Arc end tooth grinding clamp

A technology of arc-end teeth and fixtures, which is applied to gear teeth, gear cutting machines, manufacturing tools, etc., and can solve problems such as high cost, complicated process, and difficult realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

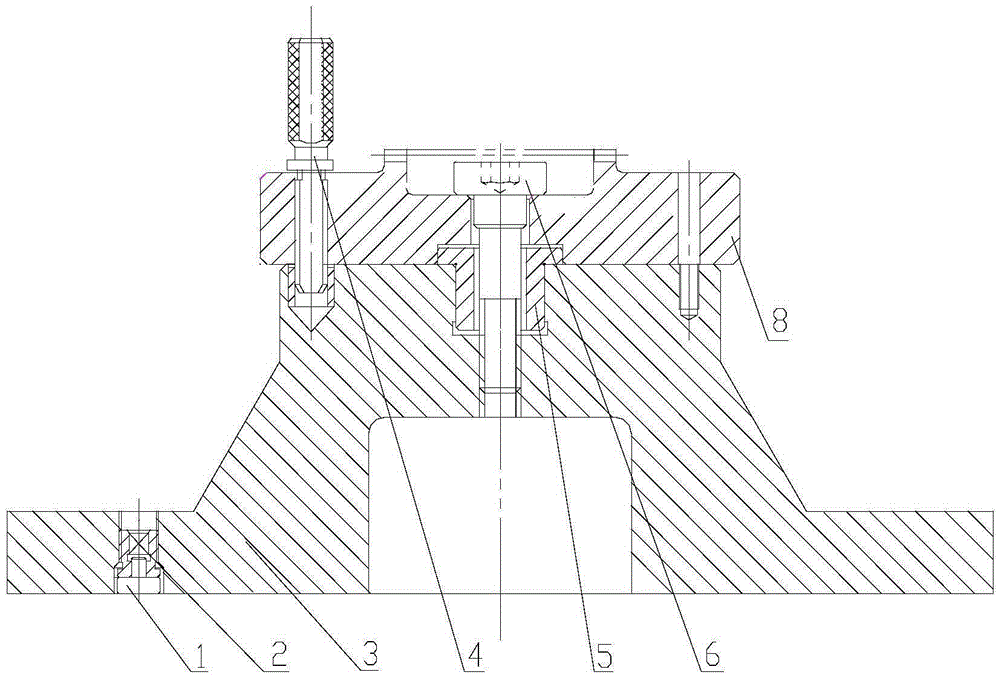

[0007] As shown in the figure, the arc-end tooth grinding fixture includes a clamp body 3, a positioning sleeve 5, a compression screw 6, an orientation pin 4, and an adjustment screw 2. A hole is arranged at the center of the clamp body 3, and the hole The upper end is provided with a step, and the lower end is provided with a screw thread, and the lower part of the positioning sleeve 5 is fitted on the step at the upper end of the hole, and the upper part of the positioning sleeve 5 can be fitted on the notch of the part 8 to be processed; the compression screw 6 passes through After the center hole of the part 8 to be processed and the positioning sleeve 5, install it on the thread at the lower part of the center hole of the clamp body 3, and press the part 8 to be processed; Orientation holes are arranged at the positions of the parts to be processed, and the orientation pins 4 are respectively matched with the angular holes and the orientation holes after being inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com