Automatic material tray lifting, clamping and translation mechanism

An automatic lifting and translation mechanism technology, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low work efficiency, high labor intensity, time-consuming and laborious, etc., to reduce labor costs and operation intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

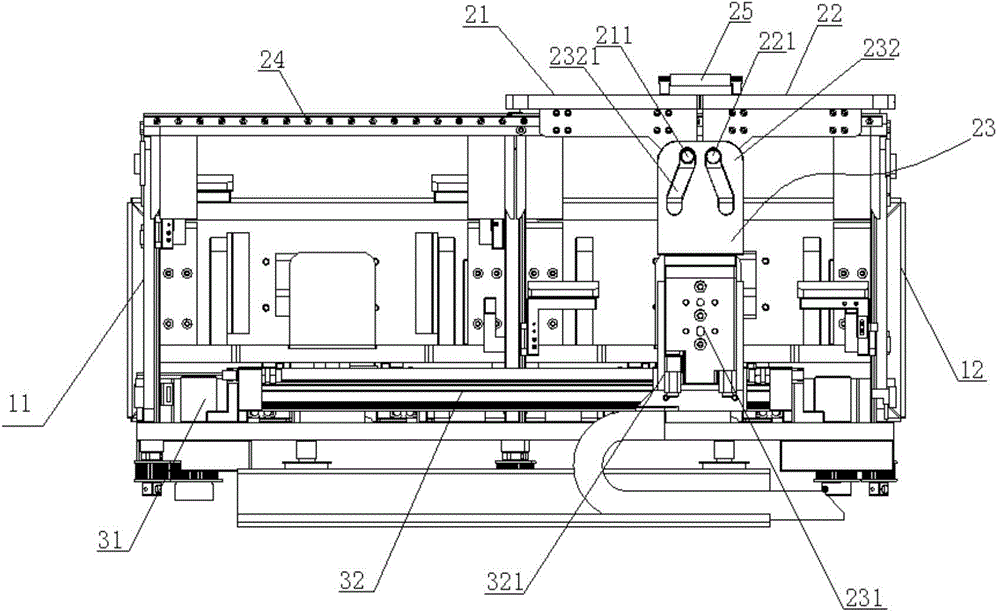

[0033] Terms such as "upper", "lower", "left", "right", "front", "rear", and "middle" cited in the present invention are for the convenience of description, and figure 1 or figure 2 The views are drawn for reference, rather than limiting the scope of the present invention. Changes or adjustments of their relative relationships shall also be regarded as the scope of the present invention without substantive changes in the technical content.

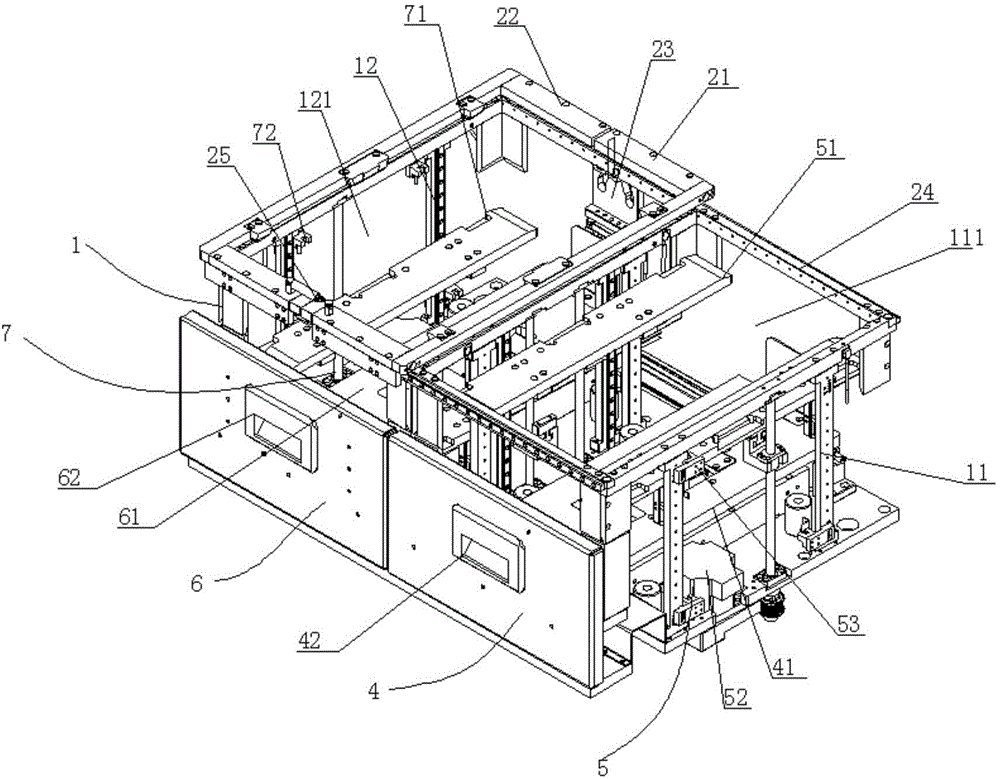

[0034] Such as figure 1 and figure 2 As shown, a tray automatic lifting and clamping translation mechanism includes a frame 1, a tray clamping device 2 and a tray translation device 3, and the frame includes a loading frame 11 and a blanking frame 12 arranged adjacently in sequence, The middle part of the feeding frame is formed with a feeding space 111, and the front side of the feeding frame is provided with a feeding drawer 4 for a drawer-type bearing tray, and the bottom of the loading frame is provided with a material tray for dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com