Pipe expanding device

A tube expander and tube expander technology, which is applied in the field of tube expanders, can solve the problems of complex structure, many waste products, and low yield of the tube expander, and achieve the effects of simple structure, convenient use, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

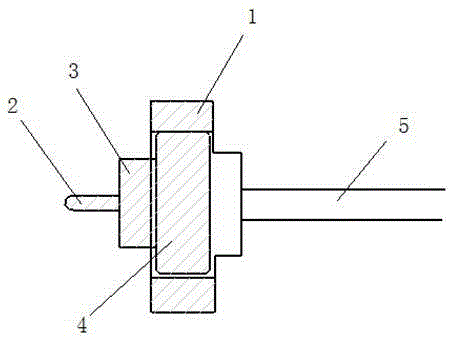

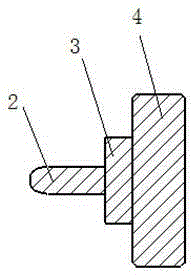

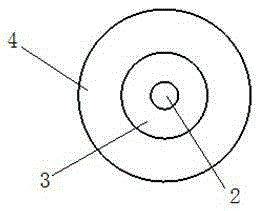

[0022] Embodiment, a kind of expansion device, see figure 1 , figure 2 with image 3 , including a mold base 1 and an expander core 2, the mold base 1 includes a cavity with one end closed and one end open and connected to the bearing 5, the expander core 2 is inserted into the cavity of the mold base 1 through the core base.

[0023] One end of the bearing 5 is connected with the closed end of the mold base 1, and the other end is connected with the driving device.

[0024] The core base is stepped, including a first step 4 and a second step 3, the first step 4 is inserted in the cavity of the mold base 1, the second step 3 is inserted in the cavity of the first step 4, and the expansion tube The core head 1 is inserted into the cavity of the second step 3 . The diameter of the first step 4 is greater than the diameter of the second step 3 .

[0025] The head of the expander core head 2 is arc-shaped.

[0026] In this embodiment, the length of the expansion core head 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com