Hobbing cutter seat and key pin combined positioning structure for raise boring machine

A combined positioning and raise drilling rig technology, applied in the direction of drill bits, key connections, connecting components, etc., can solve the problems of low service life, high maintenance cost, swing and rotation of the hob seat, etc., to ensure service life and easy processing and manufacturing , Improve the effect of interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

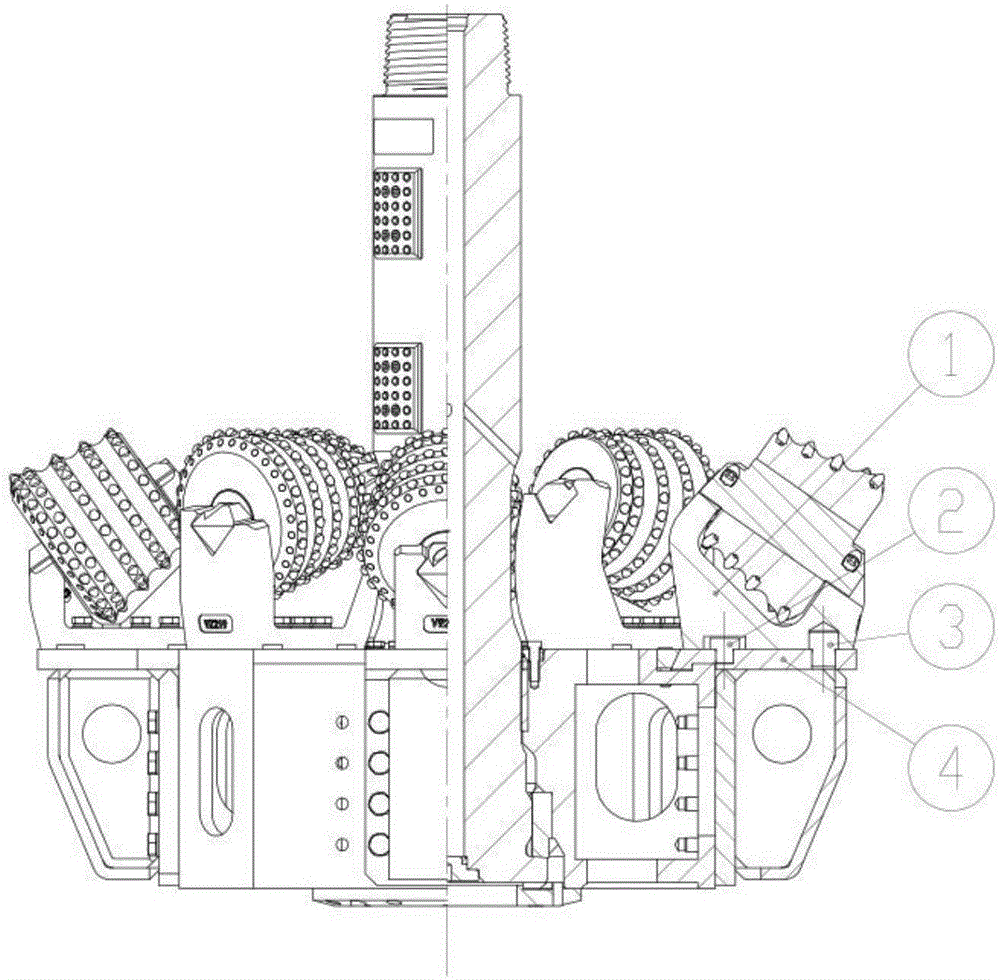

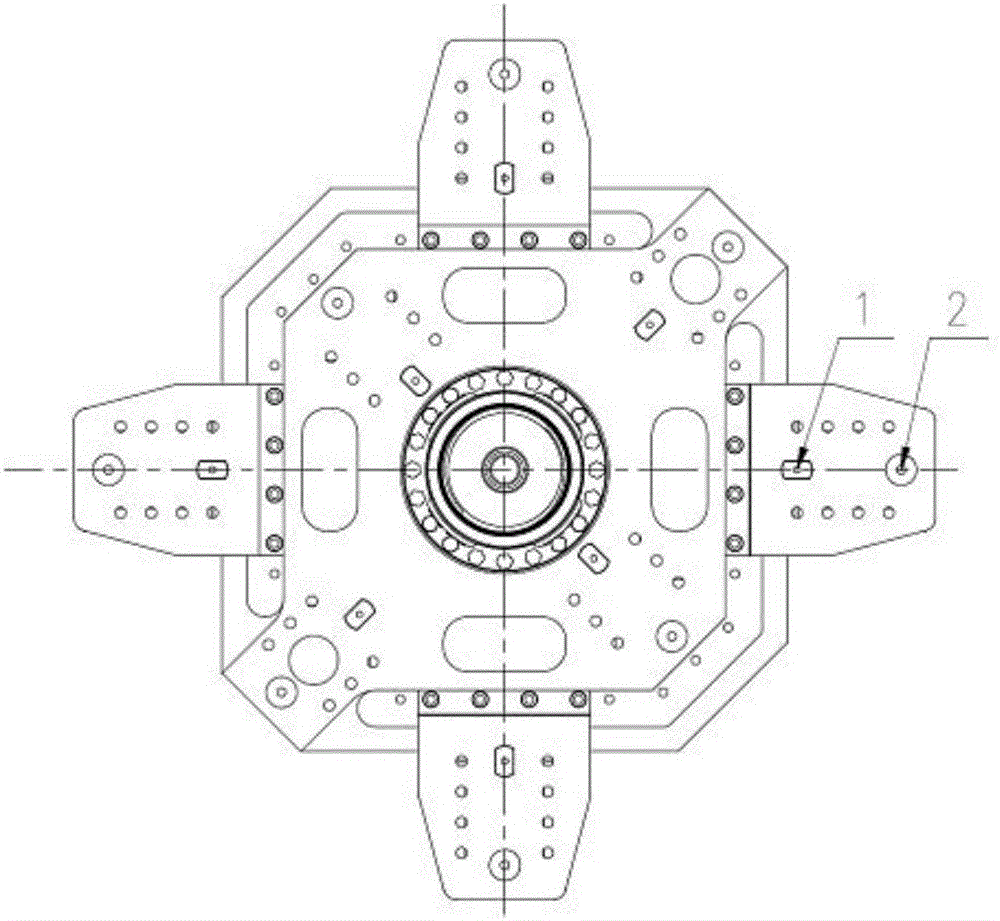

[0024] like figure 1 , 2 As shown, the present invention provides a hob block key pin combination positioning structure for a patio drilling rig. The hob block 3 is positioned and connected to the cutterhead tool holder 4 through several sets of positioning keys 1 and positioning pins 2. The upper end of the positioning key 1 The size is greater than the size of the lower end of the positioning key 1, the upper end of the positioning key 1 is transitionally connected with the hob seat 3, and the lower end of the positioning key 1 is in interference connection with the cutterhead tool holder 4; The size of the upper end of the positioning pin 2 is greater than the size of the lower end of the positioning pin 2, the upper end of the positioning pin 2 is transitionally connected with the hob seat 3, and the lower end of the positioning pin 2 interferes with the cutter head and tool holder 4 connect.

[0025] The present invention connects the hob seat 3 with the cutter head hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com