Suction hose fitting

A technology of hoses and fittings, applied in the direction of engine components, valve casing structure, cleaning method using liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

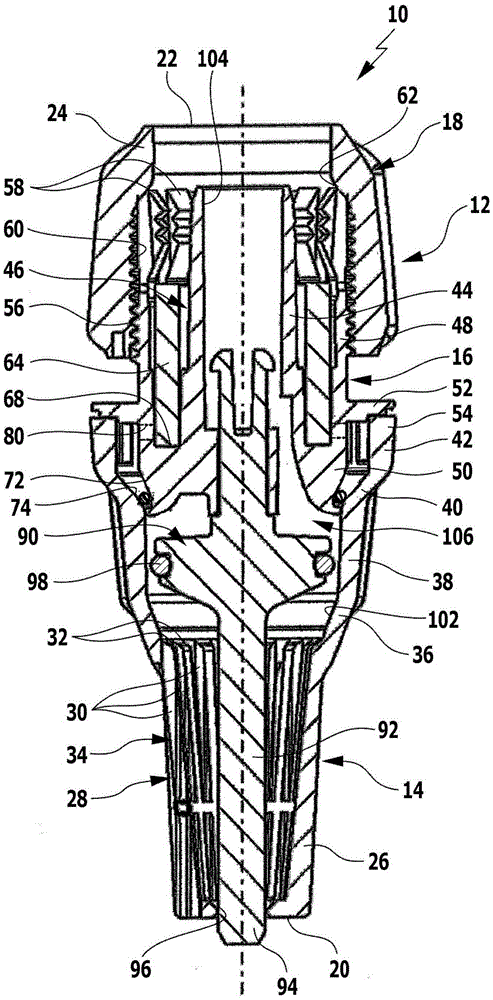

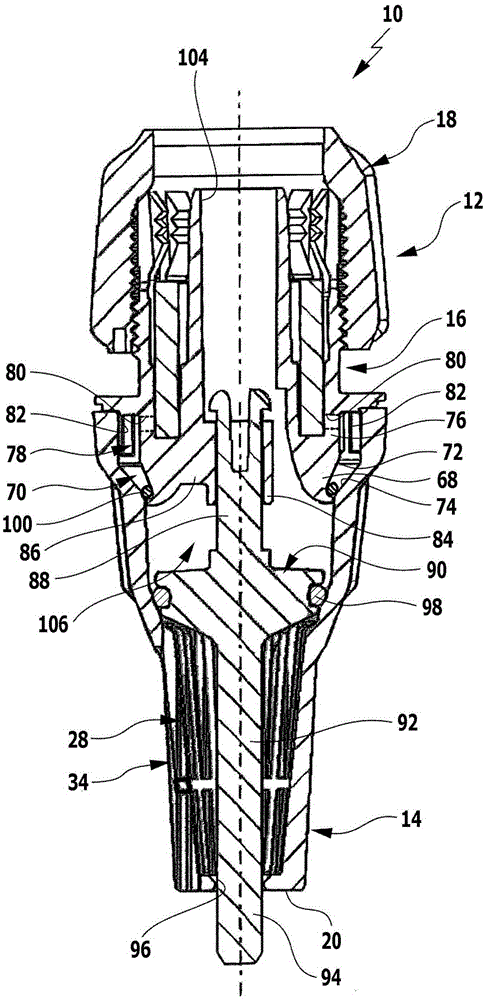

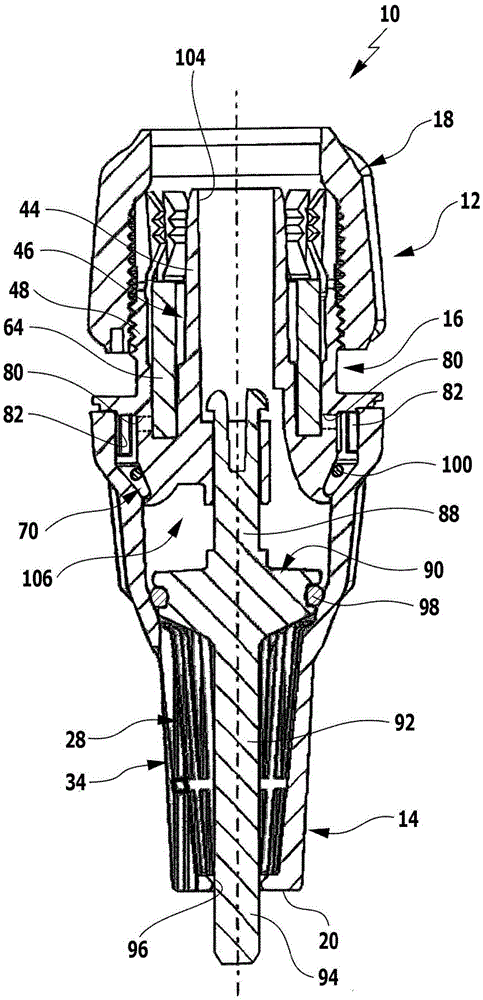

[0039] An advantageous embodiment of a suction hose fitting according to the invention, generally designated 10 , is shown schematically in the drawing. The suction hose fitting 10 has a housing 12 with a first housing part 14 , a second housing part 16 and a third housing part 18 . The first housing part 14 forms the front side 20 of the housing 12 and the second housing part 16 forms the rear side 22 of the housing 12 . The third housing part 18 can be screwed onto the second housing part 16 and protrudes with a rear end section 24 beyond the rear side 22 of the housing 12 .

[0040] The first housing part 14 forms a filter device in the form of a filter cage 28 with a plurality of housing openings 30 with a front housing section 26 adjoining the front side 20 , which housing openings are respectively located on two sides. Adjacent partitions 32 extend between them. The housing opening 30 forms overall an inlet opening 34 of the housing 12 .

[0041] Via a first conical w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com