cable terminals, multi-conductor connectors, etc., can solve the problems of easy corrosion, tip discharge, affecting service life, etc., to achieve flexible and convenient connection, reduce discharge opportunities, Strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

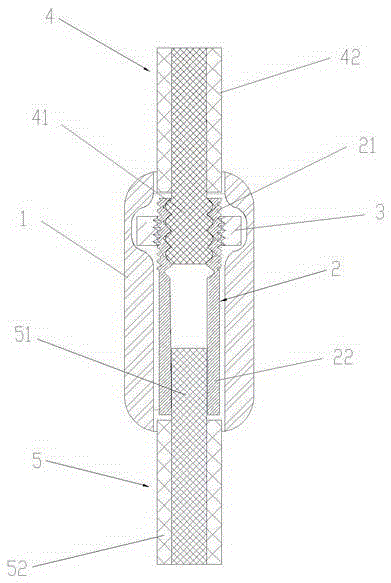

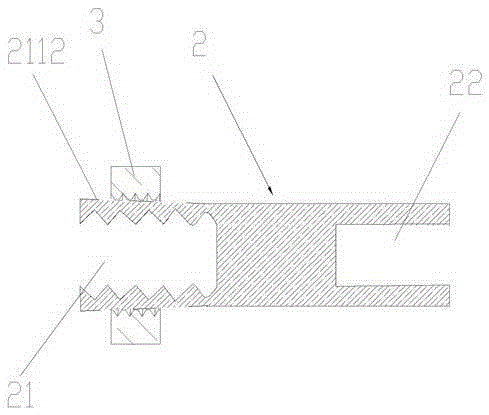

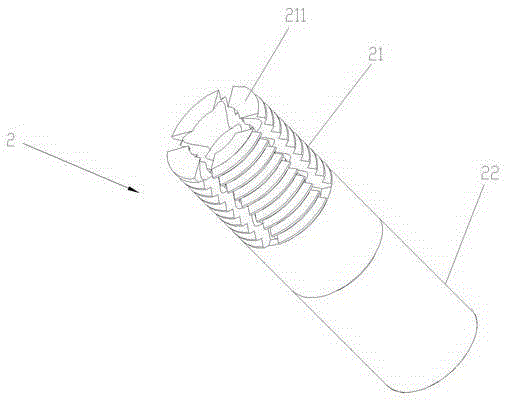

[0021] like Figures 1 to 3 As shown, in this embodiment, a cable connector includes an elastic insulating jacket 1, a conductive connector 2 and a locking member 3 sleeved on the conductive connector 2, the conductive connector 2 is a columnar structure, and the conductive connector 1 is two The first connection port 21 and the second connection port 22 are respectively opened at the end, the first connection port 21 is integrally formed by four locking pieces 211, and the second connection port 22 is a hollow tubular structure. It is sleeved on the outer circumference of the conductive connector 2 and the locking member 3 .

[0022] In this embodiment, the invention is applied to the connection between the fixed terminal 4 and the cable 5 of the electric box. During use, as figure 1 As shown, the elastic insulating sealing jacket 1 is inserted into the cable 5 first, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com