A new type of straw crushing and returning machine

A new type of straw crushing technology, applied in the field of agricultural machinery, can solve the problems that the use effect cannot fully meet the agronomic requirements, the crushing parts cannot be arranged, the straw is not uniformly scattered, etc., and the effect of reasonable design, thorough crushing and good effect can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

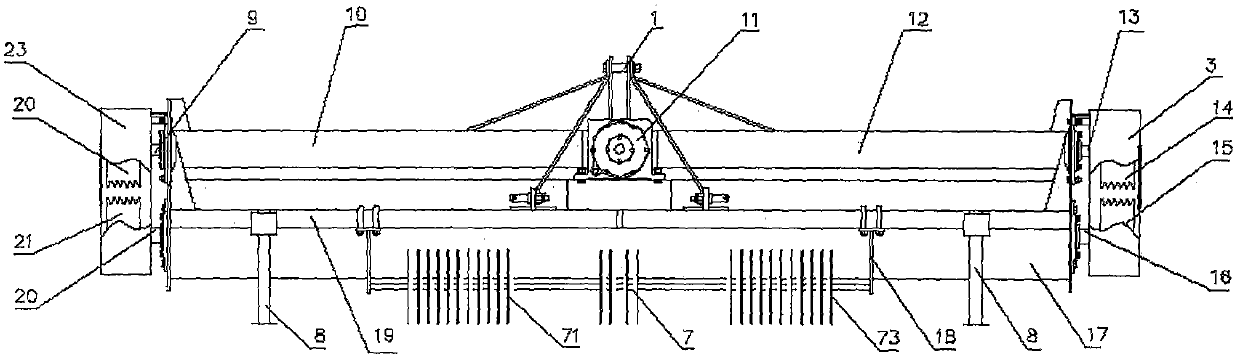

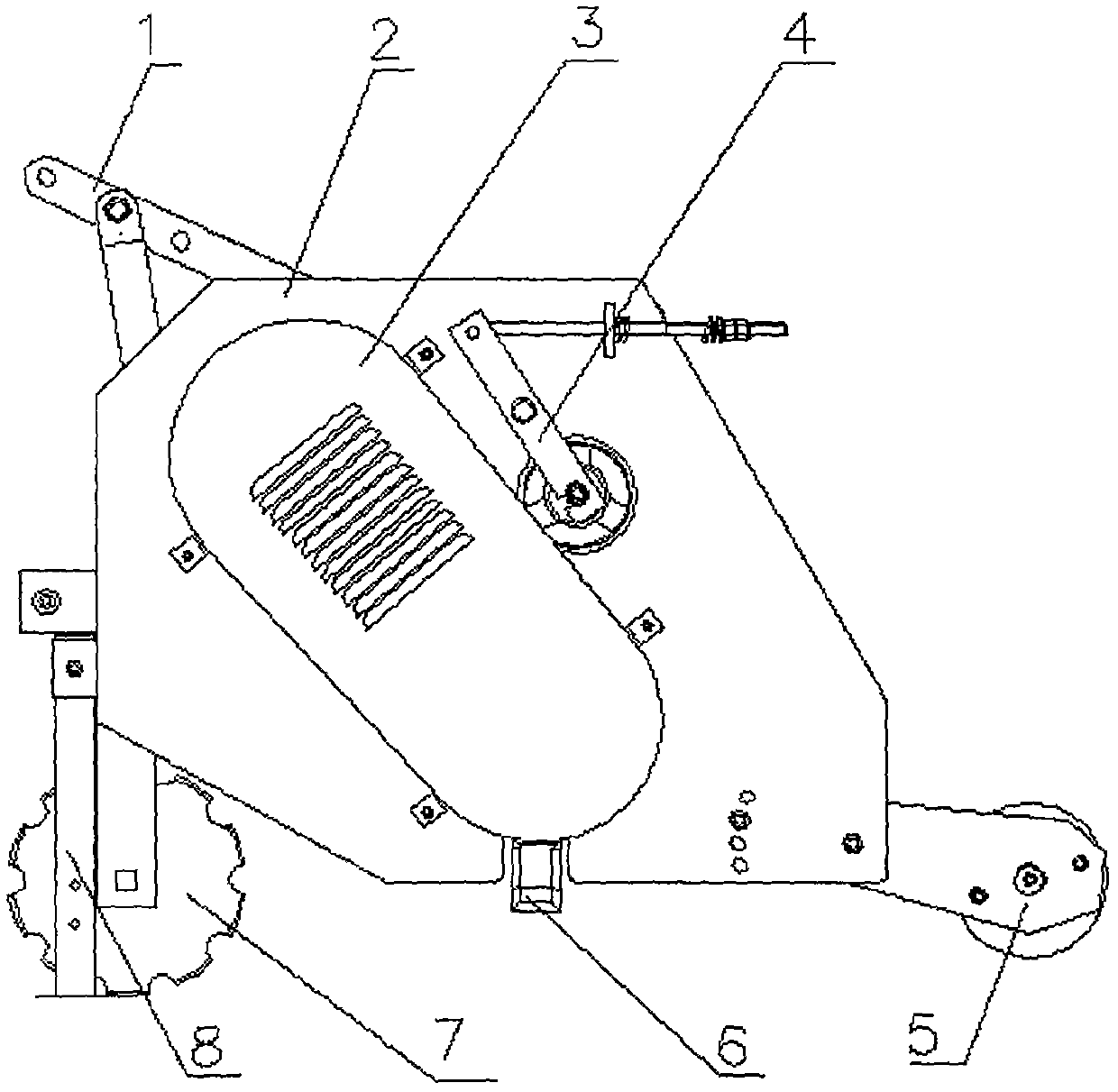

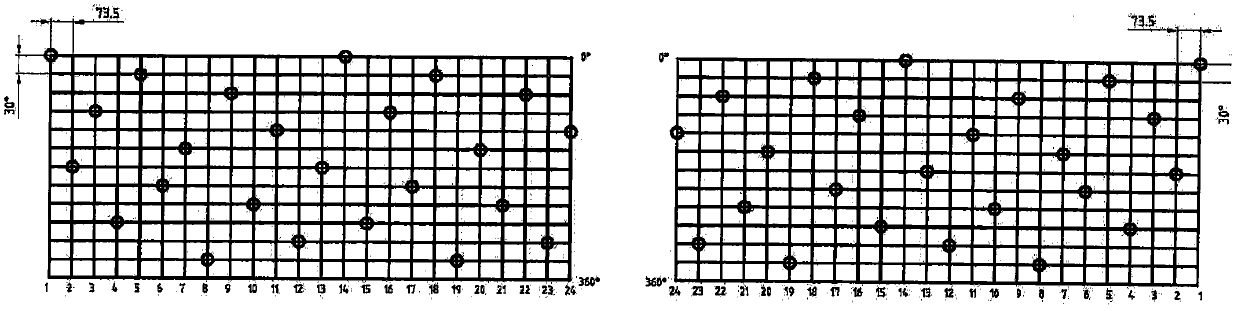

[0019] like figure 1 , 2 , 3, 4, 5

[0020] A new type of straw crushing and returning machine, including a hanging frame 1, a hood 2, a side plate of a cutter shaft, a tensioning wheel 4, a box assembly 11 and a supporting foot 8, the tensioning wheel 4 can be adjusted at any time according to needs, and the overall machine adopts The left and right are completely symmetrical. The left end of the box assembly 11 is connected with the second left shaft 13, the right end of the box assembly 11 is connected with the second right shaft 9, and the other end of the second left shaft 13 is connected with the driving pulley 14. The other end of the right second shaft 9 is connected with the driving pulley 22, the driving pulley is connected with the passive pulley respectively through the belt, the passive pulley is respectively connected with the left knife shaft 16 and the right knife shaft 20, and the left knife shaft 16 is connected with the driven pulley respectively. The conn...

Embodiment 2

[0022] like figure 1 , 2 , 3, 4, 5

[0023] A new type of straw crushing and returning machine, including a hanging frame 1, a hood 2, a side plate of a cutter shaft, a tensioning wheel 4, a box assembly 11 and a supporting foot 8, the tensioning wheel 4 can be adjusted at any time according to needs, and the overall machine adopts The left and right are completely symmetrical. The left end of the box assembly 11 is connected with the second left shaft 13, the right end of the box assembly 11 is connected with the second right shaft 9, and the other end of the second left shaft 13 is connected with the driving pulley 14. The other end of the right second shaft 9 is connected with the driving pulley 22, the driving pulley is connected with the passive pulley respectively through the belt, the passive pulley is respectively connected with the left knife shaft 16 and the right knife shaft 20, and the left knife shaft 16 is connected with the driven pulley respectively. The conn...

Embodiment 3

[0025] like figure 1 , 2 , 3, 4, 5

[0026] A new type of straw crushing and returning machine, including a hanging frame 1, a hood 2, a side plate of a cutter shaft, a tensioning wheel 4, a box assembly 11 and a supporting foot 8, the tensioning wheel 4 can be adjusted at any time according to needs, and the overall machine adopts The left and right are completely symmetrical. The left end of the box assembly 11 is connected with the second left shaft 13, the right end of the box assembly 11 is connected with the second right shaft 9, and the other end of the second left shaft 13 is connected with the driving pulley 14. The other end of the right second shaft 9 is connected with the driving pulley 22, the driving pulley is connected with the passive pulley respectively through the belt, the passive pulley is respectively connected with the left knife shaft 16 and the right knife shaft 20, and the left knife shaft 16 is connected with the driven pulley respectively. The conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com