Method and assembly for measuring a gas temperature distribution in a combustion chamber

A technology of gas temperature distribution and temperature distribution, applied in the direction of sensing radiation from gas/flame, measuring device, optical radiation measurement, etc., to achieve the effect of optimizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

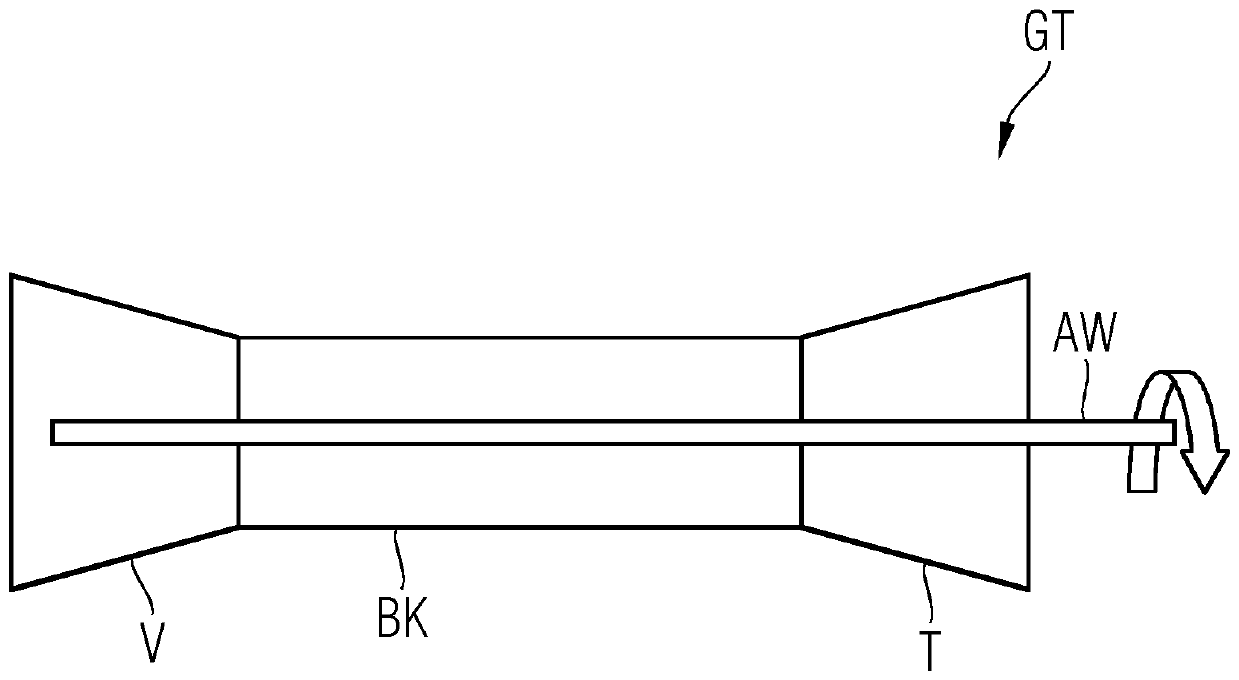

[0026] figure 1 As an application example of the invention, a gas turbine GT is shown in the schematic diagram with a combustion chamber BK in which it is necessary to measure the gas temperature distribution during operation. The gas turbine GT has a compressor V for compressing incoming air, a combustor BK for combusting delivered fuel, and a turbine T for converting heat and kinetic energy generated by combustion into rotational energy. Rotational energy is also transmitted via the drive shaft AW to the compressor V in order to drive it.

[0027] Furthermore, the invention is also used for measuring the gas temperature distribution in the combustion chamber of an internal combustion engine, a jet propulsion plant or other internal combustion engines.

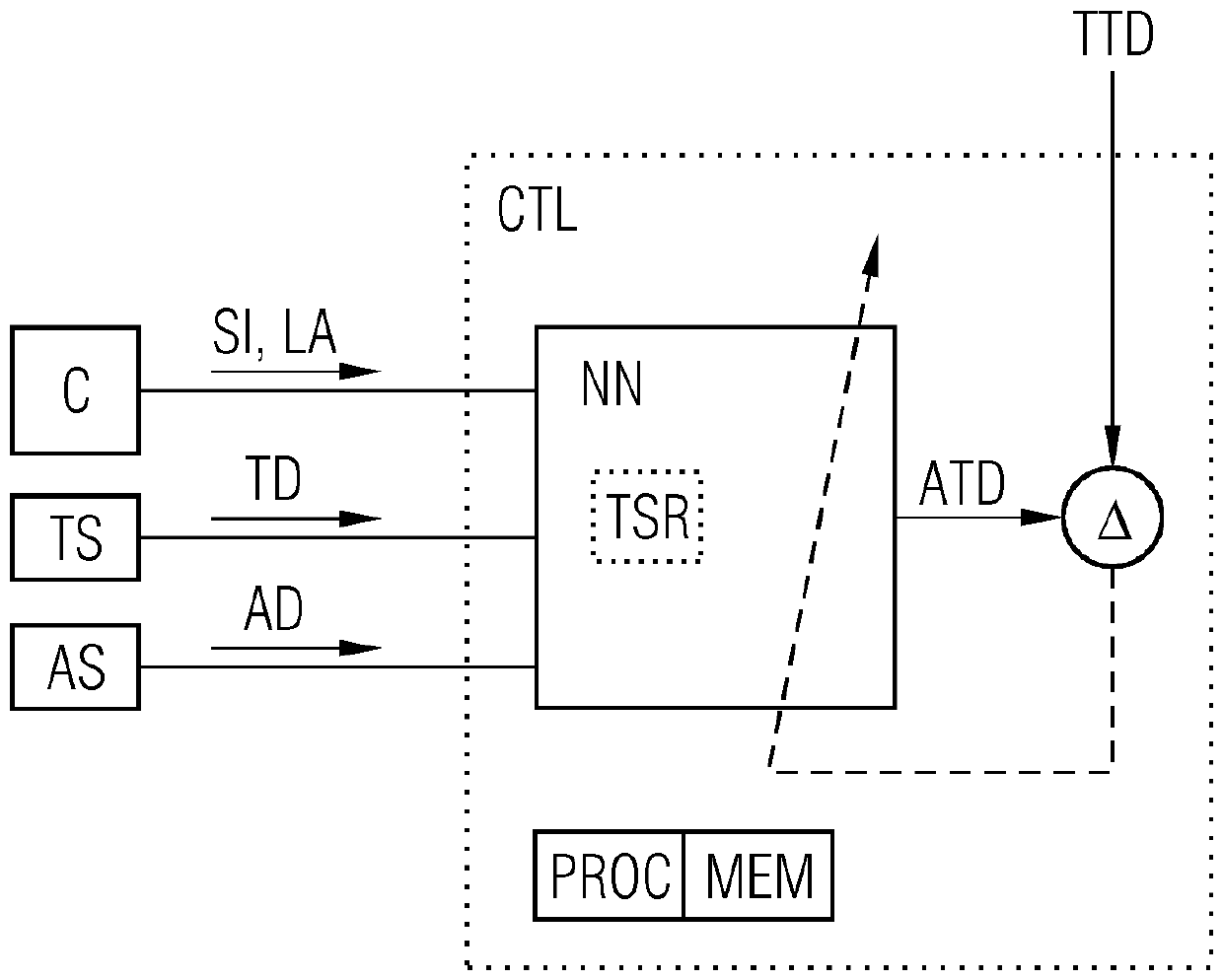

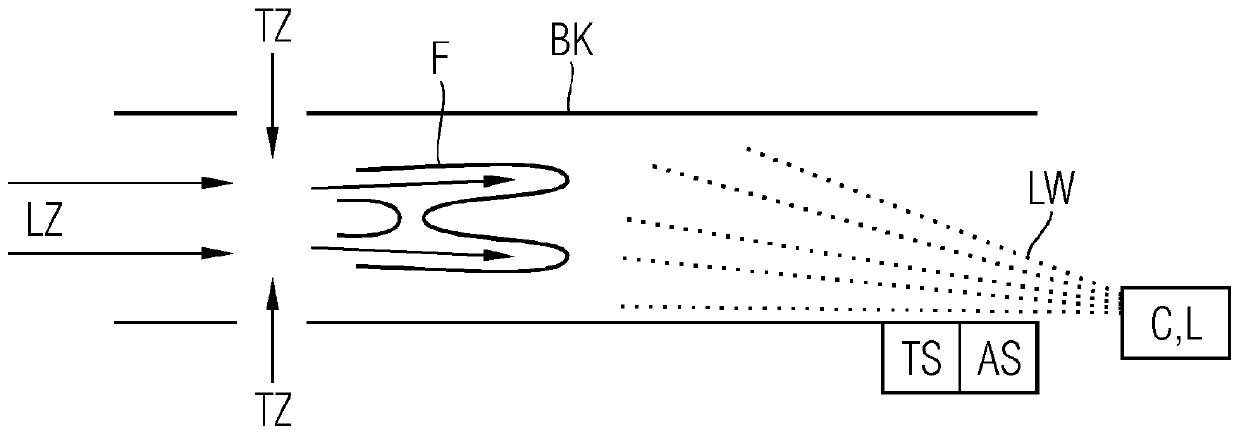

[0028] figure 2 The schematic diagram shows a tubular combustion chamber BK with an optical sensor C for measuring the gas temperature distribution in the combustion chamber BK. The combustion chamber BK can be, in partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com