New energy passenger car frame welding clamp

A frame welding and new energy technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to adjust in real time, unsatisfactory, and affect welding efficiency, and achieve convenient, fast and economical real-time adjustment Labor cost, effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

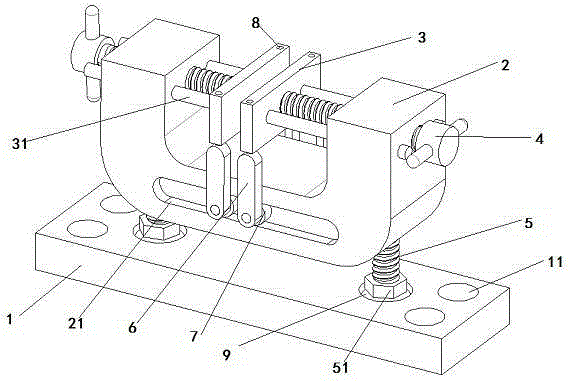

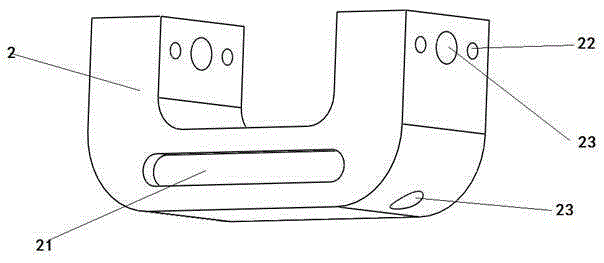

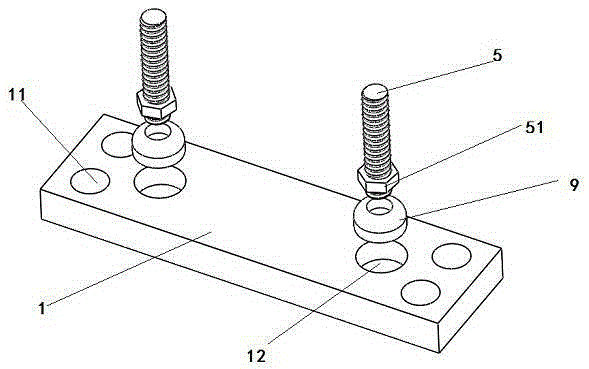

[0017] A new energy passenger car frame welding fixture, including a base 1, a U-shaped table 2, a splint 3, a threaded ejector rod 4, an adjusting screw 5, a connecting rod 6, a roller 7, a positioning pin 8, and a screw disk 9, and the base 1 is fixed on On the welding workbench, there are four fixed holes 11 symmetrically arranged above it, and two symmetrical blind holes 12 are arranged in the middle of the base 1, and a rotatable screw disk 9 is arranged on the blind hole 12, and an adjusting screw is fixed in the screw disk 9 5. A nut 51 is fixed at the joint position between the lower end of the adjusting screw 5 and the screw plate 9, and the upper end of the adjusting screw 5 is respectively connected with the threaded holes 23 below the U-shaped table 2. The front and rear sides of the U-shaped table 2 are symmetrically prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com