Method for making Tibetan tea with particle flavor

A production method and granule technology are applied in the production field of granulated flavor Tibetan tea, which can solve the problems of inconvenient brewing, easy turbidity of tea soup, single fragrance, etc., and achieve the effects of convenient brewing, clear and red tea soup, and unique fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

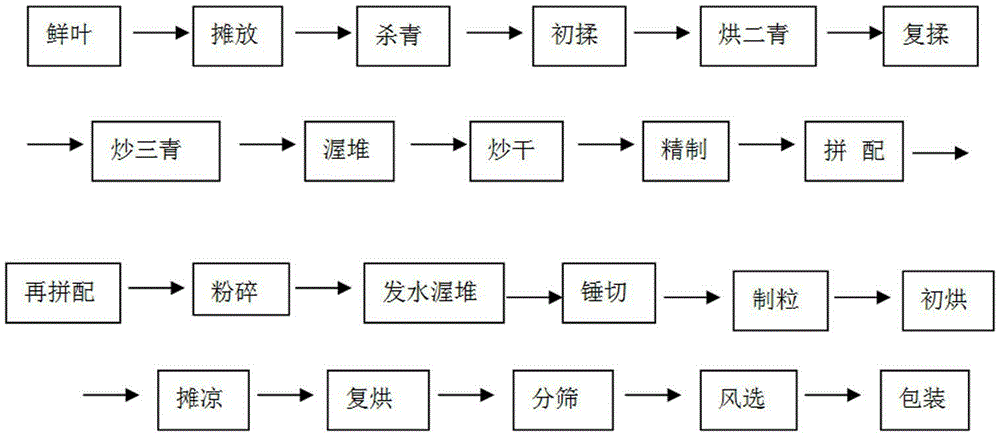

[0033] The preparation method of the granular flavored Tibetan tea of this example is to use the fresh leaves of tea leaves as raw materials, and process the granular flavored Tibetan tea through the following steps:

[0034] The fresh leaves of tea are spread, greened, first kneaded, secondly baked, re-kneaded, fried three greens, stacked, fried and dried, refined, blended, re-blended, crushed Process, steaming and stacking process, hammer cutting process, granulation process, initial drying process, cooling process, re-drying process, sieving process, winnowing process and packaging process to obtain the finished product of granule-flavored Tibetan tea, among which, blending The process is: blending the blended leaves obtained in the blending process with the fragrance ingredients to obtain the re-blended ingredients; in terms of weight, the ratio of the blended ingredients is: the fragrance ingredients are 5% of the re-blended ingredients; the fragrance ingredients are ros...

Embodiment 2

[0056] The preparation method of the granular flavored Tibetan tea of this example is to use Tibetan tea loose tea as raw material, and process the granular flavored Tibetan tea through the following steps:

[0057] Tibetan tea loose tea is obtained through re-combining batching process, crushing process, steaming and stacking process, hammer cutting process, granulation process, initial drying process, cooling process, re-drying process, sieving process, winnowing process and packaging process. Finished product of granular flavored Tibetan tea.

[0058] The re-mixing ingredients process is: blending Tibetan tea loose tea with flavor ingredients to obtain the re-mix ingredients; in terms of weight, the proportion of the ingredients is: the fragrance ingredients are 5% of the re-mix ingredients; the fragrance ingredients are rosemary, and the rosemary is obtained. Rosemary-type granule-flavored Tibetan tea.

[0059] All the other procedures are with embodiment one.

Embodiment 3

[0061] The preparation method of the granular flavor Tibetan tea of this example, except that the fragrance ingredients are 8% of the ingredients again by weight, all the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com