A Permanent Magnet Motor with Reduced Pole Frequency and Slot Frequency Radial Electromagnetic Exciting Force

A technology of electromagnetic excitation force and permanent magnet motor, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, and the shape/style/structure of the magnetic circuit. and power density, the effect of the chute is not obvious, etc., to achieve the effect of reducing vibration and noise, reducing mechanical vibration and noise, reducing deformation and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

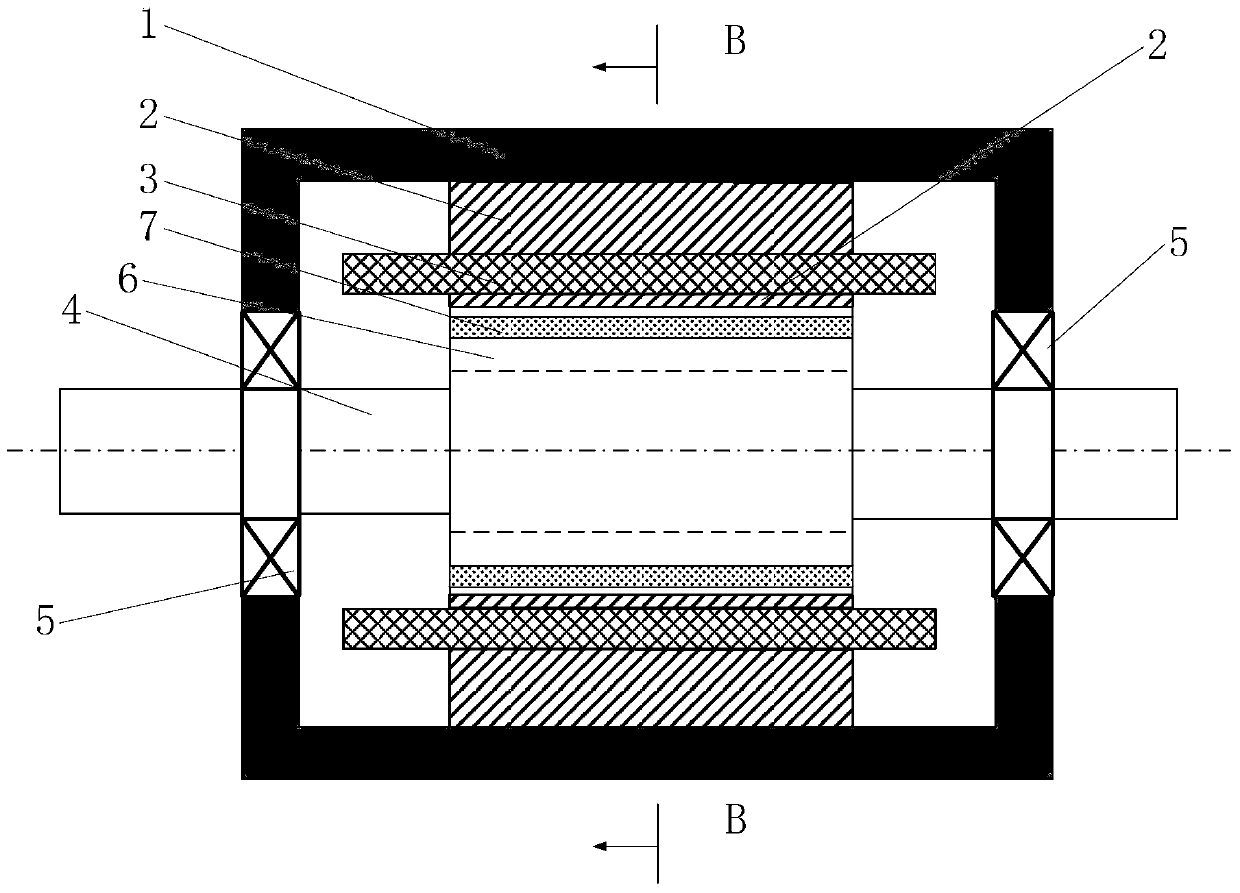

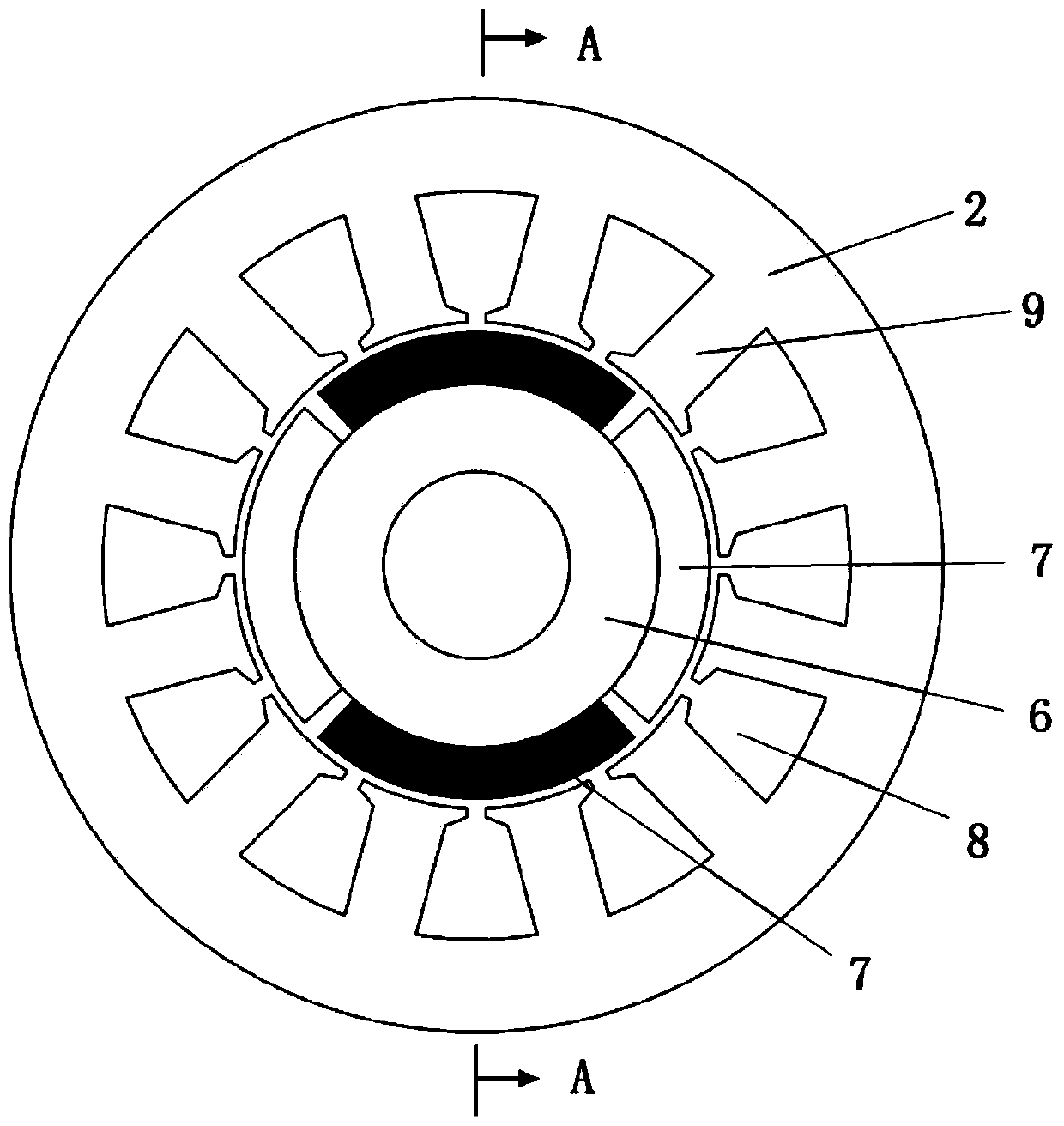

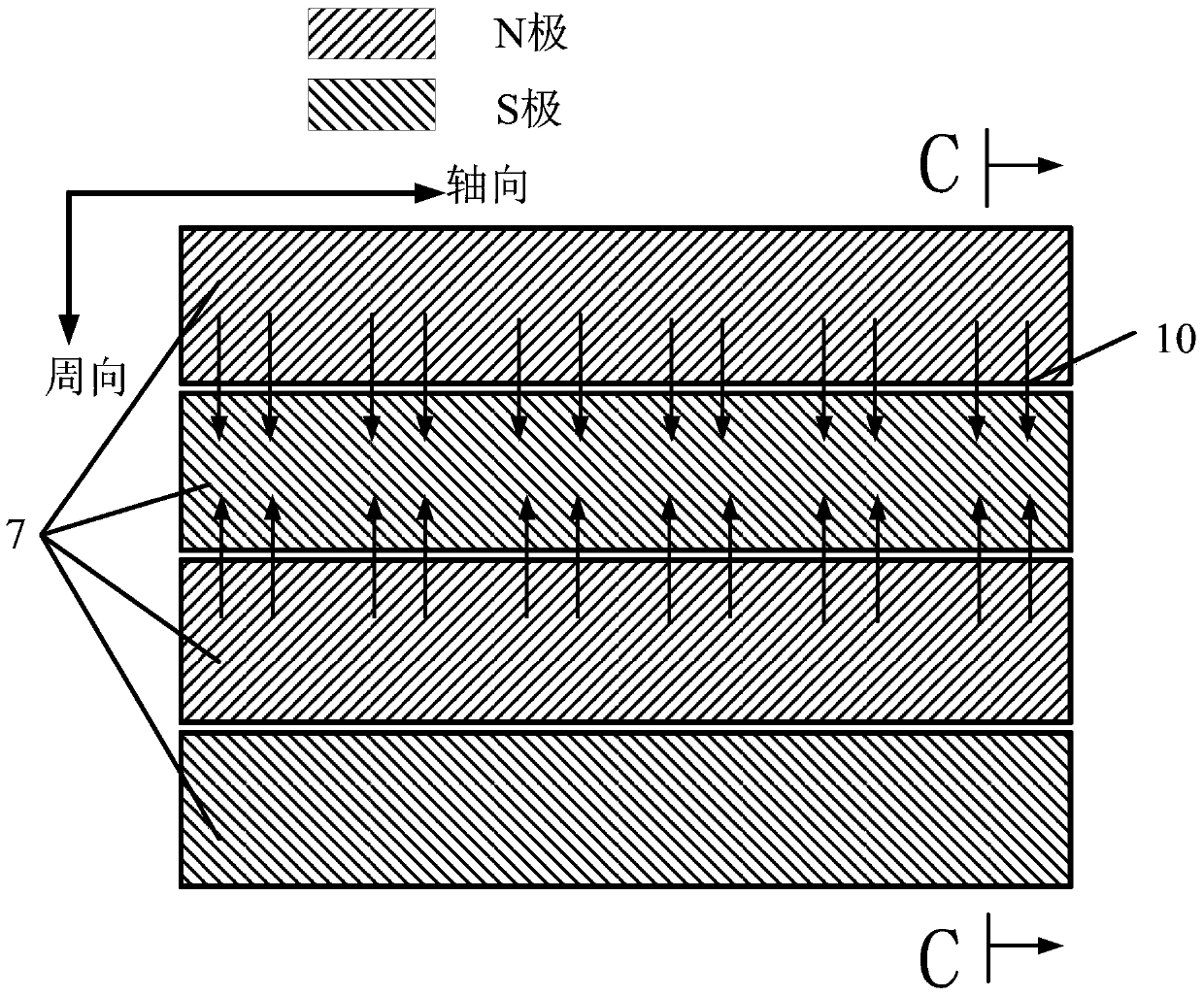

[0026] Such as Figure 1 ~ Figure 3 As shown, the permanent magnet motor includes a stator base 1 , a stator core 2 , a stator winding 3 , a permanent magnet 7 , a rotor core 6 , a rotor shaft 4 and a bearing 5 . A stator core 2 is fixed inside the stator frame 1, and a stator winding 3 is arranged on the stator core 2; wherein, the stator frame 1 can be fixed by a conventional motor installation method, and the stator core 2 is a part of the magnetic circuit of the motor , The stator winding 3 is generally a three-phase winding. The rotor shaft 4 is fixedly arranged in the stator frame 1 through the bearing 5, and the rotor core 6 is fixedly arranged on the rotor shaft 4, and a permanent magnet 7 is arranged on the rotor iron core 6, and the magnetization direction of the permanent magnet 7 is radial, The polarities of the permanent magnets 7 are alternately arranged, and the rotor shaft 4 can drive the rotor core 6 and the permanent magnets 7 to rotate around the axis. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com