An energy harvester for converting vibrational motion of a vibrating equipment into electrical energy, and a device for monitoring the operation of a vibrating equipment

A technology of energy harvester and vibration equipment, which is applied in the direction of electromechanical devices, mechanical equipment, mechanisms that generate mechanical power, etc., and can solve the problems that the energy harvester is not designed to supply a large amount of power, high acceleration, and the energy harvester cannot bear it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

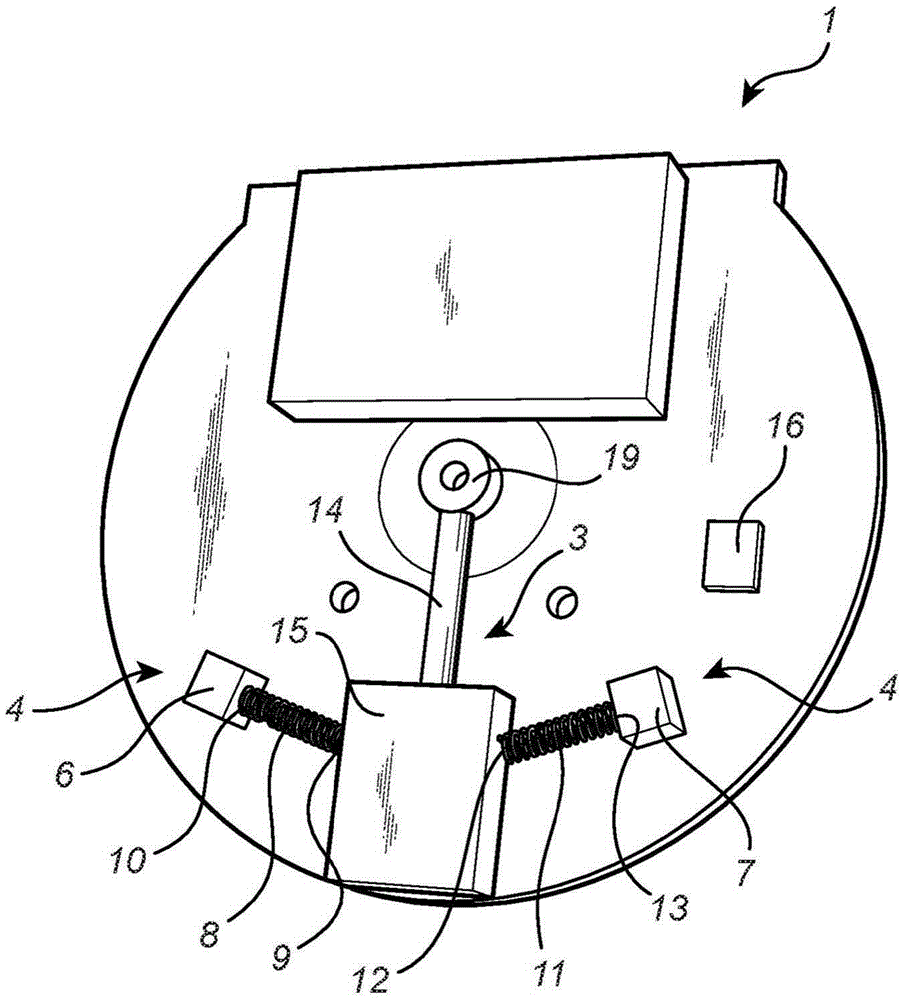

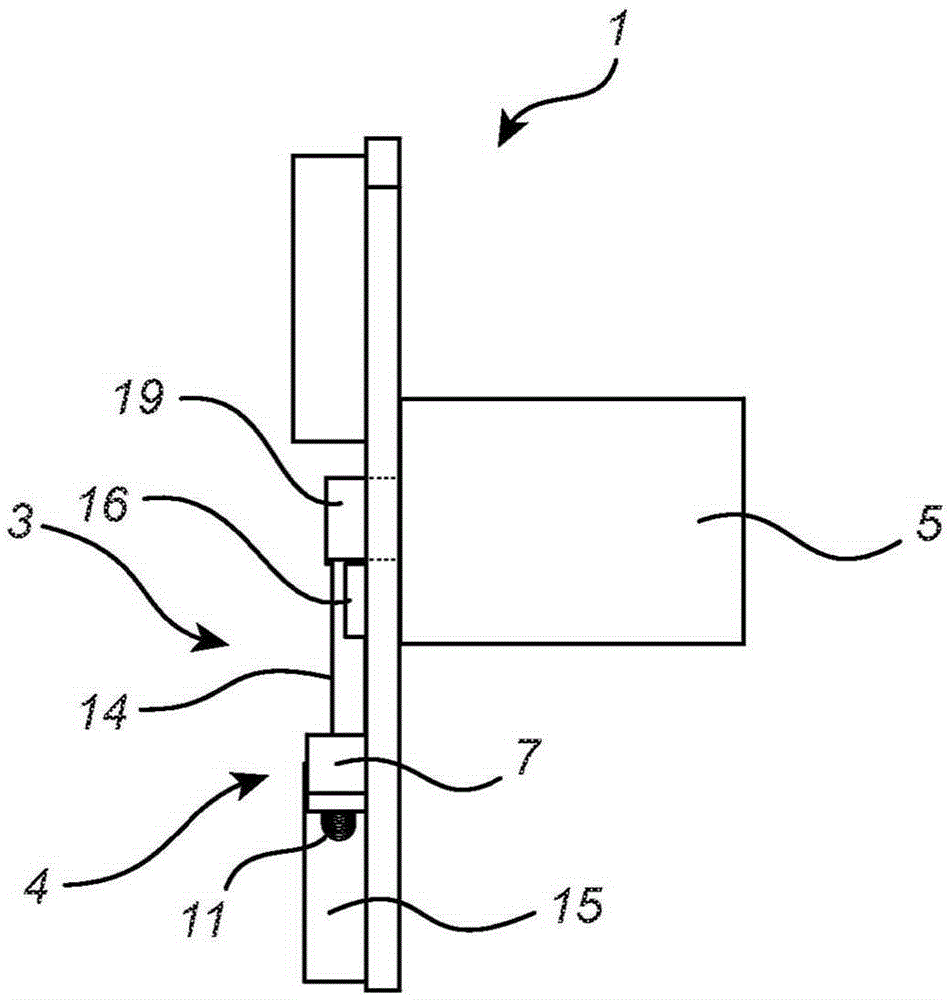

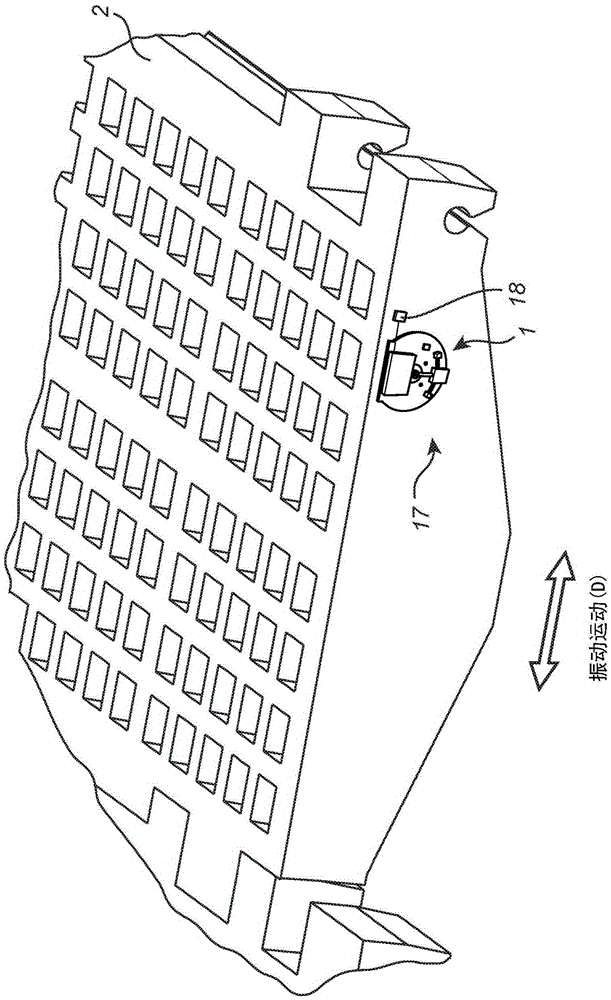

[0028] Figure 1a Shown will vibrate device 2 (see figure 2 An exemplary embodiment of an energy harvester 1 that converts vibratory motion of ) into electrical energy. The energy harvester 1 comprises a pendulum 3 pivotably attached to a vibration device 2, a motion limiter 4 arranged to limit the pivotal movement of the pendulum 3 during movement of the vibration device 2, and a generator connected to the pendulum 3 5 (see Figure 1b ). A generator 5 is arranged to convert the pivotal movement of the pendulum 3 into electrical energy. The oscillating motion of the oscillating device 2 has an operating frequency, and the pendulum 3 has a natural frequency different from the operating frequency of the oscillating device 2 . The movement limiter 4 consists of a first blocking element 6 arranged on one side of the pendulum 3 and a second blocking element 7 arranged on the other side of the pendulum 3 . The energy harvester 1 has a first spring element 8 with a first end 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com