An asynchronous motor with co- and oppositely energized windings in axially adjacent segments

An asynchronous motor, axial technology, applied to asynchronous induction motors, the shape/style/structure of winding conductors, electrical components, etc., can solve the problems of motor vibration and noise, and achieve the elimination of slot frequency radial electromagnetic excitation. force, reducing deformation and vibration, reducing the effect of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

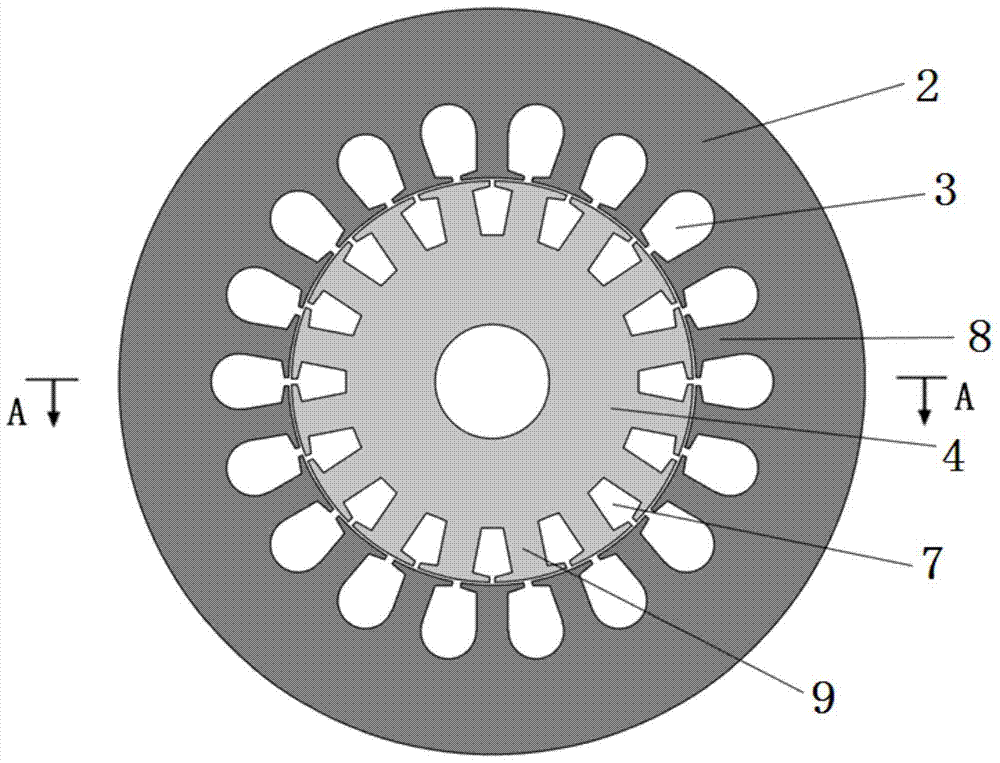

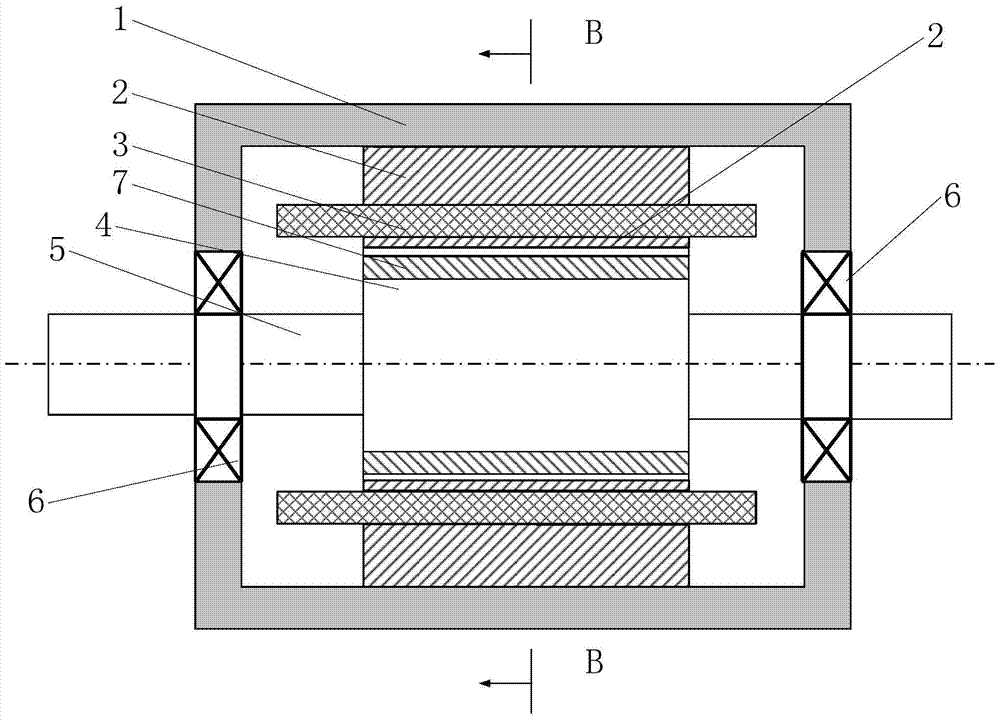

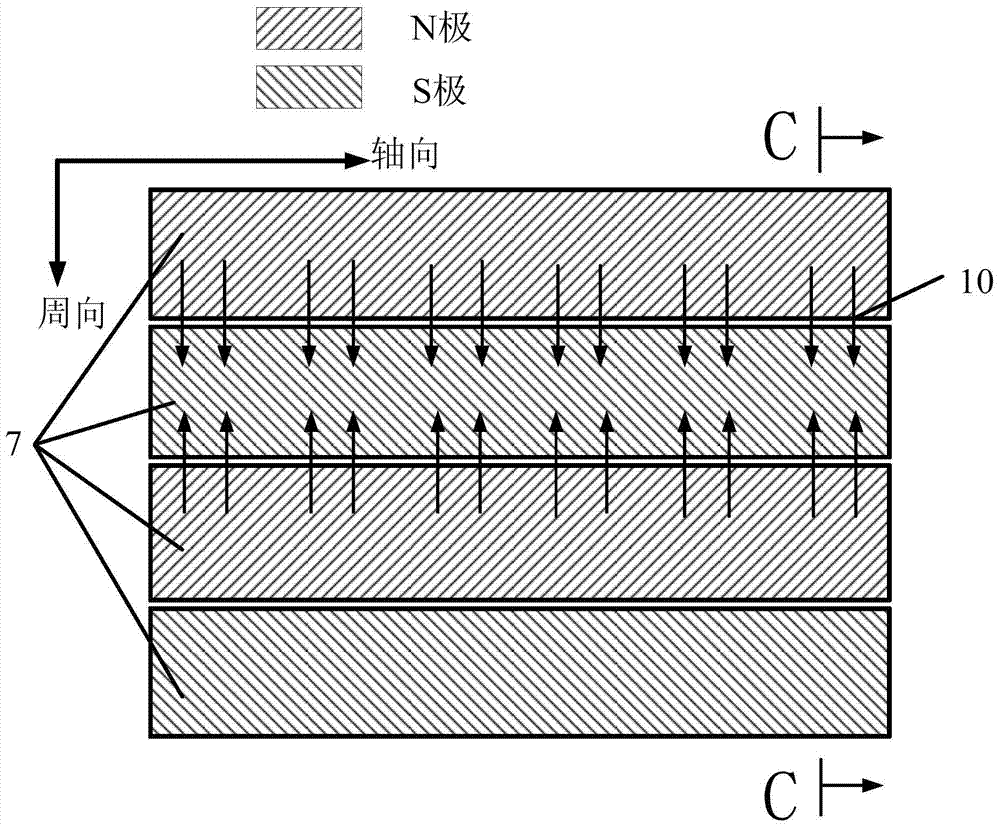

[0025] Such as figure 1 , figure 2 As shown, the existing asynchronous motor includes a stator frame 1, a stator core 2, a stator winding 3, a rotor core 4, a rotor shaft 5, a bearing 6 and a rotor squirrel cage winding 7; wherein, the stator frame 1 can adopt conventional The installation method of the motor is fixed, and the stator core 2 is a part of the magnetic circuit of the motor. A stator iron core 2 is fixedly arranged in the stator base 1 , and the inner circle of the stator iron core 2 is provided with grooves to form stator teeth 8 ; the stator winding 3 is fixedly arranged between the stator teeth 8 of the stator iron core 2 . The rotor core 4 is fixed on the rotor shaft 5, the rotor shaft 5 can drive the rotor core 4 to rotate around the axis, the rotor shaft 5 is fixed in the stator frame 1 through the bearing 6, and the outer circumference of the rotor core 4 is uniform Several slots are provided, and the slots are distributed between the rotor teeth 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com